Belt Squeal...

#1

Belt Squeal...

Yup. Another "belt squeal" problem, but this one's actually different and not what you think it is.

Background:

I picked up a 1989 Cadillac Brougham with an Olds 307 in it cheap. Guy I bought it from couldn't get it to run right as it "sounded like it needs fuel injector work" as the description in his ad. His story to me was that he bought the car from an older lady in town after it had sat under a tree in her yard for 10-15 years after her husband died (seats aren't toasty and the oil change sticker from 2004 shows only 61k miles, only 2000 miles since then). He bought it for cheap, drove it home, and started enjoying it. As cars that sit tend to do, it started having leaks. The one that gave him fits was the water pump started leaking and knocking, so he changed it. Put it all back together and the engine runs rough and "needs fuel injectors." He couldn't afford a shop bill on that job (it was something crazy expensive) so it's sat in his driveway for a year. I come along and get it jump started and it actually runs decently and transmission shifts fine, but the belts squeal like crazy.

So the alternator belt is rubbing all over the power steering pump because the pump isn't properly aligned. Typical problem, I presume he forgot the spacers (I found one under the car when I towed it home). I disassembled the driver's side accessory drive system and cleaned everything up, finding that he did in fact leave out the rear spacer and bolt on the lower power steering pump bracket in addition to the pump housing spacer. I go to install the rear bolt last night and... the hole in the block isn't threaded? It's also not very deep (maybe 1/4"). Inspect with a mirror and light and it appears that someone busted the bolt off inside the block... and it's recessed in there. So the guy or a shop he had it looked at screwed something up and couldn't figure out what they did wrong. Every other bolt came out perfectly fine by the way, this isn't the rust belt so nothing is corroded.

Either way, something is wrong with that hole and a 7/16-14 screw won't go in. So now here I am. Surely I'm not the only one this has ever happened to. Do I have any options other than pulling the wheel well and drilling the remains out and praying I can get the threads to hold up\helicoil? Is there a way I can rig\fabricate something to hold the rear bracket and spacer properly by attaching it to the motor mount that's nearby (and has a thin bracket itself running over to the area)? Because drilling and tapping in that area is going to suck and I would really like to avoid it if possible.

Or just find another engine (307\350) and swap it in place? Seems like a lot of work for one broken off bolt...

Yes, I do know pictures would help. I'll add them when I get home later.

Background:

I picked up a 1989 Cadillac Brougham with an Olds 307 in it cheap. Guy I bought it from couldn't get it to run right as it "sounded like it needs fuel injector work" as the description in his ad. His story to me was that he bought the car from an older lady in town after it had sat under a tree in her yard for 10-15 years after her husband died (seats aren't toasty and the oil change sticker from 2004 shows only 61k miles, only 2000 miles since then). He bought it for cheap, drove it home, and started enjoying it. As cars that sit tend to do, it started having leaks. The one that gave him fits was the water pump started leaking and knocking, so he changed it. Put it all back together and the engine runs rough and "needs fuel injectors." He couldn't afford a shop bill on that job (it was something crazy expensive) so it's sat in his driveway for a year. I come along and get it jump started and it actually runs decently and transmission shifts fine, but the belts squeal like crazy.

So the alternator belt is rubbing all over the power steering pump because the pump isn't properly aligned. Typical problem, I presume he forgot the spacers (I found one under the car when I towed it home). I disassembled the driver's side accessory drive system and cleaned everything up, finding that he did in fact leave out the rear spacer and bolt on the lower power steering pump bracket in addition to the pump housing spacer. I go to install the rear bolt last night and... the hole in the block isn't threaded? It's also not very deep (maybe 1/4"). Inspect with a mirror and light and it appears that someone busted the bolt off inside the block... and it's recessed in there. So the guy or a shop he had it looked at screwed something up and couldn't figure out what they did wrong. Every other bolt came out perfectly fine by the way, this isn't the rust belt so nothing is corroded.

Either way, something is wrong with that hole and a 7/16-14 screw won't go in. So now here I am. Surely I'm not the only one this has ever happened to. Do I have any options other than pulling the wheel well and drilling the remains out and praying I can get the threads to hold up\helicoil? Is there a way I can rig\fabricate something to hold the rear bracket and spacer properly by attaching it to the motor mount that's nearby (and has a thin bracket itself running over to the area)? Because drilling and tapping in that area is going to suck and I would really like to avoid it if possible.

Or just find another engine (307\350) and swap it in place? Seems like a lot of work for one broken off bolt...

Yes, I do know pictures would help. I'll add them when I get home later.

#4

Grr... how deep is the hole normally? Would hate to drill it too far and punch into some place I'd rather not go. Drill and tap! 7/16-14 threads?

I was thinking the guy probably forgot the spacer and cranked down on the bolt until it snapped off.

I was thinking the guy probably forgot the spacer and cranked down on the bolt until it snapped off.

#5

No, you need an easy-out, not a tap. That bolt hole is in the crankcase, not the cooling jacket, so at worst you'd have a small oil leak. RTV on the bolt would fix that.

#6

We'll see. I'm not sure how easy it will be to get a drill in that area without pulling the engine. I have my left handed drill set and extractor bits, so hopefully I can get the remains out without damaging the threads.

#7

Don't. Call around your local muffler shops and see if any of them have a skilled welder on staff. It's an easy matter to weld a nut on that broken bolt end (1/4" below surface is no problem at all, if he can see it) and run it back out. Any shop that commonly does exhaust manifolds will certainly have someone with experience. Nine time outta ten the threads are perfect afterwards.

#8

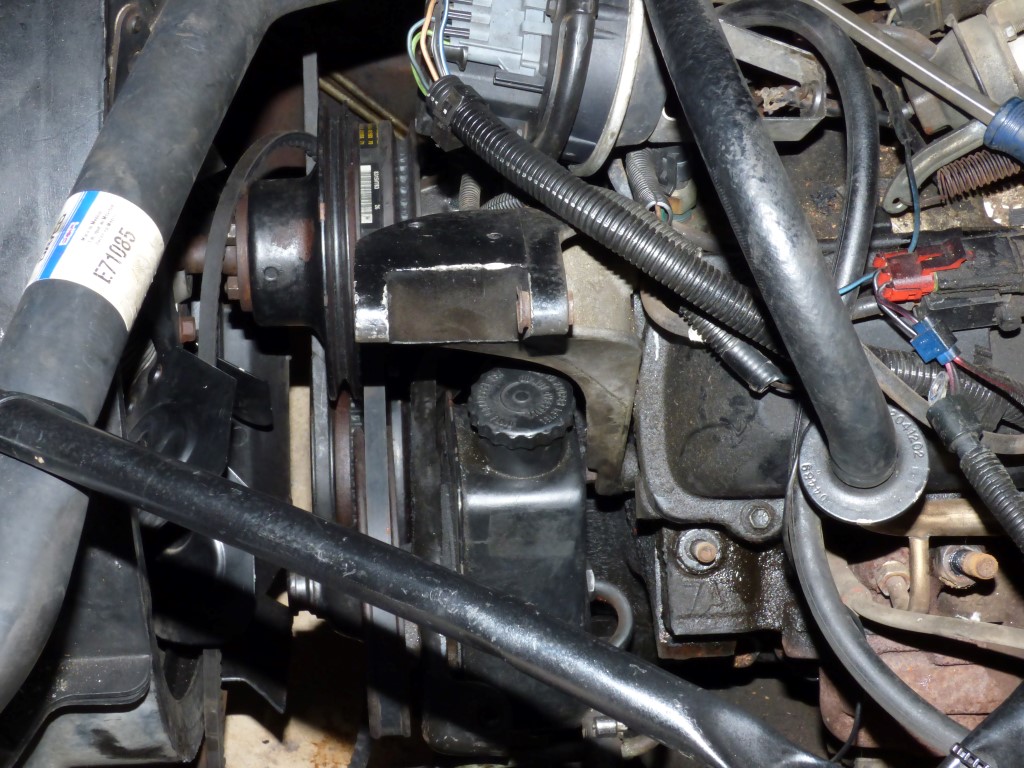

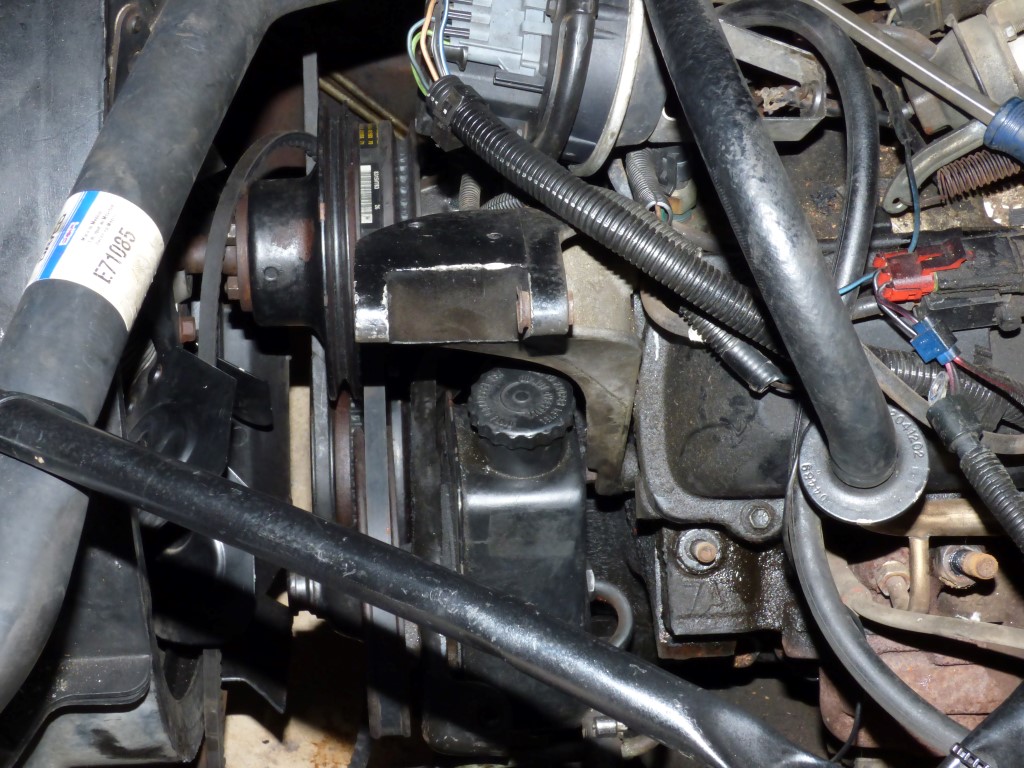

Well, this took a turn for the interesting tonight. I shone a light and got up close and personal with that area, finding that there was a large shim installed.

When I got my head right up next to it, I realized that it was blocked... but not by a broken bolt, but because the large shim had slipped up, blocking the hole almost entirely. I ended up loosening the block mount nut (which required removing the knock sensor) and using a large screwdriver to pry the engine up and the shim down, allowing the proper bolt to go in place:

I measured the shim and it is 0.310" thick, so I added a 0.090" washer I had laying around and then installed the lower bracket on:

And now the power steering pump is almost perfectly aligned:

I tensioned the belt tonight and it seems to be ok. Obviously firing it up will tell the tale, the power steering pump bracketry is missing 3 bolts so I have to hunt those down to finish up.

Was this setup factory or did someone get creative 15+ years ago?

When I got my head right up next to it, I realized that it was blocked... but not by a broken bolt, but because the large shim had slipped up, blocking the hole almost entirely. I ended up loosening the block mount nut (which required removing the knock sensor) and using a large screwdriver to pry the engine up and the shim down, allowing the proper bolt to go in place:

I measured the shim and it is 0.310" thick, so I added a 0.090" washer I had laying around and then installed the lower bracket on:

And now the power steering pump is almost perfectly aligned:

I tensioned the belt tonight and it seems to be ok. Obviously firing it up will tell the tale, the power steering pump bracketry is missing 3 bolts so I have to hunt those down to finish up.

Was this setup factory or did someone get creative 15+ years ago?

#10

That is different then my 88 Cutlass. Olds did usually tie in the back of the power steering bracket into the motor mount bolt. Mine has a tail off the pump bracket that goes over top of the mount. Quite often the brackets were different to fit different bodies and options.

#11

I forgot this was a Caddy and not an Olds. For some reason, Cadillac used different motor mounts and frame mounts than did Olds in the same chassis and with the same 307 Olds motor. Go figure. Most of the Fleetwoods I've seen with the 307 actually use Chevy clamshell frame mounts and metal brackets on the motor that look like the 403 Trans Am brackets.

This "shim" actually looks a lot like the adapter used to slide the motor mount forward on the Olds diesel motors to clear the larger starter. Since this is an 89, it could not have been a diesel. I wonder if the frame mounts are actually Caddy 4100 mounts and this adapter moves the motor mount accordingly? Is there a similar adapter on the passenger side?

This "shim" actually looks a lot like the adapter used to slide the motor mount forward on the Olds diesel motors to clear the larger starter. Since this is an 89, it could not have been a diesel. I wonder if the frame mounts are actually Caddy 4100 mounts and this adapter moves the motor mount accordingly? Is there a similar adapter on the passenger side?

#12

Well, got engine all back together tonight and fired it up. Squealed like crazy... from the water pump. The A.I.R. belt was nice and cool after 5 minutes of running but the alternator and the power steering belts were soft and gooey and WAY too hot to touch. Smoke started pouring out from underneath the fan pulley setup. And the alternator isn't charging. Looks like the water pump bearing is toast. Guess I'm pulling it back apart and replacing it, not sure how someone can botch a water pump install.

The alternator belt is REALLY close to the water pump pulley. It seems like it should be spaced at least 1/4" apart from each other but this is more like 1/16" if that. How much clearance is there supposed to be between the two? Service manual for this era is pretty useless in that manner.

The alternator belt is REALLY close to the water pump pulley. It seems like it should be spaced at least 1/4" apart from each other but this is more like 1/16" if that. How much clearance is there supposed to be between the two? Service manual for this era is pretty useless in that manner.

#13

And the conclusion from today:

Dismantle the AC compressor and A.I.R. pump mounting brackets and hardware, add the missing spacers, put all hardware in correct spots, add the missing spacer behind the upper power steering pump mounting bolt, and tension all 4 brand new belts correctly. Car fires up and runs at fast idle, high idle, and regular idle in gear and out without a single squeak. Steering wheel was put lock to lock at idle without making a single noise. Amazing how if you put it all together the way the General specified when it was new it just works... water pump seems to be fine and moves water to the best of my ability to tell from limited testing (alternator isn't charging, need to figure that out next).

I'm not convinced that the AC compressor belt was absolutely required as many people have said over the years as the contact surface on the water pump pulley is less than 20%, but I still put them all on.

Dismantle the AC compressor and A.I.R. pump mounting brackets and hardware, add the missing spacers, put all hardware in correct spots, add the missing spacer behind the upper power steering pump mounting bolt, and tension all 4 brand new belts correctly. Car fires up and runs at fast idle, high idle, and regular idle in gear and out without a single squeak. Steering wheel was put lock to lock at idle without making a single noise. Amazing how if you put it all together the way the General specified when it was new it just works... water pump seems to be fine and moves water to the best of my ability to tell from limited testing (alternator isn't charging, need to figure that out next).

I'm not convinced that the AC compressor belt was absolutely required as many people have said over the years as the contact surface on the water pump pulley is less than 20%, but I still put them all on.

Thread

Thread Starter

Forum

Replies

Last Post