Modern rag joints can make your horn work intermittently

#1

Modern rag joints can make your horn work intermittently

I've been living with an intermittent horn for a couple of years now. The worked when turning, but not when going straight.

I just finished a 3 day odyssey to get it working properly. This car is a 66 Starfire with the tilt & tele column, but the horn principles here should apply to GM cars from the early 60's probably into the mid 70's.

Horn Design

In these cars there is a black (+) power wire going into the column coming from the main harness. The negative (-) lead is the column itself. As originally designed the steering column connects to the steering box through a rubber rag joint. The steering box is bolted to the frame, so it's grounded.

Old vs. New Rag joints

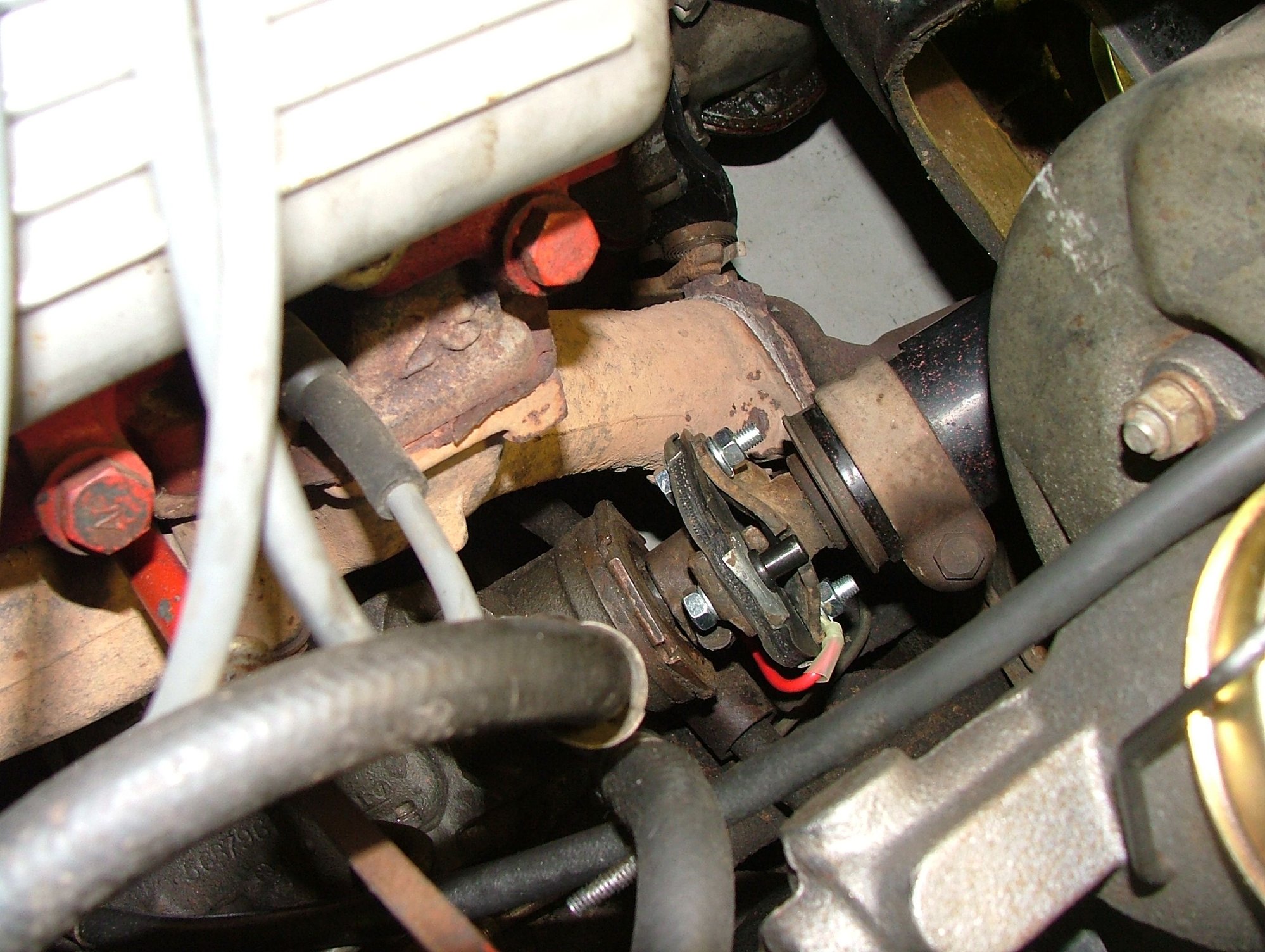

In the 1960's, rag joints came with a copper or brass grounding strap to transmit the negative grounding electrical connection up through the column since rubber doesn't conduct electricity. Some (maybe all) latter day, modern rag joints don't come with grounding straps. Newer rag joints have metal strands in them which are supposed to replace the ground strap. My rag joint is 4 or 5 years old, not worn out. It actually looks pretty new.

I believe that when you suspend metal strands in the rag joint, the rubber eventually moves enough, or deforms enough to break the strands. Which leaves you with an intermittent horn.

Diagnosing the problem

I found the problem when I touched a test light to the very top of the column shaft & got no light. The test light was powered by the dome/courtesy fuse holder so I knew there was power to the test light.

The fix is either replace the rag joint, or simply add a ground strap to the rag joint. I used a bit of braided wire, cleaned everything for a good ground and even soldered the braid into the terminal.

Hope this saves you all some time. Many thanks to OldCutlass for recommending I look at the rag joint!

My horn finally works again!

Chris

I just finished a 3 day odyssey to get it working properly. This car is a 66 Starfire with the tilt & tele column, but the horn principles here should apply to GM cars from the early 60's probably into the mid 70's.

Horn Design

In these cars there is a black (+) power wire going into the column coming from the main harness. The negative (-) lead is the column itself. As originally designed the steering column connects to the steering box through a rubber rag joint. The steering box is bolted to the frame, so it's grounded.

Old vs. New Rag joints

In the 1960's, rag joints came with a copper or brass grounding strap to transmit the negative grounding electrical connection up through the column since rubber doesn't conduct electricity. Some (maybe all) latter day, modern rag joints don't come with grounding straps. Newer rag joints have metal strands in them which are supposed to replace the ground strap. My rag joint is 4 or 5 years old, not worn out. It actually looks pretty new.

I believe that when you suspend metal strands in the rag joint, the rubber eventually moves enough, or deforms enough to break the strands. Which leaves you with an intermittent horn.

Diagnosing the problem

I found the problem when I touched a test light to the very top of the column shaft & got no light. The test light was powered by the dome/courtesy fuse holder so I knew there was power to the test light.

The fix is either replace the rag joint, or simply add a ground strap to the rag joint. I used a bit of braided wire, cleaned everything for a good ground and even soldered the braid into the terminal.

Hope this saves you all some time. Many thanks to OldCutlass for recommending I look at the rag joint!

My horn finally works again!

Chris

#3

Just a note, the black wire is not positive, it is the negative side of the circuit. The positive side is at the horn relay itself. Glad the issue turned out to be a missing ground strap at the rag joint. Makes for an easy fix.

#5

Eric,

Many thanks for the tip on the relay interaction. I’ve been so focused on the column, I didn’t spend anytime on the related components. Until I did.

Without your timely tip on the rag joint I’d still be growling in the garage instead of enjoying a perfect Fall 78 degree afternoon with beverage in hand.

Many thanks for saving my sanity. At the point of your post I was out of ideas since all the pieces are parts were unit testing perfectly, but they didn’t work perfect when fitted together.

What’s funny is an offhand comment by Leno on Jay Leno’s Garage was what pushed me into the project. One of the episodes he was talking about all kinds of rare & expensive cars that look perfect “But then the horn doesn’t work!”. Between that and all the times I get cutoff in traffic when I leave tons of room ahead of me, it was time to repair the horn.

Cheers

Chris

Many thanks for the tip on the relay interaction. I’ve been so focused on the column, I didn’t spend anytime on the related components. Until I did.

Without your timely tip on the rag joint I’d still be growling in the garage instead of enjoying a perfect Fall 78 degree afternoon with beverage in hand.

Many thanks for saving my sanity. At the point of your post I was out of ideas since all the pieces are parts were unit testing perfectly, but they didn’t work perfect when fitted together.

What’s funny is an offhand comment by Leno on Jay Leno’s Garage was what pushed me into the project. One of the episodes he was talking about all kinds of rare & expensive cars that look perfect “But then the horn doesn’t work!”. Between that and all the times I get cutoff in traffic when I leave tons of room ahead of me, it was time to repair the horn.

Cheers

Chris

#7

Exactly right. Great pictures.

Missing grounding strap was quite a discovery for me. Turns out Corvette people have this problem all the time and other Chevy owners too,

I went with braided wire on mine because I had one at hand & I thought it really looked like a grounding strap. Then I patted myself on the back for soldering it up properly. I expect it will last many many more years.

Wishing you long life on your repair too. Something so simple took me 3 days to trace down & I would not gotten there without help from our friends at CO.

Cheers

Chris

Missing grounding strap was quite a discovery for me. Turns out Corvette people have this problem all the time and other Chevy owners too,

I went with braided wire on mine because I had one at hand & I thought it really looked like a grounding strap. Then I patted myself on the back for soldering it up properly. I expect it will last many many more years.

Wishing you long life on your repair too. Something so simple took me 3 days to trace down & I would not gotten there without help from our friends at CO.

Cheers

Chris

Thread

Thread Starter

Forum

Replies

Last Post

Doctor's Olds

Vintage Oldsmobiles

3

August 26th, 2022 11:03 AM

vCode442

General Discussion

7

April 1st, 2020 10:09 AM