Main Cap Question

#1

Main Cap Question

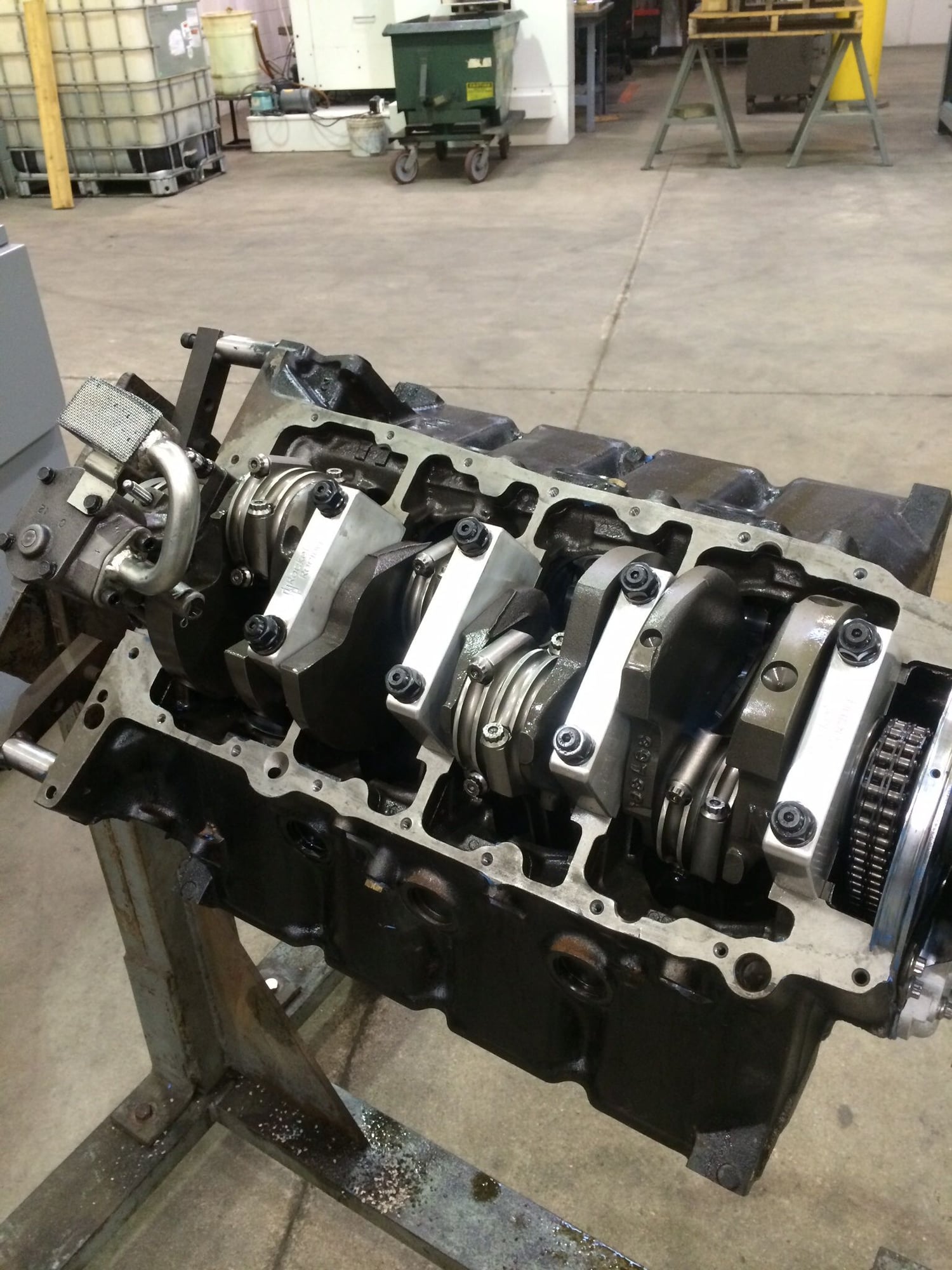

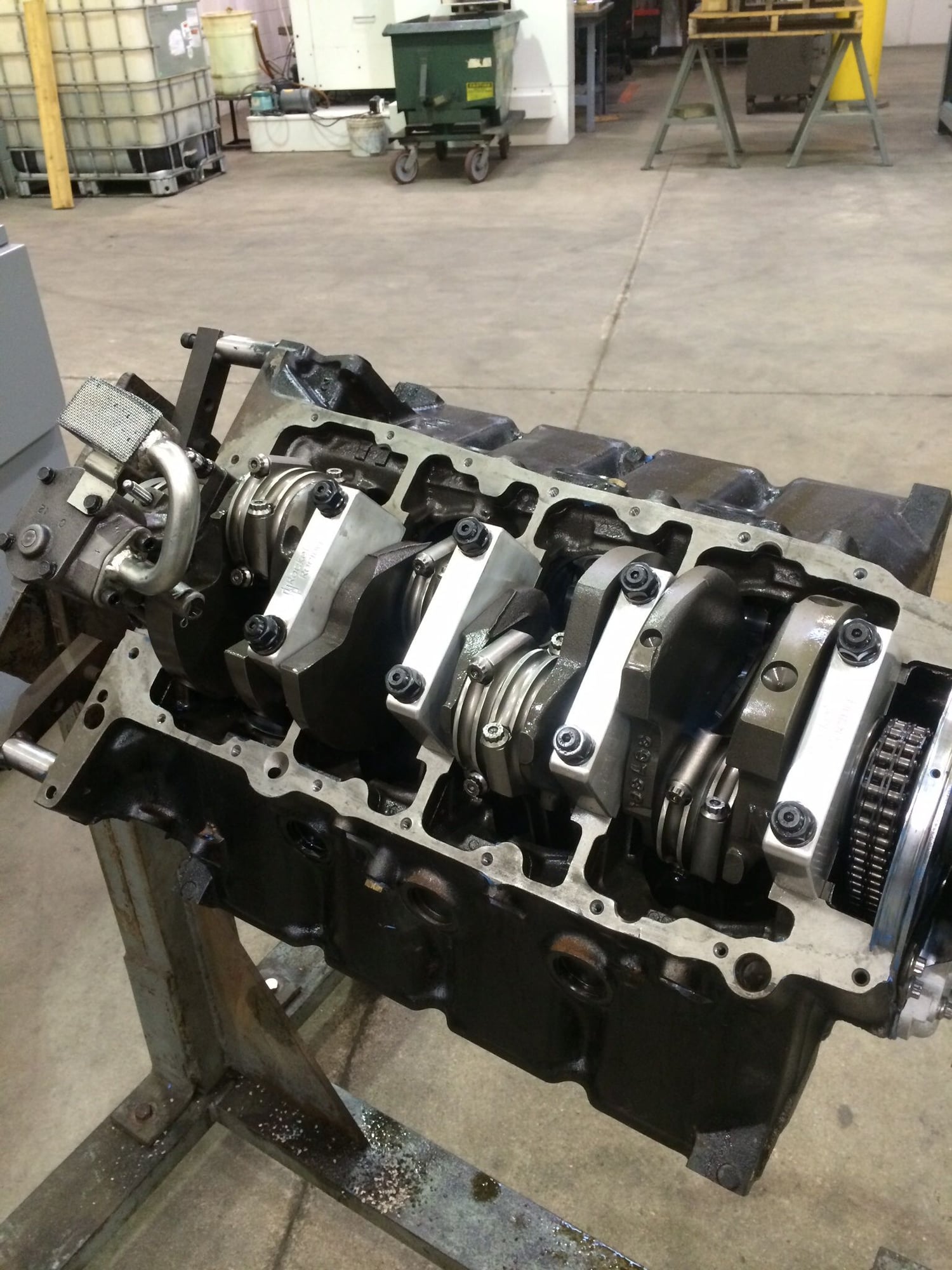

Hello! I have a Main Cap question. I am slowly (and I mean slowly) working on an Olds 496 build. I have a 1974 455 block I’m working with. I’m putting a lot of decent, if not nice parts on this motor (could be better/could be worse). I have ported Edelbrock heads/intake, Holley Ultra HP 850 Carb, MSD ignition, American Racing Headers, Eagle 4.500 crankshaft and Eagle H-Beam rods with L19 bolts, etc.…

I recently purchased a Rocket Racing chrome moley full main girdle to support the bottom end. I planned on getting billet aluminum Main Caps to replace the cast iron originals. I was talking to a friend and he asked why I would go with Aluminum vs Steel. He said (in his opinion) that steel caps would be better than aluminum. His thoughts were that aluminum caps would dissipate heat better over a short period of time (drag racing) but steel would be better/stronger for everything else. He said something about the aluminum caps expanding, which would cause problems with a full girdle. I’m not an engine builder, so I don’t pretend to know about all this stuff. My buddy is a dirt track/circle track racer. I figured I would ask the Olds experts. Would you recommend aluminum caps or a billet steel? And, if billet steel, who sells them?

I am building my Olds 442 to be 50/50 street & track. No long highway trips. All street driving will be city (small town)/secondary highway driving at best. The rest will be at the race track (St Louis Gateway - Ľ mile) that is about 15 minutes frommy house.

Thanks for your time

Ray

I recently purchased a Rocket Racing chrome moley full main girdle to support the bottom end. I planned on getting billet aluminum Main Caps to replace the cast iron originals. I was talking to a friend and he asked why I would go with Aluminum vs Steel. He said (in his opinion) that steel caps would be better than aluminum. His thoughts were that aluminum caps would dissipate heat better over a short period of time (drag racing) but steel would be better/stronger for everything else. He said something about the aluminum caps expanding, which would cause problems with a full girdle. I’m not an engine builder, so I don’t pretend to know about all this stuff. My buddy is a dirt track/circle track racer. I figured I would ask the Olds experts. Would you recommend aluminum caps or a billet steel? And, if billet steel, who sells them?

I am building my Olds 442 to be 50/50 street & track. No long highway trips. All street driving will be city (small town)/secondary highway driving at best. The rest will be at the race track (St Louis Gateway - Ľ mile) that is about 15 minutes frommy house.

Thanks for your time

Ray

#2

Steel inherently has three times the stiffness of aluminum. Most aluminum blocks use steel caps. Aluminum caps negate the whole point of a girdle. Frankly, even the stock caps would be a better choice in my opinion. The problem with the Olds bottom end isn't strength of the caps, it's stiffness. As the caps deflect, you lose the oil film on the bearings, leading to bearing failure.

#3

How much power do you expect to make?

I made 600+ with stock caps and a J&S 5 main halo. Crank was internally balanced and hardened though. I would recommend at least doing it internal as well.

I made 600+ with stock caps and a J&S 5 main halo. Crank was internally balanced and hardened though. I would recommend at least doing it internal as well.

#4

Whats the advantage of balancing internally ? Who is qualified to harden a 455 crank ?

Ralph

#5

Ohio crank did the crank on this build. They did a good job but I’m not sure the hardening was necessary. Throughout multiple dyno pulls, oil pressure remained consistent.

#6

The alum caps are thicker than stock.

This is suppose to eliminate the flexing and or squirm.(ARP bolts also)

They are also suppose to help with harmonics.

These caps need to be line bored with the block.

To use a girdle you would need to machine down the height

which would defeat the design I believe.

I am running Alum caps, 500 + engine hp w/ 125 shot Nos

3 years of beating on it , no issues.

#7

The ARP studs are STRONGER than stock bolts. They are not STIFFER, however. The studs will stretch the same number of micro-inches per inch for a given load as the stock bolts. The only difference is that the stock bolts will break first if you continue to load them.

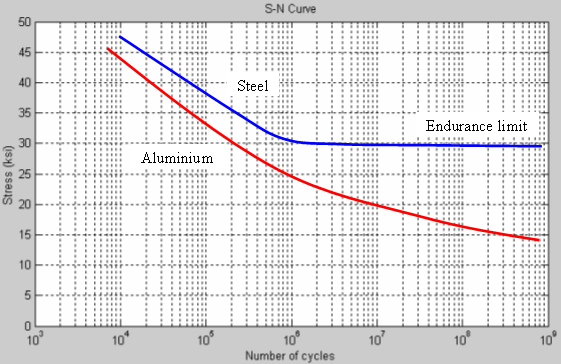

The more important issue in an engine is fatigue loading. This is called the S-N curve for the material. The endurance limit is the number of cycles a metallic part can sustain before the part sees a fatigue failure. Steel actually work hardens and eventually bottoms out on the S-N curve. Aluminum continues to lose strength with cyclical loading.

This is why aluminum con rods need to be checked and replaced periodically. Sorry, but as a structural engineer I can see no reason to use aluminum main caps (or girdles).

#8

Joe,

Being a structural engineer

I assume you know Steel & Alum come in several grades, tensiles and yields.

The caps are made 7075 T73 heat treated alum.

and much stronger than cast iron.

They are also taller (thicker) in the direction of crank force than cast iron.

Hands down better than stock cast.

This is for caps not rods.

To each there own.

Good luck.

Being a structural engineer

I assume you know Steel & Alum come in several grades, tensiles and yields.

The caps are made 7075 T73 heat treated alum.

and much stronger than cast iron.

They are also taller (thicker) in the direction of crank force than cast iron.

Hands down better than stock cast.

This is for caps not rods.

To each there own.

Good luck.

#9

Joe,

Being a structural engineer

I assume you know Steel & Alum come in several grades, tensiles and yields.

The caps are made 7075 T73 heat treated alum.

and much stronger than cast iron.

They are also taller (thicker) in the direction of crank force than cast iron.

Hands down better than stock cast.

This is for caps not rods.

To each there own.

Good luck.

Being a structural engineer

I assume you know Steel & Alum come in several grades, tensiles and yields.

The caps are made 7075 T73 heat treated alum.

and much stronger than cast iron.

They are also taller (thicker) in the direction of crank force than cast iron.

Hands down better than stock cast.

This is for caps not rods.

To each there own.

Good luck.

Heat treating aluminum (or steel, or most metals) improves STRENGTH. It has zero effect on STIFFNESS. 7075-T73 has virtually the same modulus (the inherent stiffness properties) as does dead soft aluminum. Main caps don't usually fail due to a strength issue, they fail due to either fatigue loading or deflections. The deflections are what cause bearings to go bad, as this lets the oil film leak out and thus wipes bearings. And obviously we are talking about main caps. My con rod comment was an example of how aluminum engine parts require more frequent inspection and replacement due to fatigue loading.

#10

I am NOT a structural engineer so my opinion don't really matter here but... I did not know and can't understand why they made main caps out of aluminum. If they need to be better then make them out of steal to the specs of those aluminum ones. In this area of the engine are they really that concerned with saving 4 or 5 lbs.

#11

I am NOT a structural engineer so my opinion don't really matter here but... I did not know and can't understand why they made main caps out of aluminum. If they need to be better then make them out of steal to the specs of those aluminum ones. In this area of the engine are they really that concerned with saving 4 or 5 lbs.

The bottom line is that there is a lot of "conventional wisdom" that isn't very wise. One of the classics for me was the use of those stupid straps across the factory main caps. Sorry, but structurally that's just worthless.

If the straps were actually added parent metal on the main caps, that would be beneficial, but separate straps like this with clearance holes to the bolts don't pick up any load at all, and the stiffness increase is barely measurable.

#12

I am NOT a structural engineer so my opinion don't really matter here but... I did not know and can't understand why they made main caps out of aluminum. If they need to be better then make them out of steal to the specs of those aluminum ones. In this area of the engine are they really that concerned with saving 4 or 5 lbs.

Jensen, I totally agree.

#13

I agree with Joe in theory!

But their have been many that have used aluminum main caps with out failure.

This topic has been discussed on ROP you might want to look it up for more feedback on the subject.

But their have been many that have used aluminum main caps with out failure.

This topic has been discussed on ROP you might want to look it up for more feedback on the subject.

#14

#15

The one racer running aluminum 4 bolt main caps by Dave Smith is close to the top of NA Oldsmobile fastest list.

One respected engine builder said that the way the aluminum absorbs force was one reason they were using aluminum caps.

Joe I don't disagree with you on the rigidity that a steal cap offers.

I do not know how many are running cast caps with success.

One respected engine builder said that the way the aluminum absorbs force was one reason they were using aluminum caps.

Joe I don't disagree with you on the rigidity that a steal cap offers.

I do not know how many are running cast caps with success.

#16

As I've noted previously, the most important aspect here is keeping the main bearings round to protect the oil film. Once the caps deflect, bearings loose shape and the hydrostatic film goes away, followed by the crank. If you are talking about a race engine that gets torn down and inspected (and bearings replaced) frequently, then this may be a non-issue. If you want the motor to last any length of time, I'd pick the more rigid material.

#17

Whoever said this is not an engineer. Ironically, iron and steel have higher damping than aluminum. Of course, in both cases, the damping of the metal is negligible. When we need a material that damps out unwanted vibrations in aerospace applications, we often use magnesium. As an example, most fixtures for mounting a spacecraft to a vibration table are made from mag to avoid introducing any "ringing" into the test from the fixturing.

As I've noted previously, the most important aspect here is keeping the main bearings round to protect the oil film. Once the caps deflect, bearings loose shape and the hydrostatic film goes away, followed by the crank. If you are talking about a race engine that gets torn down and inspected (and bearings replaced) frequently, then this may be a non-issue. If you want the motor to last any length of time, I'd pick the more rigid material.

As I've noted previously, the most important aspect here is keeping the main bearings round to protect the oil film. Once the caps deflect, bearings loose shape and the hydrostatic film goes away, followed by the crank. If you are talking about a race engine that gets torn down and inspected (and bearings replaced) frequently, then this may be a non-issue. If you want the motor to last any length of time, I'd pick the more rigid material.

#20

I’m definitely not an engineer so I wouldn’t think to argue with you Joe and what you say does make sense. I love the whole deer whistle thing!

So, that said, do we Olds guys have a hole in the market? I mean, I know we inherently have a hole in the market just because it’s Oldsmobile and we don’t have a big aftermarket presence. But, the only main caps I know of are the original iron caps that are all 40+ years old or billet aluminum caps. It would seem that if someone developed a billet steel main cap with the same dimensions as the billet aluminum ones, they would be able to corner the market.

So, that said, do we Olds guys have a hole in the market? I mean, I know we inherently have a hole in the market just because it’s Oldsmobile and we don’t have a big aftermarket presence. But, the only main caps I know of are the original iron caps that are all 40+ years old or billet aluminum caps. It would seem that if someone developed a billet steel main cap with the same dimensions as the billet aluminum ones, they would be able to corner the market.

#21

Both Rocket Racing and Dick Miller offer steel caps.

But the concern is the spreading of the block between the main saddles and the pan rails. Billet caps of any sort won’t help that. That’s why many opt for the halo, or even a full pan rail girdle, right or wrong.

But the concern is the spreading of the block between the main saddles and the pan rails. Billet caps of any sort won’t help that. That’s why many opt for the halo, or even a full pan rail girdle, right or wrong.

#22

Yea Cutlassefi, I see what your saying, thanks! I cannot find them on Rocket Racing, but I'm in contact with Dick Miller. It looks like his are 1045 medium carbon steel.

So, if this is the case, would a good combination be the Rocket Racing chrome moly full main girdle, Dick Miller 1045 steel main caps with ARP studs? To me, this sounds likea pretty solid bottom end, but I’m no expert by any stretch.

So, if this is the case, would a good combination be the Rocket Racing chrome moly full main girdle, Dick Miller 1045 steel main caps with ARP studs? To me, this sounds likea pretty solid bottom end, but I’m no expert by any stretch.

#23

I’m definitely not an engineer so I wouldn’t think to argue with you Joe and what you say does make sense. I love the whole deer whistle thing!

So, that said, do we Olds guys have a hole in the market? I mean, I know we inherently have a hole in the market just because it’s Oldsmobile and we don’t have a big aftermarket presence. But, the only main caps I know of are the original iron caps that are all 40+ years old or billet aluminum caps. It would seem that if someone developed a billet steel main cap with the same dimensions as the billet aluminum ones, they would be able to corner the market.

So, that said, do we Olds guys have a hole in the market? I mean, I know we inherently have a hole in the market just because it’s Oldsmobile and we don’t have a big aftermarket presence. But, the only main caps I know of are the original iron caps that are all 40+ years old or billet aluminum caps. It would seem that if someone developed a billet steel main cap with the same dimensions as the billet aluminum ones, they would be able to corner the market.

Most that are making serious power are going with the new Rocket racing big block or Nascar or DX block small block.

#25

The alum caps are thicker than stock.

This is suppose to eliminate the flexing and or squirm.(ARP bolts also)

They are also suppose to help with harmonics.

These caps need to be line bored with the block.

To use a girdle you would need to machine down the height

which would defeat the design I believe.

I am running Alum caps, 500 + engine hp w/ 125 shot Nos

3 years of beating on it , no issues.

What brand of oil pump is that?

#26

Bernhard, I agree, I would love to have one of those Rocket Racing blocks! But, they cost $5000.

I got a 455 block for $700 that was vatted, bored and honed .060 over and decked. I purchased a Rocket Racing full main girdle for $1000 (with oil pan studs and RR 2 piece timing chain cover) and can get the steel main caps with ARP main studs from Dick Miller for about $500.

So, basically $2200 vs $5000. And of course, I purchased the block long before the new Rocket Racing block came out. While I fully admit that the new RR block is the superior option, and something I may pursue in the distant future, the girdle and caps are what I'm looking at right now. Had I known 2 years ago, when I bought the 455 block (and I wish I did!) that Rocket Racing was going to come out with this new block, I may have went in a different direction.

I got a 455 block for $700 that was vatted, bored and honed .060 over and decked. I purchased a Rocket Racing full main girdle for $1000 (with oil pan studs and RR 2 piece timing chain cover) and can get the steel main caps with ARP main studs from Dick Miller for about $500.

So, basically $2200 vs $5000. And of course, I purchased the block long before the new Rocket Racing block came out. While I fully admit that the new RR block is the superior option, and something I may pursue in the distant future, the girdle and caps are what I'm looking at right now. Had I known 2 years ago, when I bought the 455 block (and I wish I did!) that Rocket Racing was going to come out with this new block, I may have went in a different direction.

Last edited by 1970Olds442; January 6th, 2018 at 09:59 PM.

#28

Yea Cutlassefi, I see what your saying, thanks! I cannot find them on Rocket Racing, but I'm in contact with Dick Miller. It looks like his are 1045 medium carbon steel.

So, if this is the case, would a good combination be the Rocket Racing chrome moly full main girdle, Dick Miller 1045 steel main caps with ARP studs? To me, this sounds likea pretty solid bottom end, but I’m no expert by any stretch.

So, if this is the case, would a good combination be the Rocket Racing chrome moly full main girdle, Dick Miller 1045 steel main caps with ARP studs? To me, this sounds likea pretty solid bottom end, but I’m no expert by any stretch.

#29

Again, this is a stiffness design problem, not a strength problem. Since the space is limited, steel would be the correct design choice. The real trick is retrofitting some sort of support (girdle, or whatever) that actually carries load. The amount of deflection we're talking about is very small, and any clearance in the bolt holes means that the fasteners just move in the holes before the girdle becomes useful. Match drilled, press fit pins or a similar fastening feature would be required for the added system to actually be useful. We deal with design problems like this in the aerospace world all the time, only there weight does matter.

#30

^^^THIS!

Again, this is a stiffness design problem, not a strength problem. Since the space is limited, steel would be the correct design choice. The real trick is retrofitting some sort of support (girdle, or whatever) that actually carries load. The amount of deflection we're talking about is very small, and any clearance in the bolt holes means that the fasteners just move in the holes before the girdle becomes useful. Match drilled, press fit pins or a similar fastening feature would be required for the added system to actually be useful. We deal with design problems like this in the aerospace world all the time, only there weight does matter.

Again, this is a stiffness design problem, not a strength problem. Since the space is limited, steel would be the correct design choice. The real trick is retrofitting some sort of support (girdle, or whatever) that actually carries load. The amount of deflection we're talking about is very small, and any clearance in the bolt holes means that the fasteners just move in the holes before the girdle becomes useful. Match drilled, press fit pins or a similar fastening feature would be required for the added system to actually be useful. We deal with design problems like this in the aerospace world all the time, only there weight does matter.

All other girdles use clamping force to aide bottom end support.

So is the stiff crank and light rotating assembly the reason these engines live?

What effect does stroke and road length have on forces being applied to the block.

The reason I ask is because the the early 425/400 have shorter stroke and longer rods.

I was wondering if this lessons the load compaired to the later 455/400

longer stroke and shorter rod engines?

#31

I know BTR offers Billet Steal caps! I have a set of used BTR steel caps I’ll use for a future build. I probably should have had a set installed on the build Mark did for me but we shall see if anything happens in the future!

#32

Pro-Gram Engineering used to make Olds main caps also. Not sure if they do anymore. Here a link with some tech info. http://www.pro-gram.com/tech.html

#33

Pro-Gram Engineering used to make Olds main caps also. Not sure if they do anymore. Here a link with some tech info. http://www.pro-gram.com/tech.html

Here is a mildly technical discussion of strength vs. stiffness vs. hardness of metals.

#34

I know my information was lacking and wasn't meant to show anything but support for your information Joe. I didn't mention it but you pointed it out that the expansion rate is huge for aluminum compared to steels, cast or otherwise.

Bearing clearances would be my concern also.

Bearing clearances would be my concern also.

Thread

Thread Starter

Forum

Replies

Last Post

Al2011

Big Blocks

6

November 20th, 2013 07:15 AM