Lifter bore grooves needed?

#1

Lifter bore grooves needed?

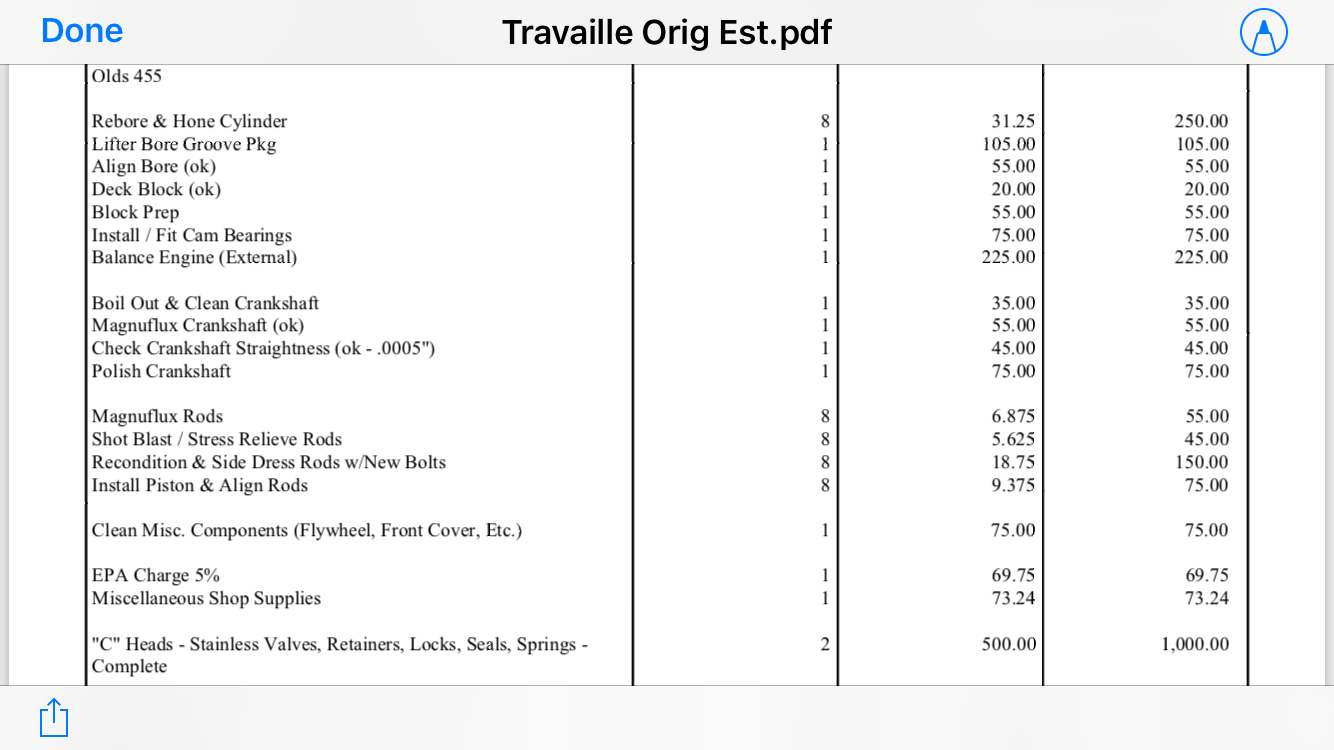

I dropped my 455 off at the engine shop a couple days ago and they sent me the cost estimate today. They are suggesting that I groove the lifter bores for $100+ . Is this nessessary? I have been doing quite a bit of research and this procedure hasnít come up.

also, the estimate for checking /machining the engine (minus the heads), and supplying all the parts including a set of used kB132 pistons is $3,300. This is with me assembling it. Does this seem like too much or does it sound about right?

thanks for any advise you guys can offer up.

also, the estimate for checking /machining the engine (minus the heads), and supplying all the parts including a set of used kB132 pistons is $3,300. This is with me assembling it. Does this seem like too much or does it sound about right?

thanks for any advise you guys can offer up.

#2

I have never heard of grooving lifter bores, so I would say it is not needed.

As for the machining costs, I have no idea where you are so there's no way to know if those are typical for the region or not.

As for the machining costs, I have no idea where you are so there's no way to know if those are typical for the region or not.

#5

I would have them explain what they are talking about better. Depending on their answer, I would maybe be looking for a new machine shop. Lots more bad machine shops out there than good ones. At least in my area it is that way.

#6

Grooving the lifter bores to aid oiling of cam lobes is not unheard of. If it is necessary or not is open for speculation.

https://www.summitracing.com/search/...grooving-tools

https://www.summitracing.com/search/...grooving-tools

#8

well I would have done it at a place I know of locally but this shop (which is 1.5 hours away) is the only place I could find that has torque plates for the olds engines. The guy at the local shop I usually go to actually called around to see if he could find another shop in the area that had any olds torque plates but couldnít find any either.

#10

well I would have done it at a place I know of locally but this shop (which is 1.5 hours away) is the only place I could find that has torque plates for the olds engines. The guy at the local shop I usually go to actually called around to see if he could find another shop in the area that had any olds torque plates but couldnít find any either.

#12

I didn't see balancing the rotating assembly on the list.

I think my shop charged me $2,300 including the Wiseco pistons. That was for hot tank, boring, decking, line-honing, new freeze plugs, rod recon, assembling pistons, polishing the crank, and balancing. No head work or other parts included.

Good luck with the build!

I think my shop charged me $2,300 including the Wiseco pistons. That was for hot tank, boring, decking, line-honing, new freeze plugs, rod recon, assembling pistons, polishing the crank, and balancing. No head work or other parts included.

Good luck with the build!

#13

I didn't see balancing the rotating assembly on the list.

I think my shop charged me $2,300 including the Wiseco pistons. That was for hot tank, boring, decking, line-honing, new freeze plugs, rod recon, assembling pistons, polishing the crank, and balancing. No head work or other parts included.

Good luck with the build!

I think my shop charged me $2,300 including the Wiseco pistons. That was for hot tank, boring, decking, line-honing, new freeze plugs, rod recon, assembling pistons, polishing the crank, and balancing. No head work or other parts included.

Good luck with the build!

#18

The engine guy is saying that the stock head and main bolts should be strong enough for this build. This is interesting to me because it seems that Iíve seen a lot of ppl online using ARP bolts. Do I need them?

He did recommend using arp rod bolts though. I told him I prob didnít want them. I read in Bill Trovatos book that they arenít needed because the factory ones are usually strong enough. How bout dat?

He did recommend using arp rod bolts though. I told him I prob didnít want them. I read in Bill Trovatos book that they arenít needed because the factory ones are usually strong enough. How bout dat?

#19

#20

rod bolts

if you are using all stock bolts everywhere else

go with the OEM rod bolts. The recondition job should include them being checked good for bend and stretch. If they are up to code Buy a set of new rod nuts and install as directed (ARP Lube)

if you are using all stock bolts everywhere else

go with the OEM rod bolts. The recondition job should include them being checked good for bend and stretch. If they are up to code Buy a set of new rod nuts and install as directed (ARP Lube)

Thread

Thread Starter

Forum

Replies

Last Post