TKO swap, help me do it right.

#1

TKO swap, help me do it right.

Alright, I'm swapping a TKO500 into my '72 auto Supreme. The transmission arrived from Florida this week, so I decided to mock it up against my bellhousing. First problem already identified!

The transmission it all its glory!

swUjvWC.jpg

Said problem with the bellhousing. Is it safe to remove the few millimeters from the hole in the bellhousing to make it fit?

nP7x5KG.jpg

Now, just for verification - this IS the way my hydraulic clutch and centerforce should be fitted, yes?

20PEC37.jpg

EsZMyKg.jpg

JEWEIu2.jpg

And this one, fitted like in the first or the second picture? I don't have the flywheel yet, so I can't mock the clutch up against it.

vMU2t7d.jpg

9sAyNGO.jpg

This thread will be updated when I have all the parts and can start screwing with crossmembers and floor clearance. Will be fun.

The transmission it all its glory!

swUjvWC.jpg

Said problem with the bellhousing. Is it safe to remove the few millimeters from the hole in the bellhousing to make it fit?

nP7x5KG.jpg

Now, just for verification - this IS the way my hydraulic clutch and centerforce should be fitted, yes?

20PEC37.jpg

EsZMyKg.jpg

JEWEIu2.jpg

And this one, fitted like in the first or the second picture? I don't have the flywheel yet, so I can't mock the clutch up against it.

vMU2t7d.jpg

9sAyNGO.jpg

This thread will be updated when I have all the parts and can start screwing with crossmembers and floor clearance. Will be fun.

#2

On the first pic, are you saying the trans bearing retainer is too large to fit in the bell? If so what bell is it, and are you sure your TKO is not a ford application. The ford TKOs have a larger bearing retainer diameter and longer inout shaft.

And no, it's not OK to trim the bell. That hole is machined to center the trans to the crank/flywheel

............................. GM Ford

bearing retainer dia 4.683 4.849

Input shaft length 6.66 7.18

And no, it's not OK to trim the bell. That hole is machined to center the trans to the crank/flywheel

............................. GM Ford

bearing retainer dia 4.683 4.849

Input shaft length 6.66 7.18

#3

It IS a Ford application tranny. The bell is original from a Buick. Get an aftermarket bell housing, or look for a GM bearing retainer? Will only a TKO one work, or will any off a 4 speed?

Is it advisable to trim the input shaft? I had the bearing retainer off, the splines continue under it a ways down the shaft.

Is it advisable to trim the input shaft? I had the bearing retainer off, the splines continue under it a ways down the shaft.

#4

You have a lot of problems with the ford trans. In addition to the bearing retainer and input shaft length, the input shaft spline diameter is different and so is the pilot bearing.

There are several ways to make it work, none very easy, and the Olds bell pattern doesn't make it any better. Can you machine an adapter plate and pilot bushing?

My suggestion, contact some of the TKO dealers that sell GM versions. Check to see if you can swap out the input shaft and bearing retainer for the GM version.

There are several ways to make it work, none very easy, and the Olds bell pattern doesn't make it any better. Can you machine an adapter plate and pilot bushing?

My suggestion, contact some of the TKO dealers that sell GM versions. Check to see if you can swap out the input shaft and bearing retainer for the GM version.

#5

When you do get all of the right parts do not forget to center the bell housing. You may have to get offset dowels to do this. This is a critical step when converting form an automatic to a stick.

#8

TKO vendor has been contacted, we'll see what he says.

Thinking out loud: If the main shaft could be trimmed and the bearing retainer made smaller, I could buy myself a Ford clutch plate that would fit the splines. Does the pilot bearing need to have a smaller or larger hole for a Ford shaft?

Thinking out loud: If the main shaft could be trimmed and the bearing retainer made smaller, I could buy myself a Ford clutch plate that would fit the splines. Does the pilot bearing need to have a smaller or larger hole for a Ford shaft?

#9

I cant tell from the pics if your trans has a Muncie or newer ford style bell to trans bolt pattern. Kinda looks like muncie pattern. You can make a 1/2" adapter plate between the trans and bell to make up for the extra input shaft length. If you go over to corvette forum, C3 tech board, search for a ford T5 swap. There are dimensions for CNC machining the spacer. You definitely will need to zero in the bell.

The ford pilot is larger. You can have a pilot bushing machined for the correct dimension.

One aspect that I've never run across is what clutch/pressure plate combo will work in the BOP bell.

You'll also have to shim your throwout bearing for that installation.

The ford pilot is larger. You can have a pilot bushing machined for the correct dimension.

One aspect that I've never run across is what clutch/pressure plate combo will work in the BOP bell.

You'll also have to shim your throwout bearing for that installation.

#10

The tranny has bolt holes that fit the muncie pattern, no worries there.

I was gonna make shims that fit the hydraulic clutch mechanism (I assume that's the throwout bearing you're talking about), that's the least of my worry. It came with six shims, but they're not big enough in inner diameter to fit over the bearing retainer.

Zeroing the bell means centering it around the bearing retainer? Or does it mean moving the transmission around until the pilot spins freely in the pilot bearing with the transmission on the engine?

I'll look for that adapter plate pattern.

I was gonna make shims that fit the hydraulic clutch mechanism (I assume that's the throwout bearing you're talking about), that's the least of my worry. It came with six shims, but they're not big enough in inner diameter to fit over the bearing retainer.

Zeroing the bell means centering it around the bearing retainer? Or does it mean moving the transmission around until the pilot spins freely in the pilot bearing with the transmission on the engine?

I'll look for that adapter plate pattern.

#11

Typically zeroing in a bell involves using a dial gauge attached to the flwheel and making sure the bell housing cutout for the bearing retainer is centered to the crank. If you go with an adapter, you'll need to secure it to the bell, then measure it to see if it;s centered. Offset dowel pins are typically available in 0.007, 0.014, and 0.021 offsets. There are instructions online and at TKO sellers sites (Keisler) on how to do this.

#13

Alright, the bearing retainer is too fat for the bell-housing to come within ½" of the transmission. I'm looking at the following problems:

- non-Muncie transmission bolt pattern

- input shaft too long

- input spline diameter too narrow

- Bearing retainer too big

That leaves me with two possibilities

1. Trim bearing retainer and use a ½" spacer with the BOP OEM bell housing, and a Ford clutch plate with the existing centerforce setup. Drill out pilot bearing.

2. Find a GM bearing retainer, input shaft, buy a 26-spline clutch plate and a bell housing that fits both BOP and a Ford tranny.

To me, the first sounds the cheapest and easiest.

EDIT: Aditionally, is any of this untrue? http://www.novak-adapt.com/catalog/a...ford_to_gm.htm

- non-Muncie transmission bolt pattern

- input shaft too long

- input spline diameter too narrow

- Bearing retainer too big

That leaves me with two possibilities

1. Trim bearing retainer and use a ½" spacer with the BOP OEM bell housing, and a Ford clutch plate with the existing centerforce setup. Drill out pilot bearing.

2. Find a GM bearing retainer, input shaft, buy a 26-spline clutch plate and a bell housing that fits both BOP and a Ford tranny.

To me, the first sounds the cheapest and easiest.

EDIT: Aditionally, is any of this untrue? http://www.novak-adapt.com/catalog/a...ford_to_gm.htm

Last edited by Seff; February 11th, 2013 at 11:13 AM. Reason: Added the link.

#14

Wait, is the trans to bellhousing bolt pattern the same on both? Is it the wide Muncie or tall narrow ford?

If they dont match, there's the CNC diagram I mentioned earlier that fits between the trans and bell. It moves the trans back the correct distance too and the cutout is machined for the larger Ford bearing retainer.

Then all you need is to drill the pilot bushing and find a ford clutch disc that works with the Olds pressure plate.

If they dont match, there's the CNC diagram I mentioned earlier that fits between the trans and bell. It moves the trans back the correct distance too and the cutout is machined for the larger Ford bearing retainer.

Then all you need is to drill the pilot bushing and find a ford clutch disc that works with the Olds pressure plate.

#15

The bearing retainer is too large for that to work without trimming either bell housing or bearing retainer, as the closest I can cram the bell down over the retainer is 14 mm from the transmission, which is more than the 12.7mm that is ½" inch.

Turning down the retainer can easily be done, though, especially since it's just the corner of it.

Turning down the retainer can easily be done, though, especially since it's just the corner of it.

#16

Forgot to answer that bit, no; the tranny has the tall Ford bolt pattern.

You mean this one?

It seems incomplete, but I'll go measure my own and make a drawing from that. Shouldn't been too difficult.

You mean this one?

It seems incomplete, but I'll go measure my own and make a drawing from that. Shouldn't been too difficult.

#17

The Ford input shaft is 13.2 mm longer than the GM input shaft. The bell housing needs to be 14 mm in front of the transmission. Is that 0.8 mm too short acceptable in an application like this? 0.8 mm is 1/32".

#18

Ok earlier you said "The tranny has bolt holes that fit the muncie pattern, no worries there."

So the trans and bell do have different bolt patterns?

The diagram I'm referring to had both the Ford and Chevy bolt patterns. The 1/2" plate works for the T5, but it sounds like the TKO might have a thicker bearing retainer. Might be easier to trim the aluminum bell after the adpter is bolted on.

Since the bolt pattern is different and you'll need to move the trans back, you'll still need the adapter plate. The length doesnt have to be exact. The input shaft cant bottom out in the crank or taper on the pilot bushing, but should be seated the full depth of the bushing. The clutch disk splines should fully engage the splines on the input shaft too.

It's important that the adapter be bolted to the bell, then check for runout on the bearing retainer. The trans is centered based on the nearing retainer and it's tight fit to the bell (or adapter). Any trimming of the retainer would have to be machined to keep it correctly centered.

Here's one writeup. Looks like they marked the trans bolt holes after it was bolted to the plate.

http://forums.corvetteforum.com/c3-t...nsmission.html

So the trans and bell do have different bolt patterns?

The diagram I'm referring to had both the Ford and Chevy bolt patterns. The 1/2" plate works for the T5, but it sounds like the TKO might have a thicker bearing retainer. Might be easier to trim the aluminum bell after the adpter is bolted on.

Since the bolt pattern is different and you'll need to move the trans back, you'll still need the adapter plate. The length doesnt have to be exact. The input shaft cant bottom out in the crank or taper on the pilot bushing, but should be seated the full depth of the bushing. The clutch disk splines should fully engage the splines on the input shaft too.

It's important that the adapter be bolted to the bell, then check for runout on the bearing retainer. The trans is centered based on the nearing retainer and it's tight fit to the bell (or adapter). Any trimming of the retainer would have to be machined to keep it correctly centered.

Here's one writeup. Looks like they marked the trans bolt holes after it was bolted to the plate.

http://forums.corvetteforum.com/c3-t...nsmission.html

Last edited by garys 68; February 11th, 2013 at 10:47 PM.

#19

There is one other possibility worth checking. I think the F body cars with a T5 and a 3.8 had a bell with the BOP pattern and Ford trans/bell pattern. Not sure on the length though. Here in the states, they're really cheap and might be a direct bolt up.

Last edited by garys 68; February 11th, 2013 at 11:01 PM.

#21

Gary: I know I did, that's because I did the lineup in a hurry and thought that was the case. :P Not so.

If I need to seat the input shaft the full depth of the bushing, then going with a 12mm plate and machining either the bell or the retainer bearing seems the wisest. In any case I'm having the adapter plate made by a guy who can make it as accurate as possible, meaning that I don't need to worry about the tranny being centered afterwards.

In my quest for various 5-speed solutions, I've determined that there are few, if any, T-5s in Denmark, and certainly none with the BOP pattern bell. Plus, I'd still have an input shaft length problem. The adapter plate fixes both of these problems.

Marx: IS that the right part, though? Will it add the ½" so my input shaft length is correct? Otherwise I'm stuck buying an expensive lakewood bell, and THEN make an adapter plate afterwards, when I could just make an adapter plate.

If I need to seat the input shaft the full depth of the bushing, then going with a 12mm plate and machining either the bell or the retainer bearing seems the wisest. In any case I'm having the adapter plate made by a guy who can make it as accurate as possible, meaning that I don't need to worry about the tranny being centered afterwards.

In my quest for various 5-speed solutions, I've determined that there are few, if any, T-5s in Denmark, and certainly none with the BOP pattern bell. Plus, I'd still have an input shaft length problem. The adapter plate fixes both of these problems.

Marx: IS that the right part, though? Will it add the ½" so my input shaft length is correct? Otherwise I'm stuck buying an expensive lakewood bell, and THEN make an adapter plate afterwards, when I could just make an adapter plate.

#22

You're still going to need to zero in the bell with adapter attached. The old Muncies were pretty tolerant of runout, not so for the newer trans. A couple GM 621 bells I cheched were at 0.008 (close) and 0.020 (way out). It only takes 15 minutes, a dial indicator and mayby a set of $10 offset pins. If you bolt it up out of spec, it could drag or the misalignment between the input shaft gear and countershaft can kill the trans.

#23

We agree about that. The alternative is to measure the bell, then incorporate any offset in the adapter plate, which seems stupid.

I was talking about the adapter plate keeping the trans centered on the bell, since making an adjustable adapter plate isn't feasible when the bell holes are threaded.

I was talking about the adapter plate keeping the trans centered on the bell, since making an adjustable adapter plate isn't feasible when the bell holes are threaded.

#24

Sounds good. I dont think I've seen offset pins over 0.021 so you have to get it within that tolerance. Let us know what you find for a ford clutch disk that will work with the Olds plate/flywheel.

#25

Now I'm curious - we agree that as long as the overall diameter (10.4", 10.5", 11", etc) is the same, any clutch plate of the centerforce type (AKA, like the one I have now for a 10 spline GM) will work, yes? I mean, the only thing this clutch plate does is 'friction' on both sides, and turn the input shaft when it touches both the flywheel and the orange centerforce thingy in the pictures. Those friction surfaces SHOULD be the same for a Ford and a GM clutch plate, shouldn't they?

#26

When I was looking into it for an LS swap, I found a lot of the manufacturers do use the same dimensions for various clutch parts with just differences in thne spline and pressure plate mount hole. I did run into one issue with a GM flywheel where the center machined center only allows for the outer 3/4 of the disk to contact the flywheel. If you have an aftermarket clutch, contact the manufacturer and see if they have a Ford disk with the same dimensions as the Olds one.

#27

I will.

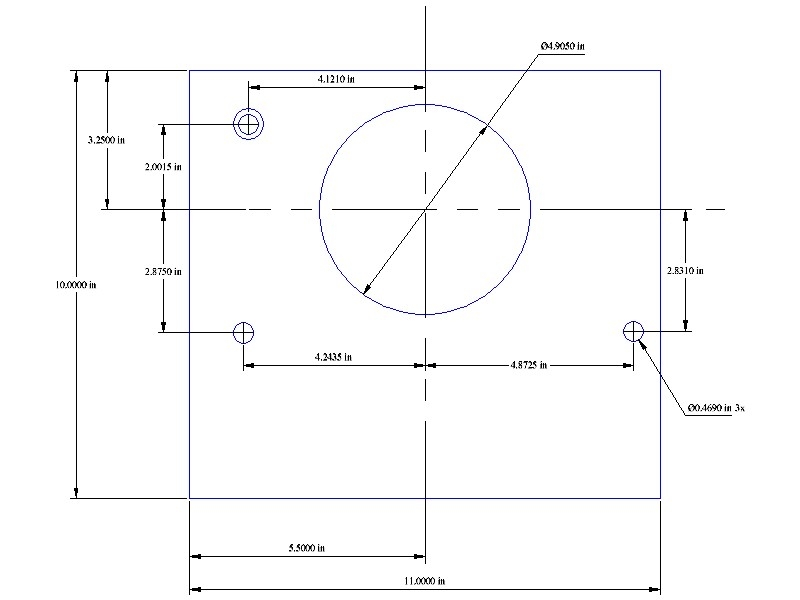

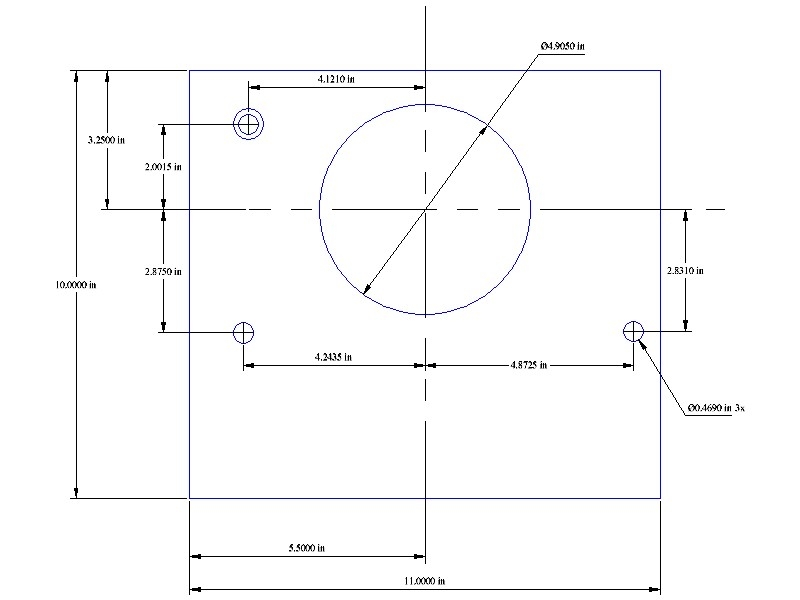

Here, I found dimensions for both TKO and Muncie, I'll go check my parts to see if they fit with these diagrams.

eF7fkEU.jpg

If they do, I can start making a detailed drawing for a machinist to work with.

Here, I found dimensions for both TKO and Muncie, I'll go check my parts to see if they fit with these diagrams.

eF7fkEU.jpg

If they do, I can start making a detailed drawing for a machinist to work with.

#28

ejIoevc.png

That's the plate needed. Will ream the two top holes in the trans to fit the bell, and fit the rest where it lines up. Should be good.

That's the plate needed. Will ream the two top holes in the trans to fit the bell, and fit the rest where it lines up. Should be good.

#29

wAQTGrt.jpg

Scrap yard made me a nice piece of metal to pass along to my friend who is a tool smith and will machine the adapter.

Scrap yard made me a nice piece of metal to pass along to my friend who is a tool smith and will machine the adapter.

#32

Y5HF4hQ.jpg

Adapter plate in progress. The rest of the needed parts being collected in the US and prepared to be shipped over here.

Adapter plate in progress. The rest of the needed parts being collected in the US and prepared to be shipped over here.

#33

#37

http://www.novak-adapt.com/catalog/p...m1_to_ford.htm Got that one. I asked the seller if it fits my application, and it does, so I'm not anticipating any problems on that front.

#38

Be sure to double check everything, especially depth of the input shaft engagement in the pilot bushing. With the different shaft lengths and your spacer, they might have made the bearing to sit deeper in the crank.

#40

MbHaozS.jpg

Back from the machinist. Cost me $80 all in all, labor and materials. Will test it for fit this weekend.

Back from the machinist. Cost me $80 all in all, labor and materials. Will test it for fit this weekend.