Replacing front drums

#1

Replacing front drums

The front drums on my '72 Cutlass are at discard diameter and need to be replaced. I have a few questions:

- Hub removal - the service manual says to drill a 5/8" hole 1/4" deep into the hub bolt heads (wheel studs). Is this the best way to do it?

- Hub installation - the service manual says to "press new bolt into the hub", and the picture shows using a press. I don't have a press. Is this something I can do myself or do I need to take it to somewhere to have it done with a press?

- Source for new drums - there aren't a lot of options available for front drums. I can't find any that look the same as stock, but maybe it doesn't matter. Some have different cooling fins and some have more than 5 holes for studs. Any recommendations on what to use or what to look for?

#2

The front drums on my '72 Cutlass are at discard diameter and need to be replaced. I have a few questions:

- Hub removal - the service manual says to drill a 5/8" hole 1/4" deep into the hub bolt heads (wheel studs). Is this the best way to do it?

- Hub installation - the service manual says to "press new bolt into the hub", and the picture shows using a press. I don't have a press. Is this something I can do myself or do I need to take it to somewhere to have it done with a press?

- Source for new drums - there aren't a lot of options available for front drums. I can't find any that look the same as stock, but maybe it doesn't matter. Some have different cooling fins and some have more than 5 holes for studs. Any recommendations on what to use or what to look for?

#4

The studs need to each be pressed out first, otherwise the hub won't separate cleanly from the drum. Too many have tired this brute force approach and been back looking for replacement parts.

#5

Thanks for the replies guys!

- I understand that the studs are swaged to the hub. How tight is the stud to the drum? Is it similarly swaged, slight interference fit, or a slide fit?

- When driving new studs into the hub I assume they are first fully driven into the hub alone (with support on the back side), and then the drum is slid or driven over the studs to mate with the hub?

- Does applying heat to the hub and/or cold to the studs help with installing the studs in the hub?

#6

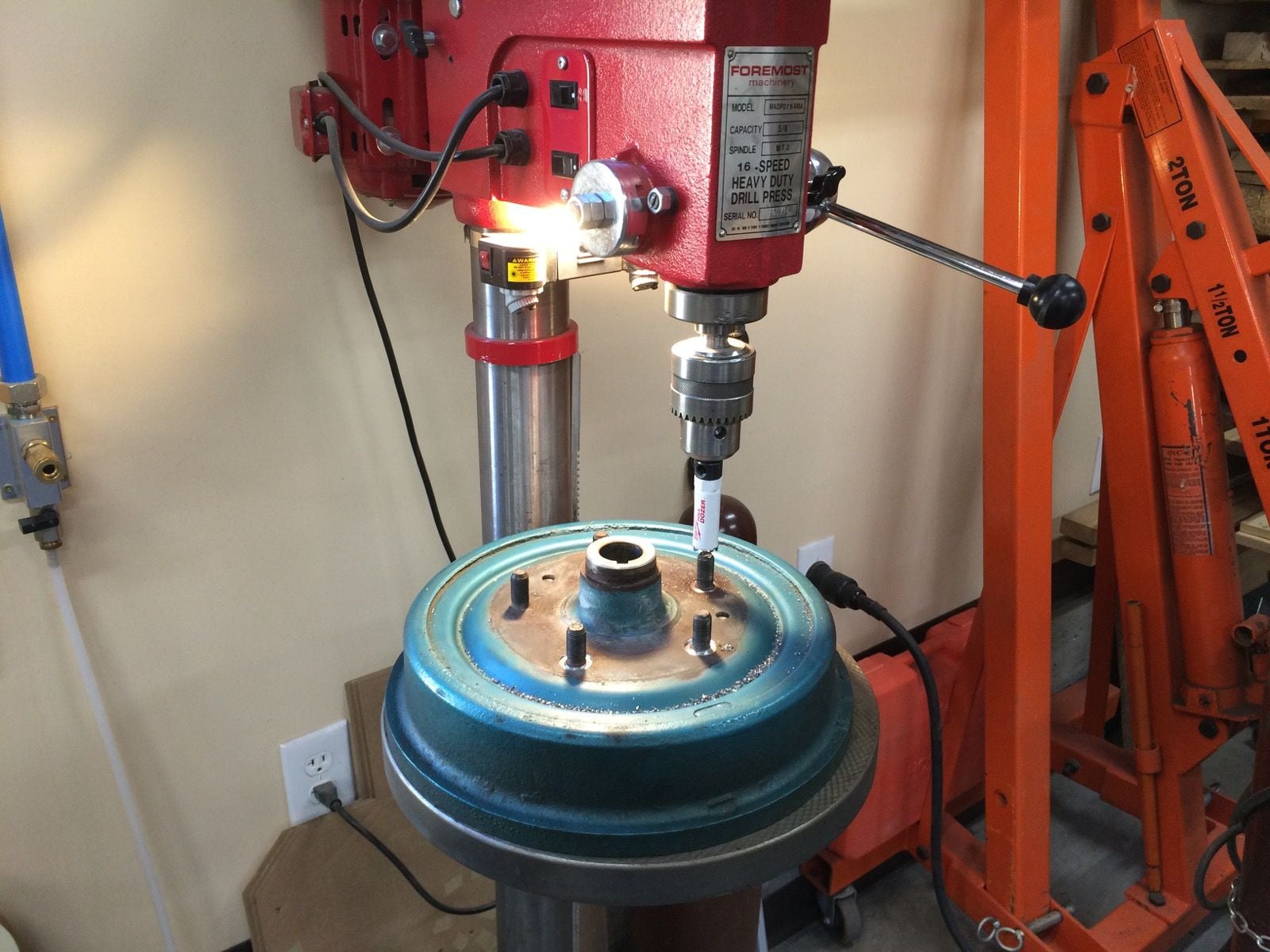

The swage cutter looks like this.

People have used holesaws.

When driving new studs into the hub I assume they are first fully driven into the hub alone (with support on the back side), and then the drum is slid or driven over the studs to mate with the hub?

#7

Yikes. I’m 0-for-2 on the prior post. Let me take another swing at it:

Option A) You first cut through the swaged portion of the stud that’s inside the drum (per Joe’s excellent photo) using a $105 cutting tool (!) or maybe a hole saw. That should allow the drum to be removed and the remaining splined section of the stud can be driven out of the hub from front to back.

Option B) Drill out or mill the head of the stud and press/drive it out from back to front. If you try to press/drive it out from front to back then you shove the enlarged swaged section of the stud through the smaller hub opening, possibly resulting in oversized hub holes.

When installing the new studs, how do you replicate the swaged fitment of the stud in the drum?

Option A) You first cut through the swaged portion of the stud that’s inside the drum (per Joe’s excellent photo) using a $105 cutting tool (!) or maybe a hole saw. That should allow the drum to be removed and the remaining splined section of the stud can be driven out of the hub from front to back.

Option B) Drill out or mill the head of the stud and press/drive it out from back to front. If you try to press/drive it out from front to back then you shove the enlarged swaged section of the stud through the smaller hub opening, possibly resulting in oversized hub holes.

When installing the new studs, how do you replicate the swaged fitment of the stud in the drum?

#8

There is available a swaging tool that fits over the stud and the shop press does the work. Sorry, I don't have a pic of that tool; you can probably find it with a Google search. Most auto parts stores had those tools and used them frequently to replace worn out drums or broken studs. Don't know if they still do that. Remember that A body cars generally had 7/16" studs and thus require that size tools. Then after the new drum is installed it may need truing on a brake drum lathe which is hard to find these days. Good luck!

#9

This project is moving slooow. I now have the hubs and drums separated and am trying to source new drums. I can confirm that a 5/8" Milwaukee HoleDozer will neatly cut the swage from a drum allowing the stud to be removed from the hub. But, be sure to use cutting oil. After a single cut without oil my first bit was toast (rookie move). Using cutting oil I was able to make 5 cuts with a new bit and it was still going strong. Maybe my first bit was defective, but I swear by cutting oil now. I also tried drilling out the heads of a couple of studs from the back side but found that to be way more of a hassle than the hole saw with oil. YMMV.

My questions:

- What are the pros and cons of using drums with swaged studs versus "loose" drums where the studs are held in by speednuts. Both styles are available in the aftermarket. I'd prefer to use the loose style if it means I don't have to find a shop to do the swaging.

- How important is it to true the assembly on a brake drum lathe?

My questions:

- What are the pros and cons of using drums with swaged studs versus "loose" drums where the studs are held in by speednuts. Both styles are available in the aftermarket. I'd prefer to use the loose style if it means I don't have to find a shop to do the swaging.

- How important is it to true the assembly on a brake drum lathe?

#10

- What are the pros and cons of using drums with swaged studs versus "loose" drums where the studs are held in by speednuts. Both styles are available in the aftermarket. I'd prefer to use the loose style if it means I don't have to find a shop to do the swaging.

- How important is it to true the assembly on a brake drum lathe?

- How important is it to true the assembly on a brake drum lathe?

If you are swaging the drum to the hub, have it trued so that any distortion is taken out. If using the slip on drums, be sure the mating surfaces are clean and rust-free so the drum sits flat.

Thread

Thread Starter

Forum

Replies

Last Post