Help no spark at the ignition coil

#4

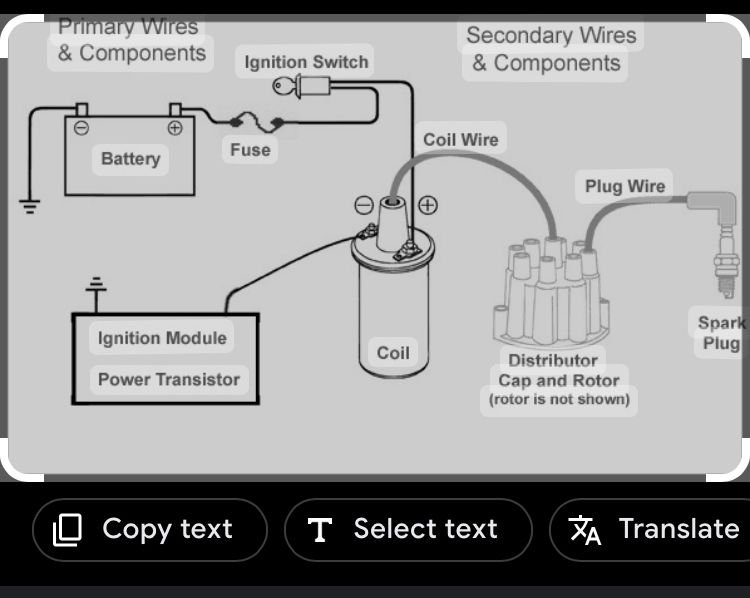

As fleming442 noted, check for voltage going "into" the IGN coil. You must have voltage going in before you can have voltage coming out. If you have voltage going into the IGN coil check the IGN coil itself.

Measure both the primary winding resistance and the secondary winding resistance of the IGN coil.

Take the several minutes to read this >>> Electrical advice please.

Measure both the primary winding resistance and the secondary winding resistance of the IGN coil.

Take the several minutes to read this >>> Electrical advice please.

#6

My 63 died one time in traffic. We pushed it to a side street. As I'm standing there scratching my head, this old dude on his porch asked if I had "power to the points". I was (still am) pretty clueless about points, so the old dude walked me through pushing the contact in and checking for arcing across the contacts. The problem was actually that the coil wire had wiggled up out of the cap. Pushed it down, and away we went.

#7

#10

#11

Yes, it was the OP's 64 98. Sorry I didn't put an explanation when I moved the first 2 posts. You can blame Oldsguy. He's visiting and was bothering me this morning when I should have been doing more important things.

#13

https://classicoldsmobile.com/forums...gnition-76706/

#14

Ok yes itís stock Iíll send pic

But first off thank you this made my weekend

whew . Still no luck with spark , but man thank God for this forum. Iíll have to reread some of electrical advice thread . In order to check coil ( its new ) I was looking at old coil thereís a terminal still attached, looks like I pulled wire from idk 🤷🏻♂️

whew . Still no luck with spark , but man thank God for this forum. Iíll have to reread some of electrical advice thread . In order to check coil ( its new ) I was looking at old coil thereís a terminal still attached, looks like I pulled wire from idk 🤷🏻♂️

#18

Do you have a test meter (Digital Multimeter) to measure voltage & resistance (Ohms)? Your first order of business is to measure the voltage at the positive (+) terminal of the ignition coil. Do you have ~12V at that terminal? You must have an input voltage at the positive (+) terminal of the ignition coil. Whether your coil is new or old, you're DOA if you can't provide an input voltage at the (+) terminal.

#21

#22

Is there power at the + terminal of the coil with the key in RUN and START positions? Does the - terminal of the coil alternate between closed and open to ground with the engine cranking?

#24

Disconnect the wire at the "-" terminal on the coil. Check continuity from that wire to ground as the engine turns over. You should see open circuit when the point are on the high part of the distributor cam and continuity when the points are closed. If not, figure out why.

#25

That is not how it's wired if it is stock. Instead of measuring continuity, pull the high voltage lead off the top of the coil to prevent starting, hook a test light to the coil negative terminal. Crank the engine with the key and see if the test light blinks on and off.

#26

That is not how it's wired if it is stock. Instead of measuring continuity, pull the high voltage lead off the top of the coil to prevent starting, hook a test light to the coil negative terminal. Crank the engine with the key and see if the test light blinks on and off.

#27

I understand how points work, show me where the fuse is for the igniton. In simplest terms yes that is a typical ignition system without those pesky items like the resistance wire and the bypass wire.

#28

I'm not talking about the power side of the circuit. I'm a big fan of testing at the lowest level possible. The method I suggested only tests the points and the wire to the coil, period. Bad or improperly adjusted points are a high probability cause of ignition problems.

#30

I'm not talking about the power side of the circuit. I'm a big fan of testing at the lowest level possible. The method I suggested only tests the points and the wire to the coil, period. Bad or improperly adjusted points are a high probability cause of ignition problems.

#34

Test coil:

(1) Remove all wires from coil

(2) Measure resistance (Ohms) of primary winding in coil. Attach one DMM probe to (-) terminal on coil attach other probe to (+) coil terminal. Reading must fall below 2.0 Ohms.

(3) Measure resistance of secondary winding. All wires disconnect from coil. Place one DMM probe on coil (+) terminal and other probe inside the top (center) tower where the coil wire would be attached. Set Ohm scale to 20K. Resistance must be greater then 6K, optimally greater than 13K+ Ohms.

(1) Remove all wires from coil

(2) Measure resistance (Ohms) of primary winding in coil. Attach one DMM probe to (-) terminal on coil attach other probe to (+) coil terminal. Reading must fall below 2.0 Ohms.

(3) Measure resistance of secondary winding. All wires disconnect from coil. Place one DMM probe on coil (+) terminal and other probe inside the top (center) tower where the coil wire would be attached. Set Ohm scale to 20K. Resistance must be greater then 6K, optimally greater than 13K+ Ohms.

#36

You indicated the test light flashes therefore points are opening and closing. Testing coil primary & secondary winding demonstrates if enough voltage can be delivered. This is not to say the points are not adjusted correctly or there is a different issue.

#37

If it's flashing when turning over then you have power to the coil and the points are opening and closing. If at this point you have no spark chances are good that your coil is not working. One more test, connect the high voltage wire back up and attach a timing light to that wire and see if it flashes. If it does, then either your timing is off or your not getting fuel.