Upgrading a Batten Headed 455 originally built by Joe Mondello 20+ years ago

#161

Thank you for the input Mark, have you used these lobes in anything yet besides our engine? Do you have some dyno graphs of those runs with the morel lifters that you could share so we can compare? Were they doing the same thing to your BSFC numbers because of bounce?

Also, how much would a set of those hylift lifters run?

We obviously want to fix the issues, I just donít want to dump another $1000 into it with the same results at the outcome.

Also, how much would a set of those hylift lifters run?

We obviously want to fix the issues, I just donít want to dump another $1000 into it with the same results at the outcome.

Toplines run anywhere from $340-375 depending on the style and valving.

if you remember you wanted that amount of lift, I remember going with something less in the beginning. But 235@.050 even in a 9.5:1 455 should run fine.

However I still believe thatís not the basis of your problem.

But Vortecpro believes otherwise so Iíd just do what he says then.

#162

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Mark / Vortecpro wrote:

Its not the lifters................235@.050......640 lift I believe thats the problem, and then theres the 115 cranking compression. As far as Morel lifters go I've never seen a Morel lifter down on power to another lifter brand, (and I've done a lot of testing) I've heard noise in some cases, but not in Ryans case.

Bernhard wrote:

Do you think the cam is bleeding off to much cylinder pressure or is it a sealing issue?

Did you have a chance to do a leak down test?

Its not the lifters................235@.050......640 lift I believe thats the problem, and then theres the 115 cranking compression. As far as Morel lifters go I've never seen a Morel lifter down on power to another lifter brand, (and I've done a lot of testing) I've heard noise in some cases, but not in Ryans case.

Bernhard wrote:

Do you think the cam is bleeding off to much cylinder pressure or is it a sealing issue?

Did you have a chance to do a leak down test?

#163

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Yes I’ll see what I can find.

Toplines run anywhere from $340-375 depending on the style and valving.

if you remember you wanted that amount of lift, I remember going with something less in the beginning. But 235@.050 even in a 9.5:1 455 should run fine.

However I still believe that’s not the basis of your problem.

But Vortecpro believes otherwise so I’d just do what he says then.

https://www.tapatalk.com/groups/real...fi-t13676.html

Last edited by VORTECPRO; February 4th, 2019 at 04:38 PM.

#164

This isn't your problem, nobody says its your fault. The engine does run fine, despite the valve float, it just doesn't make any power NA, and peaks at a low RPM. Ryan and his father intend on racing the car so RPM and HP are important. The valve float situation has to be fixed.

#165

Cutlasefi wrote:

Fine but the cam isnít causing the valve float.

Bernhard wrote:

This question is not to lay blame!!

But does not cam ramp profile effect valve float?

From what I have read and through talking to cam manufacturers ramp profile can also effects valve float.

The valve spring pressure is not just selected based on rpm and valve lift but also how aggressive the cam ramp profiles are.

Fine but the cam isnít causing the valve float.

Bernhard wrote:

This question is not to lay blame!!

But does not cam ramp profile effect valve float?

From what I have read and through talking to cam manufacturers ramp profile can also effects valve float.

The valve spring pressure is not just selected based on rpm and valve lift but also how aggressive the cam ramp profiles are.

#166

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Cutlasefi wrote:

Fine but the cam isn’t causing the valve float.

Bernhard wrote:

This question is not to lay blame!!

But does not cam ramp profile effect valve float?

From what I have read and through talking to cam manufacturers ramp profile can also effects valve float.

The valve spring pressure is not just selected based on rpm and valve lift but also how aggressive the cam ramp profiles are.

Fine but the cam isn’t causing the valve float.

Bernhard wrote:

This question is not to lay blame!!

But does not cam ramp profile effect valve float?

From what I have read and through talking to cam manufacturers ramp profile can also effects valve float.

The valve spring pressure is not just selected based on rpm and valve lift but also how aggressive the cam ramp profiles are.

I think its important to also note I had a car with virtually the same exact dyno data as Ryans, this car at 3500 pounds ran 11.35 @ 2200 feet elevation track, although it had no valve float issues to 5800 plus RPM. I will post this dyno sheet if I can find it.

Last edited by VORTECPRO; December 25th, 2018 at 04:53 PM. Reason: picture

#167

But Iím not sure why everyone keeps saying itís the lobes. Yeah itís the lobes when you have the wrong springs and/or lifters. Do you think these lobes havenít ever been used before successfully? Theyíre proven Howardís cam lobes. Iíve bought this same SADI core from Comp before and had Howardís grind it, no issues.

Call and ask for Eric if you like. He and I talked about this grind specifically, and we both thought the lift was a bit excessive.

Just hope Ryan gets what he paid for.

Last edited by cutlassefi; December 25th, 2018 at 05:49 PM.

#168

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

I’ll bet that you can.

But I’m not sure why everyone keeps saying it’s the lobes. Yeah it’s the lobes when you have the wrong springs and/or lifters. Do you think these lobes haven’t ever been used before successfully? They’re proven Howard’s cam lobes. Call them if you have questions.

Whatever.

463 EFI Build

469 Carb/EFI build

463 Build

455 build

These 4 builds of yours seem to have the same power curve as Ryan's. Maybe it is the lobes........

Last edited by VORTECPRO; December 25th, 2018 at 05:50 PM.

#169

And the 469 carb build Iím thinking of made 571. Same curve, really? And the 403 I just did made 491 well into the 5000ís with C heads and 9.5:1. Same curve? Really? They seem to be making better power higher up than this build.

Again you're barking up the wrong tree.

I'm done here. Best of luck Ryan. I really hope you get it figured out.

Last edited by cutlassefi; December 25th, 2018 at 05:59 PM.

#170

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Same RPM peak. what was the VE on that particular test that made 571? In fact could you post up that dyno sheet, I've got some questions on that one.

https://www.tapatalk.com/groups/real...fi-t13676.html

Last edited by VORTECPRO; February 4th, 2019 at 04:39 PM.

#171

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Batten Runner/Ryan

I'am sure you noticed when we made a pull on your engine and printed the data-about 8 pages of supporting data came out of the printer showing how 473 HP was arrived at during the test. If you could post your VE that would be helpful as well, thanks.

I'am sure you noticed when we made a pull on your engine and printed the data-about 8 pages of supporting data came out of the printer showing how 473 HP was arrived at during the test. If you could post your VE that would be helpful as well, thanks.

#172

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Those all had Lunatis, read the text.

And the 469 carb build I’m thinking of made 571. Same curve, really? And the 403 I just did made 491 well into the 5000’s with C heads and 9.5:1. Same curve? Really? They seem to be making better power higher up than this build.

Again you're barking up the wrong tree.

I'm done here. Best of luck Ryan. I really hope you get it figured out.

1. Fuel flow A&B

2. BSFC

3. VE

4. BMEP.

But still these tests you've given as an example all seem to peak at a low RPM. I'am just trying to learn why, as I haven't seen this before. In my testing the Lunati Voodoo cams were way to aggressive with a hyd roller lifter and could not be made to RPM with ANY hyd roller lifter and spring package.

Last edited by VORTECPRO; December 25th, 2018 at 06:38 PM.

#173

Merry Christmas to all!!

Like Vortecpro says, I am not a quitter on this.

With 20 dyno pulls, we proved the shortblock is in great shape and ready to go to work.

I think it is now time to explore the potential locked away in the mildly ported heads with little intake valves, and to acquire a cam grind that can be controlled by moderate/ normal spring rates without bouncing the valves off their seats on closing.

At least we have Cometic head gaskets that can work multiple torque cycles....

Hopefully, we can regrind this cam core and reuse another part...

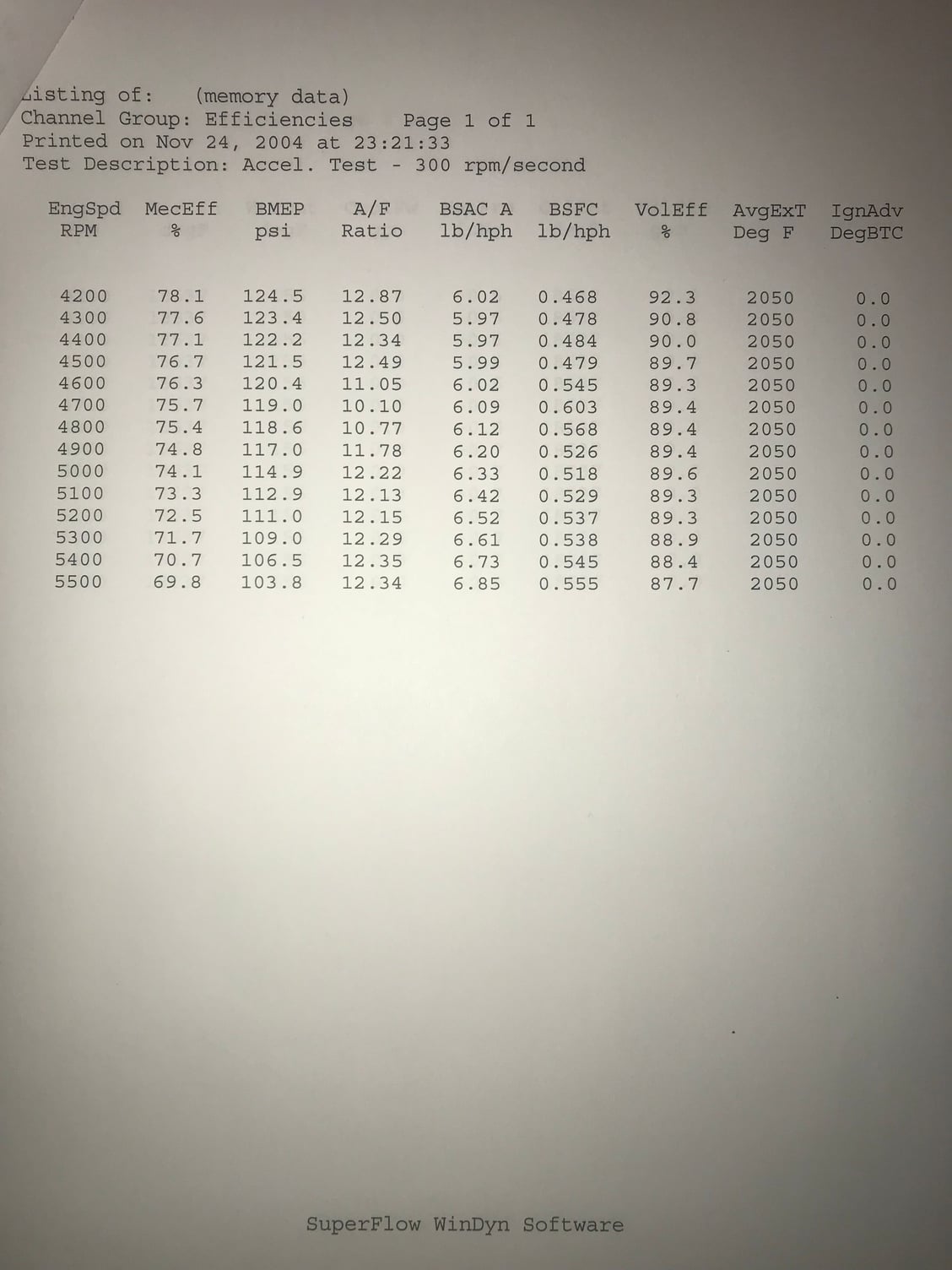

Here is the page with the VE results:

Last edited by Battenrunner; December 25th, 2018 at 08:01 PM.

#174

I know this is a apples to oranges comparison. When I spoke to Bullet cams about running a dwell lobe cam profile I was surprised how much spring pressure was required to run such a profile.

The valve spring pressure required to run the dwell lobe, caused lifter issues that required special tool steel lifters or ceramic disc lifter to deal with the increased pressure.

Would it be fare to say that the existing spring pressure and roller lifters are not working well with this cam lobe profile thus causing valve float at much lower rpm than one would expect?

I look forward to seeing the build progress.

Thanks for sharing.

Merry Christmas

The valve spring pressure required to run the dwell lobe, caused lifter issues that required special tool steel lifters or ceramic disc lifter to deal with the increased pressure.

Would it be fare to say that the existing spring pressure and roller lifters are not working well with this cam lobe profile thus causing valve float at much lower rpm than one would expect?

I look forward to seeing the build progress.

Thanks for sharing.

Merry Christmas

#175

Yes, they do make more power at least according to that dyno, I would like to see the supporting data such as

1. Fuel flow A&B

2. BSFC

3. VE

4. BMEP.

But still these tests you've given as an example all seem to peak at a low RPM. I'am just trying to learn why, as I haven't seen this before. In my testing the Lunati Voodoo cams were way to aggressive with a hyd roller lifter and could not be made to RPM with ANY hyd roller lifter and spring package.

1. Fuel flow A&B

2. BSFC

3. VE

4. BMEP.

But still these tests you've given as an example all seem to peak at a low RPM. I'am just trying to learn why, as I haven't seen this before. In my testing the Lunati Voodoo cams were way to aggressive with a hyd roller lifter and could not be made to RPM with ANY hyd roller lifter and spring package.

And again for the last time, that build had Lunati VooDoo lobes as well, the right springs and the Topline-Hylift A-2347S lifter. Ran to over 6000 no problem.

But thatís fine, waste Ryanís money by just throwing parts at it, regrinding the cam etc. Wouldn't it be better to start by verifying itís float in the first place? Whatever.

Again best of luck Ryan

#176

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Look up Madmax 480 build. Everything is posted in that thread.

And again for the last time, that build had Lunati VooDoo lobes as well, the right springs and the Topline-Hylift A-2347S lifter. Ran to over 6000 no problem.

But that’s fine, waste Ryan’s money by just throwing parts at it, regrinding the cam etc. Wouldn't it be better to start by verifying it’s float in the first place? Whatever.

Again best of luck Ryan

Last edited by VORTECPRO; December 26th, 2018 at 05:15 AM.

#177

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

I know this is a apples to oranges comparison. When I spoke to Bullet cams about running a dwell lobe cam profile I was surprised how much spring pressure was required to run such a profile.

The valve spring pressure required to run the dwell lobe, caused lifter issues that required special tool steel lifters or ceramic disc lifter to deal with the increased pressure.

Would it be fare to say that the existing spring pressure and roller lifters are not working well with this cam lobe profile thus causing valve float at much lower rpm than one would expect?

I look forward to seeing the build progress.

Thanks for sharing.

Merry Christmas

The valve spring pressure required to run the dwell lobe, caused lifter issues that required special tool steel lifters or ceramic disc lifter to deal with the increased pressure.

Would it be fare to say that the existing spring pressure and roller lifters are not working well with this cam lobe profile thus causing valve float at much lower rpm than one would expect?

I look forward to seeing the build progress.

Thanks for sharing.

Merry Christmas

I think this thread explains it ALL. 455 build Cutlass EFI

Looks like 80 Rocket had the same questions I do............................

https://www.tapatalk.com/groups/real...fi-t13676.html

Last edited by VORTECPRO; February 4th, 2019 at 04:40 PM.

#178

#179

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

#181

If it'll load I'm showing another build I did. It's a 3x2 447c.i. BBO with Procomp heads, custom piston yielding 10.5:1, a Lunati custom hyd roller cam with Voodoo lobes, Topline-Hylift lifters, and Crane 99893 springs. The same valvetrain pieces I use most often. As you can see it's a rock solid build as far as bsfc goes.

Ryan, I'm doing this to help you and I hope it is of some help in solving your power issues. I understand Vortecpro has been a big help to you but he's been a real horses *** to me from day one and I'm not sure why. Check out his posts on here for yourself. He's condescending. rude and has basically doubted everything I've ever posted. I've even had to tell him repeatedly to lose my email address. Amazingly he pm''d me a couple months ago wanting a price on pistons, go figure. But I refused to help him, as I want nothing to do with him, ever. He's a whack job imo.

Vortecpro, years ago before all the lifter companies started using the LS body, the roller lifters for Olds weren't of the best quality. They would adjust fine but if you used an aggressive profile they would distort during lift, bleeding off in the process, and getting worse as rpms' increased. But of course you knew all this already because you're an effen know it all. And btw I've never done any Olds build that's made 650tq. As usual you're talking out of both sides of your mouth.

Please don't acknowledge me in any way as I'm done with this thread for good.

Thank you.

Ryan, I'm doing this to help you and I hope it is of some help in solving your power issues. I understand Vortecpro has been a big help to you but he's been a real horses *** to me from day one and I'm not sure why. Check out his posts on here for yourself. He's condescending. rude and has basically doubted everything I've ever posted. I've even had to tell him repeatedly to lose my email address. Amazingly he pm''d me a couple months ago wanting a price on pistons, go figure. But I refused to help him, as I want nothing to do with him, ever. He's a whack job imo.

Vortecpro, years ago before all the lifter companies started using the LS body, the roller lifters for Olds weren't of the best quality. They would adjust fine but if you used an aggressive profile they would distort during lift, bleeding off in the process, and getting worse as rpms' increased. But of course you knew all this already because you're an effen know it all. And btw I've never done any Olds build that's made 650tq. As usual you're talking out of both sides of your mouth.

Please don't acknowledge me in any way as I'm done with this thread for good.

Thank you.

Last edited by cutlassefi; December 26th, 2018 at 03:06 PM.

#182

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Can you post up the VE page of this dyno test?469 Carb/EFI build

https://www.tapatalk.com/groups/real...fi-t13676.html

https://www.tapatalk.com/groups/real...fi-t13676.html

Last edited by VORTECPRO; February 4th, 2019 at 04:40 PM.

#183

Hey Ryno. Did you try more timing to see how it affected the BSFC and AFR? Just curios if you are suffering from incomplete burn. Kinda a long shot at that RPM but just wondering. You remember. That thing wont run with less than 50 degree timing

#186

yep, it didnt really seem to care one way or the other with more or less timing, it was just blah everywhere....

#187

If you look you should have material transfer from the locks to the retainer. Maybe, if you have enough run time on the engine. You should spring for the tool steel retainers with the super 7 locks.(I have a set of the locks, your welcome to them)(but you pay shipping). Lighten up your valve-train as much as you safely can. Get it?? SPRING for the retainers  I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.

I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.

I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.

I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.

#188

If you look you should have material transfer from the locks to the retainer. Maybe, if you have enough run time on the engine. You should spring for the tool steel retainers with the super 7 locks.(I have a set of the locks, your welcome to them)(but you pay shipping). Lighten up your valve-train as much as you safely can. Get it?? SPRING for the retainers  I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.

I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.

I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.

I would like to hear more thoughts on the correlation between the BSFC and the AFR numbers. Besides the obvious.these are the Isky tool room, expensive retainers, and I believe they are the super 7 degree locks also. I remember them being +.050 on the height

I know that these are the only retainers made that correctly fit these particular springs, as Isky was the spring manufacturer and these were some new old stock retainers that Isky had to dust off to sell to us, as they donít even list the part number anymore. Of course, they priced them like they were from a museum.....

Looks like we we will be changing the springs, retainers, and locators also anyways...

now, letís see if we can get these old Battens to flow some air...

Last edited by Battenrunner; December 26th, 2018 at 07:35 PM.

#189

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

"Wouldn't it be better to start by verifying it’s float in the first place? Whatever"

Looks like valve float to me, of course my dyno data told me it was valve float right from the start............starting at 4700 RPM.

#190

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

these are the Isky tool room, expensive retainers, and I believe they are the super 7 degree locks also. I remember them being +.050 on the height

I know that these are the only retainers made that correctly fit these particular springs, as Isky was the spring manufacturer and these were some new old stock retainers that Isky had to dust off to sell to us, as they don’t even list the part number anymore. Of course, they priced them like they were from a museum.....

Looks like we we will be changing the springs, retainers, and locators also anyways...

now, let’s see if we can get these old Battens to flow some air...

Last edited by VORTECPRO; December 26th, 2018 at 08:03 PM.

#191

I haven't used isky before but they don't look like the tool steel retainers I seen before . Oh well.

#192

You don't need to change any of those parts, much less the lifters, I've run Morel hyd roller lifters 7500 RPM in race conditions with zero problems, made 900 track proven HP with Morel hyd roller lifters, 880 plus dyno HP with supporting data to prove the HP, 7100 RPM HP peaks. And for the record 148.8 MPH @ 3600 pounds with Morel hyd roller lifters. The cam needs to go........

#194

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

The customer made me do it-I don't recommend it, it was hard on the springs. In fact the hyd roller kept him out of the 8s, I remember saying "what if the car runs 9 ohs, 8.80s with the solid roller"

9.04 @ 3600 pounds NA 10 inch slick

148.8 MPH @ 3600 pounds NA

7000 RPM through the lights, 228 @ .050 hyd roller Morel lifters, stamped steel rockers, 1.250 single springs, peanut port 236 heads. Peaked @ 5800 RPM, down 10 HP @ 6400 RPM, NO valve float.

10.34 @ 3720 NA Best

126.2 @ 3720 NA Best

https://www.chevelles.com/forums/13-...drag-test.html

148.8 MPH @ 3600 pounds NA

7000 RPM through the lights, 228 @ .050 hyd roller Morel lifters, stamped steel rockers, 1.250 single springs, peanut port 236 heads. Peaked @ 5800 RPM, down 10 HP @ 6400 RPM, NO valve float.

10.34 @ 3720 NA Best

126.2 @ 3720 NA Best

https://www.chevelles.com/forums/13-...drag-test.html

Last edited by VORTECPRO; December 27th, 2018 at 03:25 AM.

#195

Now that it seems we have a solid shortblock, we are going to massage the heads and install larger intake valves, and likely replace exhaust seats and turn those exhaust valves smaller.

Also, because we were trying to make sure everything held together well during the Dyno sessions, we didnít do anything with the heads.

The partial tear-down shows everything working well overall, aside from valvetrain instabilities that are soon to be remedied.

So, for starters, aside from the small intake valves, what else can you all see that is restricting flow in the heads....

I will give a hint, the bore size is 4.185.....

Last edited by Battenrunner; January 4th, 2019 at 04:27 PM.

#196

Now that it seems we have a solid shortblock, we are going to massage the heads and install larger intake valves, and likely replace exhaust seats and turn those exhaust valves smaller.

Also, because we were trying to make sure everything held together well during the Dyno sessions, we didnít do anything with the heads.

The partial tear-down shows everything working well overall, aside from valvetrain instabilities that are soon to be remedied.

So, for starters, aside from the small intake valves, what else can you all see that is restricting flow in the heads....

I will give a hint, the bore size is 4.185.....

#198

Through my job I have been fortunate enough to attend induction tuning classes instructed by Darin Morgan. One thing we learned in that class was the importance of air speed. When air exits the intake port past the valve into the chamber it stops. That's a bad thing. To keep the air moving you want to keep the valve close enough to the chamber to speed the air up but not close enough to reduce flow. Most of us have been taught to pull the chamber away from the valves as much as the bore will allow, and unfortunately that is wrong. We see this displayed in aftermarket heads with very efficient chambers. I'm not saying that we should not unshroud the valves . I'm saying that it should be done very carefully and tested along the way.

#199

Some surprises to come in the next few weeks on the heads.... the slack in the valve guides on one of the intakes was terrible, and there was more than .009 of runout on the seat that Mark measured.... New valve guides and new exhaust seats to come next by VortecPro.

For now, we are making room for the larger intake valves... I turned these exhaust valves tonight after I got home from work.... let me tell you what, Manley severe duty valves are made of some tough alloy, and it does get harder as you increase the temp, believe me!

These 1.71 valves were cut down to be ~1.635 /1.6345 inches...NOW THAT IS WHAT I CALL A MARGIN! Haha

Manley 2.125 Race Flo intake valves are on the way, and from the way the ports look, should work great in these heads!

Last edited by Battenrunner; January 9th, 2019 at 09:36 PM.