Home Porting Techniques

#441

On a factor olds head it ends up being .0055"/CC. On Edelbrock and ProComp its .006"/CC. Believed me when I tell you that I've CC'd and milled enough heads that these numbers work out to being as close to perfect as your gonna get.

Also keep the grease sealing ring for the plexiglass as thin as you possibly can. Its easy to have .006" of grease to give you an added CC that really isn't there.

Also keep the grease sealing ring for the plexiglass as thin as you possibly can. Its easy to have .006" of grease to give you an added CC that really isn't there.

#442

If you use to much grease when you put the cover over the chamber the excess grease will sqwish into the chamber and you wont have accurate data.Also make sure that you fill the burret even with the line and not over as in the pic.

accuracy is key or it doesnt make sence to even do it.

Greg

accuracy is key or it doesnt make sence to even do it.

Greg

#443

Thanks for posting that information Smitty, now I can do the math. Greg you are 100% correct. Accuracy is key or why bother doing it? As I said this was my first ever experience with doing this. It wasn't hard, but I do realize there's little tricks to everything.

So using the information we have, we believe these #6 heads were shaved .030" so .030/.0055 = 5.45

We take the stock chamber @ 70CC - 5.45 = 64.55

The current combustion chamber is 67CC - 64.55 = 2.45CC

So guys, I know my methods may not be 100% accurate, but I'm just trying to get an idea of how big of an affect polishing the combustion chamber will have on your final compression ratio. Ideally we should have measured the combustion chamber before, and after work. We're still assuming the heads had a .030" shave. The heads may have started out closer to 2.220" which would have been a .050" whack. Copper's engine has been zero decked, with flat top pistons, bored .030 over, and assuming FelPro head gaskets @ .040". So if I plug these figures into the compression ratio calculator-

https://www.rbracing-rsr.com/compstaticcalc.html

At 67CC it calculates out to be 10.62:1 ratio. That's pretty ideal for pump gas performance.

At 64.55CC it calculates out to be 10.94:1

So in conclusion this tells me just polishing the combustion chamber will result in a compression ratio drop of .3:1 that seems like a lot.

What amazes me more is how easy it is to bump the compression ratio back up by using a thinner head gasket. With the 67CC formula if we used the .025" thick Commetics that would put our static compression ratio at 11.05:1

So using the information we have, we believe these #6 heads were shaved .030" so .030/.0055 = 5.45

We take the stock chamber @ 70CC - 5.45 = 64.55

The current combustion chamber is 67CC - 64.55 = 2.45CC

So guys, I know my methods may not be 100% accurate, but I'm just trying to get an idea of how big of an affect polishing the combustion chamber will have on your final compression ratio. Ideally we should have measured the combustion chamber before, and after work. We're still assuming the heads had a .030" shave. The heads may have started out closer to 2.220" which would have been a .050" whack. Copper's engine has been zero decked, with flat top pistons, bored .030 over, and assuming FelPro head gaskets @ .040". So if I plug these figures into the compression ratio calculator-

https://www.rbracing-rsr.com/compstaticcalc.html

At 67CC it calculates out to be 10.62:1 ratio. That's pretty ideal for pump gas performance.

At 64.55CC it calculates out to be 10.94:1

So in conclusion this tells me just polishing the combustion chamber will result in a compression ratio drop of .3:1 that seems like a lot.

What amazes me more is how easy it is to bump the compression ratio back up by using a thinner head gasket. With the 67CC formula if we used the .025" thick Commetics that would put our static compression ratio at 11.05:1

#444

I have 3cc probes dave. That's why I got that 10.25 to 1 figure. The flat top piston engine is in my 72 right now that has the pistons sitting .025 in the cylinders. Also .030 over

Last edited by coppercutlass; March 20th, 2014 at 09:12 AM.

#445

I figured the cc would drop a few points after the polish, and using a thinner head gasket would loose the perfect quench (if that is actually something). A lot of people say it matters... what say you??

#446

It's more than a quest for good quench and higher comp. You also need to observe

a min piston to head distance. A piston to head gap of .040 to .045 would be a good number for quench and piston to head clearance. A gasket of .020 would put you right where you want to be. The gap allows for piston rock, rod stretch, rod bearing clearance, etc.

It's insurance that the piston doesn't smack the head.

a min piston to head distance. A piston to head gap of .040 to .045 would be a good number for quench and piston to head clearance. A gasket of .020 would put you right where you want to be. The gap allows for piston rock, rod stretch, rod bearing clearance, etc.

It's insurance that the piston doesn't smack the head.

#447

Lars I'm not so sure we have a perfect quench with our Olds heads. In my opinion, after polishing the chamber, you're basically moving it slightly further away from the piston. By using a slightly thinner head gasket, you're just putting it back where it originally was.

#448

It's more than a quest for good quench and higher comp. You also need to observe

a min piston to head distance. A piston to head gap of .040 to .045 would be a good number for quench and piston to head clearance. A gasket of .020 would put you right where you want to be. The gap allows for piston rock, rod stretch, rod bearing clearance, etc.

It's insurance that the piston doesn't smack the head.

a min piston to head distance. A piston to head gap of .040 to .045 would be a good number for quench and piston to head clearance. A gasket of .020 would put you right where you want to be. The gap allows for piston rock, rod stretch, rod bearing clearance, etc.

It's insurance that the piston doesn't smack the head.

113-1393_IMG.jpg

#449

In dome styles of combustion chamber quench makes a big difference. On others not so much. On a chamber like the Olds which is shallow compared to most it doesn't seem to be as big a deal.

How far does the dome stick out of the block on that piston. I'd be sure to clay them all in a mock up to be sure you have clearance at all points.

How far does the dome stick out of the block on that piston. I'd be sure to clay them all in a mock up to be sure you have clearance at all points.

#450

FYI~There are other ways to make compression other than a Mountain with sharp edges...Wow! lol

#451

Mock up your short block, put the head on it without a gasket, turn it over if you can and see where and how much contact it makes.massage the domes untill they fit each chamber without contact. Its also pretty impossible to get big compression on a small cubic inch engine without a dome unless your combustion chambers are very tiny.More so with a stock castiron head.

Greg

Greg

Last edited by rcktdoc; March 25th, 2014 at 09:25 AM.

#453

What are you calling "big"? Like Wise stated, there are other ways. Add a little bore, add a little stroke, do a little milling. Doing quick match, a 350 bored to 4.125 with a flat top .015 in the hole, .028 gasket, 3.5" stroke, and a 64cc head you get a tad over 11.5 to 1. How much do you need?? Not to mention the much better flame travel with a flat top, IMHO.

Last edited by captjim; March 25th, 2014 at 11:25 AM.

#454

I'm glad someone else said it. Are you planning on de-burring those?? The whole thing looks like a nightmare in the making. No offense, but if you have never CC'd a chamber, are you prepared for the complications of running that piston? I am assuming a BIG cam goes with it. Your piston-to-valve better be right, your springs better be perfect, float a valve just a tad and it will suck a valve.

#456

Lots of guys going plenty fast with less, but whatever works for you. Not sure the "was talking 350 cuin" means? I was talking about a 350 block and crank bored and the crank offset ground .115

#457

I have done a few 400- 406 cuin bored & stroked, to get 15-1 needed domes. Ive done plenty of small blocks with big compression. They all needed small chambers and domes. Im sure if hes got a dome as big as pictured hes looking for max compression. The dome needs to be finished and quench at the minimum or your just wasting your time.

Greg

Greg

#458

Greg

#459

My point is that depending on his goals, there might be an easier way to do it than those huge domed pistons and all the hassles that go with it. At some point, the heads will probably be the limiting factor.

#460

Well its completely evident that he already owns the pistons so instead of trying to reengineer his compolete project it might be simpler and cheaper for him to help him use what he has.

Greg

Greg

#462

#463

The flame will get there,I have run big domes like that before and made great power. Because of the flat valve angle of the olds you need to have large domes on smaller cubic inch engines with large cam shafts. The valve relief is such that it uses up a lot of ccs and you need to make up for that somewhere. They used domes exactly like that back in the day when olds was running in NASCAR.

Greg

Greg

#464

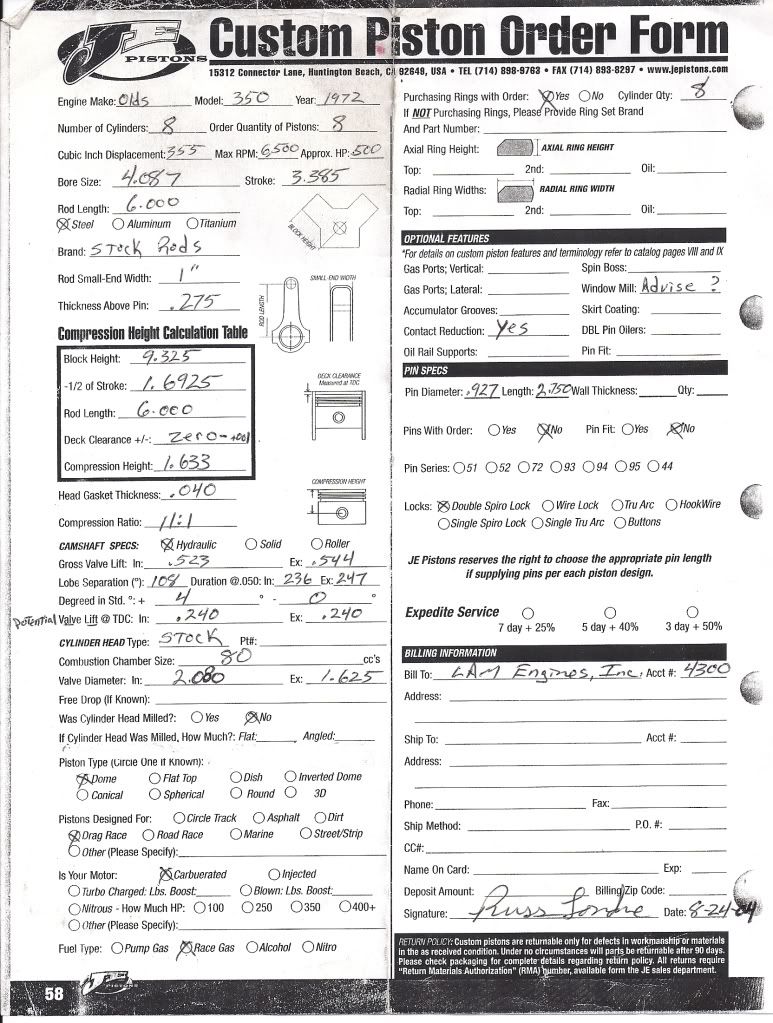

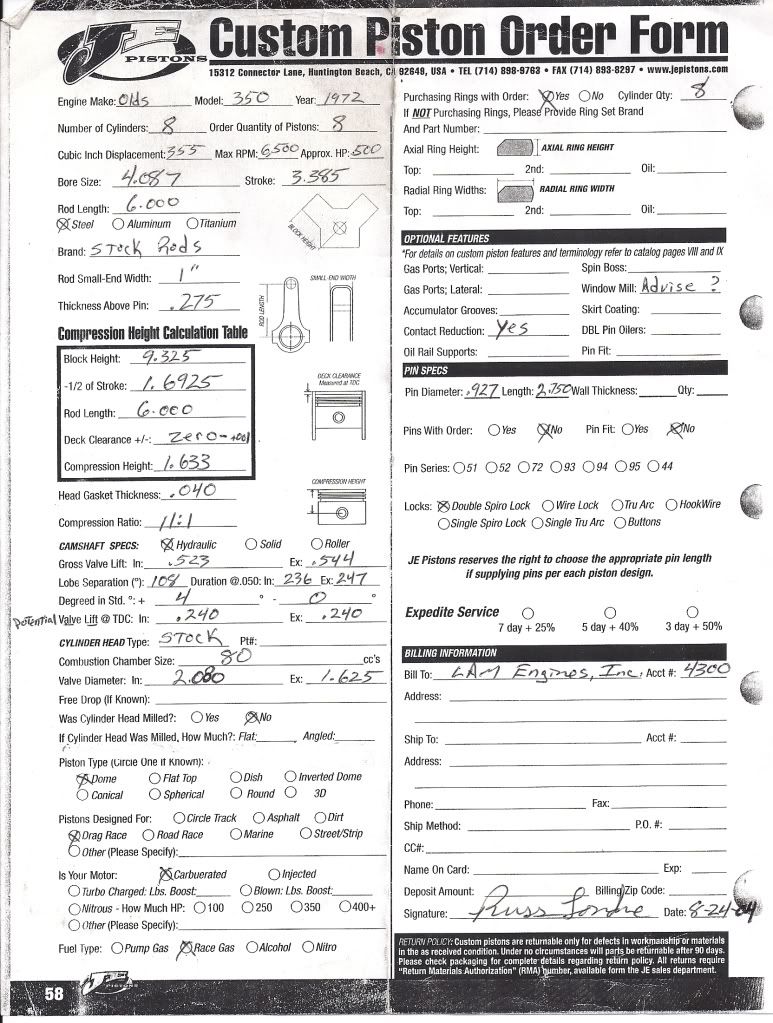

My 355 Build

Ok guys, I appreciate all the concerns about this dome piston engine. I feel I should give you guys some back ground and details on this build. Two years ago I tried to sell this engine at a thousand dollar loss with no serious nibbles. Here's the story-------

Olds 350 High Performance short block

Back in 2004 a friend of mine wanted to build a drag car. He was fresh out of high school and worked at my shop as a clean up kid. He didn't know much about mechanicals, but he seemed eager to learn. I gave him a nice '86 Cutlass with a fresh Turbo 400 and a 12 bolt rear end. I also gave him a 1972 350 engine along with a 330 crank and some Ga BB heads. I showed him what needed to be done to port them but he didn't get too far. I finished the heads for him. I probably have close to 80 hours into them. I bought a bunch of parts for this engine and paid for all the machine work. My friend went into the military and lost interest. He came back from Iraq, got married and had two kids. The car was scrapped but I got the trans and I picked up the engine from the machine shop. I kinda lost track of how much money that I sunk into this thing, so I got out all the receipts and put together this spread sheet. The compression may be too high for pump gas, and I really think it's not going to be very streetable. My car is set up for a BB so I really have no need for this engine. The block is from 1970-1972. The crank and flexplate are original from my 1967 330. I have plenty of core heads if someone wants to purchase a complete running engine that can be arranged. For anyone who is really interested , I can e-mail all the photos taken and blue print data compiled during assembly. I will also throw in a stock oil pan, a split timing cover and an HEI distributor with low miles.

Olds 350 CI Race Engine

1972 350CI engine block core

1967 330 steel crank core

1967 Flex plate

1972 Damper

JE Pistons Custom 2300077 $680.75

Rings J100F84080-5 $100.00

Rod bearings 02-5029 $60.00

Main Bearings MS805P20 $60.00

Rod bushings 02-5029 $40.00

(2) Heavy metal slug 1”X1” $70.00

ARP rod bolt RB-200 $58.00

Freeze plug kit FP-640 $14.00

Race Cam Bearings RCB-499 $69.00

Gasket Set GS-550 $95.00

High Volume Oil Pump SP-754 $69.00

Bolt on pick up PU-3 $35.00

J&S 5 Main Halo $250.00

J&S Main Stud kit $85.00

Custom modern grind cam/ lifters $265.00

Machine Work Performed by LAM Racing Engines

Install rod bushings, Fit/ assemble rods & pistons,

final polish rod beams, Recondition rods with ARP bolts-

includes R&R bolts, machine oil relief grooves in rods,

deck block, piston height + .0001,

Balance rotating assembly, regrind crank

Rods - .020 Mains - .020, install slugs of heavy metal (mill),

Install main studs, mill for main girdle (halo) to 2.175 depth of caps

Dial bore gauge main bearing bores, low limit to middle of spec,

Final wash block and install cam bearings & freeze plugs, check main

bearing clearance and ring end gaps. Total machine shop services - $1311

Final assembly and measurement performed by Dane Lulling of

Mild to Wild Racing $400

total investment- $3825.75

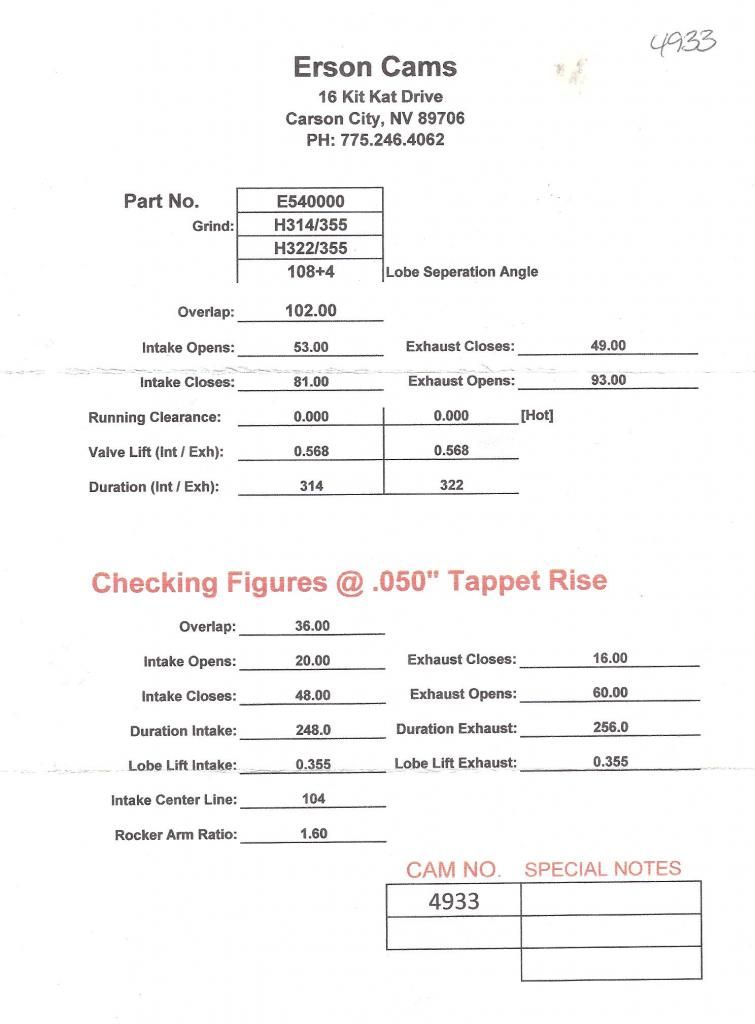

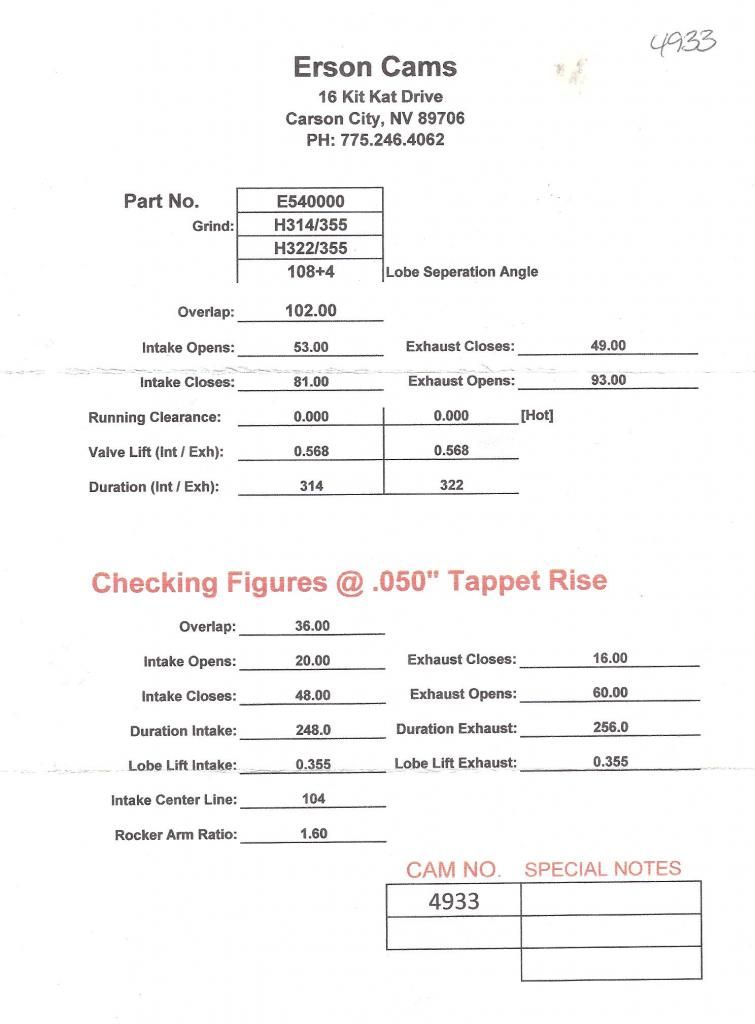

So there you have it. I have decided to finish the GA heads with some Stainless steel valves and then finish with the mock up and clearance checking. I have everything parts wise needed to finish this engine. I have an MSD billet distributor, a ported Victor intake, and a Demon 850 CFM carb. Since nobody wanted to purchase this engine I'm going to break in the cam on a running engine stand and then I plan to sponsor a couple local racers to flog this engine and get some data. Mark (Cutlass EFI) set me up with the cam & it will be a race fuel only engine. Here's some data sheets on the build:

scan0001-1.jpg

Olds350cam001.jpg

Smitty this short block has been bagged in storage under my bench for the last two years. The assembler did smooth the sharp edges on the pistons before final assembly. I will dig it out real soon and do some measuring for you. The piston spec sheet sais the dome is 18CC. I find that hard to believe. I'm going to use clay to check my clearances. I was also considering making a clay casting of the dome to CC it for myself.

When I plugged in the numbers to the compression calculator I came up with 11.3:1 when using an 80CC combustion chamber. It will be 12.26:1 if I milled the heads down to 74CC. This is with a .040 gasket. I think I will need all the chamber I can get so I wasn't planning on milling.

Olds 350 High Performance short block

Back in 2004 a friend of mine wanted to build a drag car. He was fresh out of high school and worked at my shop as a clean up kid. He didn't know much about mechanicals, but he seemed eager to learn. I gave him a nice '86 Cutlass with a fresh Turbo 400 and a 12 bolt rear end. I also gave him a 1972 350 engine along with a 330 crank and some Ga BB heads. I showed him what needed to be done to port them but he didn't get too far. I finished the heads for him. I probably have close to 80 hours into them. I bought a bunch of parts for this engine and paid for all the machine work. My friend went into the military and lost interest. He came back from Iraq, got married and had two kids. The car was scrapped but I got the trans and I picked up the engine from the machine shop. I kinda lost track of how much money that I sunk into this thing, so I got out all the receipts and put together this spread sheet. The compression may be too high for pump gas, and I really think it's not going to be very streetable. My car is set up for a BB so I really have no need for this engine. The block is from 1970-1972. The crank and flexplate are original from my 1967 330. I have plenty of core heads if someone wants to purchase a complete running engine that can be arranged. For anyone who is really interested , I can e-mail all the photos taken and blue print data compiled during assembly. I will also throw in a stock oil pan, a split timing cover and an HEI distributor with low miles.

Olds 350 CI Race Engine

1972 350CI engine block core

1967 330 steel crank core

1967 Flex plate

1972 Damper

JE Pistons Custom 2300077 $680.75

Rings J100F84080-5 $100.00

Rod bearings 02-5029 $60.00

Main Bearings MS805P20 $60.00

Rod bushings 02-5029 $40.00

(2) Heavy metal slug 1”X1” $70.00

ARP rod bolt RB-200 $58.00

Freeze plug kit FP-640 $14.00

Race Cam Bearings RCB-499 $69.00

Gasket Set GS-550 $95.00

High Volume Oil Pump SP-754 $69.00

Bolt on pick up PU-3 $35.00

J&S 5 Main Halo $250.00

J&S Main Stud kit $85.00

Custom modern grind cam/ lifters $265.00

Machine Work Performed by LAM Racing Engines

Install rod bushings, Fit/ assemble rods & pistons,

final polish rod beams, Recondition rods with ARP bolts-

includes R&R bolts, machine oil relief grooves in rods,

deck block, piston height + .0001,

Balance rotating assembly, regrind crank

Rods - .020 Mains - .020, install slugs of heavy metal (mill),

Install main studs, mill for main girdle (halo) to 2.175 depth of caps

Dial bore gauge main bearing bores, low limit to middle of spec,

Final wash block and install cam bearings & freeze plugs, check main

bearing clearance and ring end gaps. Total machine shop services - $1311

Final assembly and measurement performed by Dane Lulling of

Mild to Wild Racing $400

total investment- $3825.75

So there you have it. I have decided to finish the GA heads with some Stainless steel valves and then finish with the mock up and clearance checking. I have everything parts wise needed to finish this engine. I have an MSD billet distributor, a ported Victor intake, and a Demon 850 CFM carb. Since nobody wanted to purchase this engine I'm going to break in the cam on a running engine stand and then I plan to sponsor a couple local racers to flog this engine and get some data. Mark (Cutlass EFI) set me up with the cam & it will be a race fuel only engine. Here's some data sheets on the build:

scan0001-1.jpg

Olds350cam001.jpg

Smitty this short block has been bagged in storage under my bench for the last two years. The assembler did smooth the sharp edges on the pistons before final assembly. I will dig it out real soon and do some measuring for you. The piston spec sheet sais the dome is 18CC. I find that hard to believe. I'm going to use clay to check my clearances. I was also considering making a clay casting of the dome to CC it for myself.

When I plugged in the numbers to the compression calculator I came up with 11.3:1 when using an 80CC combustion chamber. It will be 12.26:1 if I milled the heads down to 74CC. This is with a .040 gasket. I think I will need all the chamber I can get so I wasn't planning on milling.

#465

Ok guys, I appreciate all the concerns about this dome piston engine. I feel I should give you guys some back ground and details on this build. Two years ago I tried to sell this engine at a thousand dollar loss with no serious nibbles. Here's the story-------

Olds 350 High Performance short block

Back in 2004 a friend of mine wanted to build a drag car. He was fresh out of high school and worked at my shop as a clean up kid. He didn't know much about mechanicals, but he seemed eager to learn. I gave him a nice '86 Cutlass with a fresh Turbo 400 and a 12 bolt rear end. I also gave him a 1972 350 engine along with a 330 crank and some Ga BB heads. I showed him what needed to be done to port them but he didn't get too far. I finished the heads for him. I probably have close to 80 hours into them. I bought a bunch of parts for this engine and paid for all the machine work. My friend went into the military and lost interest. He came back from Iraq, got married and had two kids. The car was scrapped but I got the trans and I picked up the engine from the machine shop. I kinda lost track of how much money that I sunk into this thing, so I got out all the receipts and put together this spread sheet. The compression may be too high for pump gas, and I really think it's not going to be very streetable. My car is set up for a BB so I really have no need for this engine. The block is from 1970-1972. The crank and flexplate are original from my 1967 330. I have plenty of core heads if someone wants to purchase a complete running engine that can be arranged. For anyone who is really interested , I can e-mail all the photos taken and blue print data compiled during assembly. I will also throw in a stock oil pan, a split timing cover and an HEI distributor with low miles.

Olds 350 CI Race Engine

1972 350CI engine block core

1967 330 steel crank core

1967 Flex plate

1972 Damper

JE Pistons Custom 2300077 $680.75

Rings J100F84080-5 $100.00

Rod bearings 02-5029 $60.00

Main Bearings MS805P20 $60.00

Rod bushings 02-5029 $40.00

(2) Heavy metal slug 1”X1” $70.00

ARP rod bolt RB-200 $58.00

Freeze plug kit FP-640 $14.00

Race Cam Bearings RCB-499 $69.00

Gasket Set GS-550 $95.00

High Volume Oil Pump SP-754 $69.00

Bolt on pick up PU-3 $35.00

J&S 5 Main Halo $250.00

J&S Main Stud kit $85.00

Custom modern grind cam/ lifters $265.00

Machine Work Performed by LAM Racing Engines

Install rod bushings, Fit/ assemble rods & pistons,

final polish rod beams, Recondition rods with ARP bolts-

includes R&R bolts, machine oil relief grooves in rods,

deck block, piston height + .0001,

Balance rotating assembly, regrind crank

Rods - .020 Mains - .020, install slugs of heavy metal (mill),

Install main studs, mill for main girdle (halo) to 2.175 depth of caps

Dial bore gauge main bearing bores, low limit to middle of spec,

Final wash block and install cam bearings & freeze plugs, check main

bearing clearance and ring end gaps. Total machine shop services - $1311

Final assembly and measurement performed by Dane Lulling of

Mild to Wild Racing $400

total investment- $3825.75

So there you have it. I have decided to finish the GA heads with some Stainless steel valves and then finish with the mock up and clearance checking. I have everything parts wise needed to finish this engine. I have an MSD billet distributor, a ported Victor intake, and a Demon 850 CFM carb. Since nobody wanted to purchase this engine I'm going to break in the cam on a running engine stand and then I plan to sponsor a couple local racers to flog this engine and get some data. Mark (Cutlass EFI) set me up with the cam & it will be a race fuel only engine. Here's some data sheets on the build:

Smitty this short block has been bagged in storage under my bench for the last two years. The assembler did smooth the sharp edges on the pistons before final assembly. I will dig it out real soon and do some measuring for you. The piston spec sheet sais the dome is 18CC. I find that hard to believe. I'm going to use clay to check my clearances. I was also considering making a clay casting of the dome to CC it for myself.

When I plugged in the numbers to the compression calculator I came up with 11.3:1 when using an 80CC combustion chamber. It will be 12.26:1 if I milled the heads down to 74CC. This is with a .040 gasket. I think I will need all the chamber I can get so I wasn't planning on milling.

Olds 350 High Performance short block

Back in 2004 a friend of mine wanted to build a drag car. He was fresh out of high school and worked at my shop as a clean up kid. He didn't know much about mechanicals, but he seemed eager to learn. I gave him a nice '86 Cutlass with a fresh Turbo 400 and a 12 bolt rear end. I also gave him a 1972 350 engine along with a 330 crank and some Ga BB heads. I showed him what needed to be done to port them but he didn't get too far. I finished the heads for him. I probably have close to 80 hours into them. I bought a bunch of parts for this engine and paid for all the machine work. My friend went into the military and lost interest. He came back from Iraq, got married and had two kids. The car was scrapped but I got the trans and I picked up the engine from the machine shop. I kinda lost track of how much money that I sunk into this thing, so I got out all the receipts and put together this spread sheet. The compression may be too high for pump gas, and I really think it's not going to be very streetable. My car is set up for a BB so I really have no need for this engine. The block is from 1970-1972. The crank and flexplate are original from my 1967 330. I have plenty of core heads if someone wants to purchase a complete running engine that can be arranged. For anyone who is really interested , I can e-mail all the photos taken and blue print data compiled during assembly. I will also throw in a stock oil pan, a split timing cover and an HEI distributor with low miles.

Olds 350 CI Race Engine

1972 350CI engine block core

1967 330 steel crank core

1967 Flex plate

1972 Damper

JE Pistons Custom 2300077 $680.75

Rings J100F84080-5 $100.00

Rod bearings 02-5029 $60.00

Main Bearings MS805P20 $60.00

Rod bushings 02-5029 $40.00

(2) Heavy metal slug 1”X1” $70.00

ARP rod bolt RB-200 $58.00

Freeze plug kit FP-640 $14.00

Race Cam Bearings RCB-499 $69.00

Gasket Set GS-550 $95.00

High Volume Oil Pump SP-754 $69.00

Bolt on pick up PU-3 $35.00

J&S 5 Main Halo $250.00

J&S Main Stud kit $85.00

Custom modern grind cam/ lifters $265.00

Machine Work Performed by LAM Racing Engines

Install rod bushings, Fit/ assemble rods & pistons,

final polish rod beams, Recondition rods with ARP bolts-

includes R&R bolts, machine oil relief grooves in rods,

deck block, piston height + .0001,

Balance rotating assembly, regrind crank

Rods - .020 Mains - .020, install slugs of heavy metal (mill),

Install main studs, mill for main girdle (halo) to 2.175 depth of caps

Dial bore gauge main bearing bores, low limit to middle of spec,

Final wash block and install cam bearings & freeze plugs, check main

bearing clearance and ring end gaps. Total machine shop services - $1311

Final assembly and measurement performed by Dane Lulling of

Mild to Wild Racing $400

total investment- $3825.75

So there you have it. I have decided to finish the GA heads with some Stainless steel valves and then finish with the mock up and clearance checking. I have everything parts wise needed to finish this engine. I have an MSD billet distributor, a ported Victor intake, and a Demon 850 CFM carb. Since nobody wanted to purchase this engine I'm going to break in the cam on a running engine stand and then I plan to sponsor a couple local racers to flog this engine and get some data. Mark (Cutlass EFI) set me up with the cam & it will be a race fuel only engine. Here's some data sheets on the build:

Smitty this short block has been bagged in storage under my bench for the last two years. The assembler did smooth the sharp edges on the pistons before final assembly. I will dig it out real soon and do some measuring for you. The piston spec sheet sais the dome is 18CC. I find that hard to believe. I'm going to use clay to check my clearances. I was also considering making a clay casting of the dome to CC it for myself.

When I plugged in the numbers to the compression calculator I came up with 11.3:1 when using an 80CC combustion chamber. It will be 12.26:1 if I milled the heads down to 74CC. This is with a .040 gasket. I think I will need all the chamber I can get so I wasn't planning on milling.

Greg

Last edited by rcktdoc; March 26th, 2014 at 04:11 AM.

#466

No need to remove piston. Bring piston to TDC. With an indicator on it drop piston until dome is below flush. Record distance that piston was dropped into the bore. Now you can calculate the CC of the bore for that distance. Next put a little grease in the ring gap around the piston to wall for a good seal and put your CC plat on the block and CC the remaining area. Subtract that from total volume you calculated earlier and you have an exact measurement of your dome volume.

#467

#470

But maybe you could make 800 with the same compression, just with less dome via a different head and piston configuration. If that was the best way to go don't you think other builders would still be doing it that way? Chevy, Ford, whatever? Big domes with appropriate chambers vs flat tops and smaller chambers?

You have to do it that way because of what you have to work with, my hat's off to you. But that doesn't mean it's the best way by any stretch. That was my point.

Last edited by cutlassefi; March 26th, 2014 at 12:28 PM.

#474

Best, or not it's what I'm stuck with. I do have a lot of cash tied up in this motor and it's really not doing any body any good sitting under the bench. So I say pull the pin and let's see if this rocket will fly or grenade. Thanks for your input guys - Mark, Greg, Smitty. I had thought about having the tops machined down a little. Who knows maybe I will still. The ProComps might work better with a bigger chamber. I really don't want to put any more money into this thing. Mark, Jeremy was asking what kind of vacuum this engine might have with that cam. Do you have any projections?

#475

You have to remember piston-valve clearance with any piston. Just because it doesn't hit the head......doesn't mean it clears the valves. Not all domes are created equal. That's why you send the manufacturer a mold so you get the slugs you want/need.

#477

So far no one has posted anything wrong. But some aren't taking into consideration the era of what was done and when. The ability to take a mold of the chamber and send it to Diamond, have them scan it in, run it through a combustion analysis, and design the best possible piston top for the desired compression ratio, is really not all that old of a technology. From mold to finished piston in 7-10 days now. I can remember when they put them in a CMM and probed the mold to get the chamber shape and will worked from there and it took a while. Before that they cut it close and you had to finish it to the chamber on your own. A lot has changed in just the last 5 years. Probably more change in the last 5yrs than the 15yrs before them.

#478

They can even hard coat a piston that you won't melt through on a lean N2O tune. Though something else most likely will give way. That was unheard of a couple of years ago. True N2O tuners no longer read the plug to see how much aluminum has transfered to it. They use a safe tune and go from there by the clocks & mph to know if their getting it right.

#479

Greg what ever happened to your iron Batten headed engine? That thing was a beast. It's been a while since you've posted up any progress on your race car. I know you've been real busy with restorations. The last thing I saw about your car, you were working on the frame in the back, for a mini tub. How's it looking? Do you think you'll hit the track this year? We met at Alston's when my chassis was being built.

Dave

#480

The 69 is sitting in the back of the shop. Dont think it will be out anytime soon.

Been trying to finish my 69 post 442 but trying to find the nos parts to complete has been tough, havent work on it for about 7-8 months.Still have the engine from the 69 .

Greg

Been trying to finish my 69 post 442 but trying to find the nos parts to complete has been tough, havent work on it for about 7-8 months.Still have the engine from the 69 .

Greg

, but it's not necessarily the best way.

, but it's not necessarily the best way.