200-4R questions that's going into my '72 Vista Cruiser

#1

200-4R questions that's going into my '72 Vista Cruiser

I am currently rebuilding the 200-4r transmission I picked up from one of our forum members in Virginia.

What number of teeth would I use to get a correct reading on my speedometer? I currently have the factory rear axle ratio. The 200-4R core was missing the governor and my understanding is that the speedometer is driven off a gear from the governor which I can get with a 13 tooth speedo gear or a 10 tooth (much more expensive)… I don’t know what the factory 200-4r governor uses, but it seems like one that's calibrated for my engine's lower rpm and performance would be best, since I probably don't want the shift point to be too high?...

Also, does anyone know roughly how long the throttle valve cable needs to be for the Vista? I seems like there is a 40” or 52" inch length available. What would be a good stall speed lock-up torque converter to use on the relatively heavy Vista Cruiser, for mostly daily driver type use on a stock 350 engine with the 4 barrel Rochester?

Thanks, Tom

What number of teeth would I use to get a correct reading on my speedometer? I currently have the factory rear axle ratio. The 200-4R core was missing the governor and my understanding is that the speedometer is driven off a gear from the governor which I can get with a 13 tooth speedo gear or a 10 tooth (much more expensive)… I don’t know what the factory 200-4r governor uses, but it seems like one that's calibrated for my engine's lower rpm and performance would be best, since I probably don't want the shift point to be too high?...

Also, does anyone know roughly how long the throttle valve cable needs to be for the Vista? I seems like there is a 40” or 52" inch length available. What would be a good stall speed lock-up torque converter to use on the relatively heavy Vista Cruiser, for mostly daily driver type use on a stock 350 engine with the 4 barrel Rochester?

Thanks, Tom

#2

http://www.transmissioncenter.net/sp...n_______va.htm

#3

Thanks Joe! Is the ratio stamped somewhere into the outside of the diff anywhere or do I have to calculate it? Are you saying that a basic Vista Cruiser with a 2 barrel carb also had three different options. I would think that this car didn't have had anything but the standard option, but I should check just to be sure.

#4

Joe. I found this post and Jaunty mentioned the same gear ratios and how to find them on my diff:

As far as what rear-end gear ratio you have, the 1972 Olds Chassis Service Manual should be of help. It says that the differential ratio code letters are 1/4" high and are stamped on the "right front inboard side of the axle housing tube."

I would keep looking for these numbers as they are stamped into the metal and should not have worn away unless someone took a metal grinder and ground them off, which would be a weird thing to do.

The first two characters in the code should be, for a Cutlass Supreme, SA, SC, or SR, with these indicating, respectively, 2.73, 3.08, or 3.23 gear ratios. If the car is equipped with an anti-spin differential, the first two characters would be SB, SD, or SS, indicating the same three ratios.

The later characters indicate the manufacturer and the build date.

The gear teeth for the three ratios are, for SA/SB, 41:15; for SC/SD, 40:13, and for SR/SS, 42:13.

The ring gear size for all three is 8.5 inches, and they all have 10-bolt covers.

So we'll see if I can locate those stamped in numbers tomorrow before the game...

Thanks, Tom

As far as what rear-end gear ratio you have, the 1972 Olds Chassis Service Manual should be of help. It says that the differential ratio code letters are 1/4" high and are stamped on the "right front inboard side of the axle housing tube."

I would keep looking for these numbers as they are stamped into the metal and should not have worn away unless someone took a metal grinder and ground them off, which would be a weird thing to do.

The first two characters in the code should be, for a Cutlass Supreme, SA, SC, or SR, with these indicating, respectively, 2.73, 3.08, or 3.23 gear ratios. If the car is equipped with an anti-spin differential, the first two characters would be SB, SD, or SS, indicating the same three ratios.

The later characters indicate the manufacturer and the build date.

The gear teeth for the three ratios are, for SA/SB, 41:15; for SC/SD, 40:13, and for SR/SS, 42:13.

The ring gear size for all three is 8.5 inches, and they all have 10-bolt covers.

So we'll see if I can locate those stamped in numbers tomorrow before the game...

Thanks, Tom

#5

Joe. I just went under the VC to check out the stamped numbers on "the right front inboard side of the axle housing tube."

Unfortunately they say "SM", followed by a few numbers. Looks like ...075...

Is there any chance that SM means anything related to gear ratios on a 1972 Vista Cruiser?

Thanks, Tom

Unfortunately they say "SM", followed by a few numbers. Looks like ...075...

Is there any chance that SM means anything related to gear ratios on a 1972 Vista Cruiser?

Thanks, Tom

#6

I also just did 10 turns on one rear wheel and got 15 and 3/8 turns on the drive shaft. Does that give me a gear ratio of 1.5375 times 2? Equals 3.075 or 3.08, accounting for slight error in driveshaft turns?...

#7

3.08, due to the 2:1 ratio of the non-posi differential. I assume only one wheel turned.

#8

That's right Joe. I made sure one wheel was still touching the ground. I just read one of the other threads on swapping a 2004R into a Vista Cruiser, so it probably better for me to ask my question about lengthening the drive shaft there. Mine will also require roughly 6" of lengthening, but I just wanted to find out if that number was exact....

Thanks, Tom

Thanks, Tom

#9

New transmission is in. Still have a problem

Today, I installed my heavy duty rebuilt 200-4R. The great thing is that the transmission stock lines have expansion loops in them that allowed me to stretch them far enough to fit into the fittings with nothing except for a lot of careful bending so as not to kink the tubing. It's a little bit of a close fit past the hot exhaust headers, but it still looks like it could have come from the factory that way. The shift lever went in without a fuss too. The only problem I still see is that the transmission cross member doesn't line up as well as I thought it would. With the transmission mount connected to the cross member, I can only get one bolt on each side to line up with the three holes available in the frame rails. It seems like that would be enough, but since people had said the 200-4R would line up exactly I expected all four bolts to be in their original holes. It looks like the new drive shaft will have to be pretty much exactly 64" and I will use a 1310 to 1350 conversion u-joint to match up to my diff. I found a place on ebay (Southwest Speed) that makes a new drive shaft for around $200. It's only 63.5" long center to center, but they will supply a longer yoke in front to make up for the difference and I don't think the extra 1/2" yoke will do any harm...

#10

The only problem I still see is that the transmission cross member doesn't line up as well as I thought it would. With the transmission mount connected to the cross member, I can only get one bolt on each side to line up with the three holes available in the frame rails. It seems like that would be enough, but since people had said the 200-4R would line up exactly I expected all four bolts to be in their original holes.

#11

Is it possible the torque converter is not locked into the slot properly?

#12

#13

#14

Even Stevie Wonder would be able to tell if it weren't...

Seriously, the amount the crossmember appears to be off is more than the height that the dowel pins stick out of the block. You wouldn't even be able to get the bolts started if it were that far off.

The broken ear on the trans case from torquing those bolts would also have been a giveaway.

Seriously, the amount the crossmember appears to be off is more than the height that the dowel pins stick out of the block. You wouldn't even be able to get the bolts started if it were that far off.

The broken ear on the trans case from torquing those bolts would also have been a giveaway.

#15

The trans went in fine. I can only guess that we are talking about a different tail housing? As far as I know I had the original TH375 transmission, which I believe is the same as the TH350, but has as heavier duty output yoke, etc. My memory could be wrong on this. I measured the distance between the bell housing in as straight a line as I could to the center of the mounting holes on the tail shaft housing. It was about 27.75". That is with the 9.5" tail housing, total length. On the 200-4R the distance is right about 27", enough for the cross member not to line up quite right. What I did for now is move only one end of the cross member forward to catch the next hole in the frame member. That means I can only use one bolt on the one side to attach to the cross member, but I'm not worried that it will go anywhere. This kind of twists the transmission mount a little bit, but it was a quick fix before I decide if I want to drill more holes in the frame.

Maybe you are thinking of another tail housing in your comparison, Joe? Maybe that's also why I needed a longer drive shaft? Did a Vista Cruiser also come with a 3.5" tail housing for a TH375 that had a longer driveshaft instead?

Today, I hooked up my temperature gauge and sending unit in the transmission pan and shifted the steering column shift lever back and forth. The indicator is almost right on, just need to squeeze an OD between the D and N. Wasn't there a factory lettering indicator from an OD Olds. that someone said fits right in?

Thanks, Tom

Maybe you are thinking of another tail housing in your comparison, Joe? Maybe that's also why I needed a longer drive shaft? Did a Vista Cruiser also come with a 3.5" tail housing for a TH375 that had a longer driveshaft instead?

Today, I hooked up my temperature gauge and sending unit in the transmission pan and shifted the steering column shift lever back and forth. The indicator is almost right on, just need to squeeze an OD between the D and N. Wasn't there a factory lettering indicator from an OD Olds. that someone said fits right in?

Thanks, Tom

Last edited by tcolt; March 23rd, 2016 at 05:14 PM.

#16

One more thing. The new drive shaft I ordered came with 1310 U-joints. I was told that a 1350 conversion joint would bolt right up to my factory 10 bolt diff. I hope that's right. The end caps are 1.188", but it seems the distance end-to-end was more than the 1350 specs. at 1.695" vs. 1.625" for a 1350.

#17

The trans went in fine. I can only guess that we are talking about a different tail housing? As far as I know I had the original TH375 transmission, which I believe is the same as the TH350, but has as heavier duty output yoke, etc. My memory could be wrong on this.

Thanks, Tom

Thanks, Tom

The TH375 was a light-duty TH400, typically used in the VC and full size cars with the 350 motor. It has the normal TH400 case, but with lighter duty internals and a smaller diameter output shaft (the same dia as on a TH350). The TH375B is a heavy duty TH350 and is a completely different trans. The 375B uses the same case as a TH350, but with heavier duty internals.

The 72 VC frame (and all 68-72 VC frames) came with both sets of bolt holes for the trans crossmember. Yes, the TH400 (and TH375) was a long (9") tail, but the crossmember is in the same place as for any other TH400. The only thing that is affected by tailhousing is the driveshaft length. Bottom line is that if ANY TH400 or TH375 came out, the 200-4R is a direct bolt-in for the crossmember location. If a TH350 or TH375B came out, the crossmember needs to move back to the pre-drilled holes for the TH400. Are you sure the crossmember isn't flipped around? The raised lateral feature next to the trans mount location on the crossmember goes behind the mount.

#18

Thanks for trying to sort this out Joe. I checked again and the TH375 is correct at 27.935, but I still come up with about 27" for the 200-4R. These posts seem to support that length too.

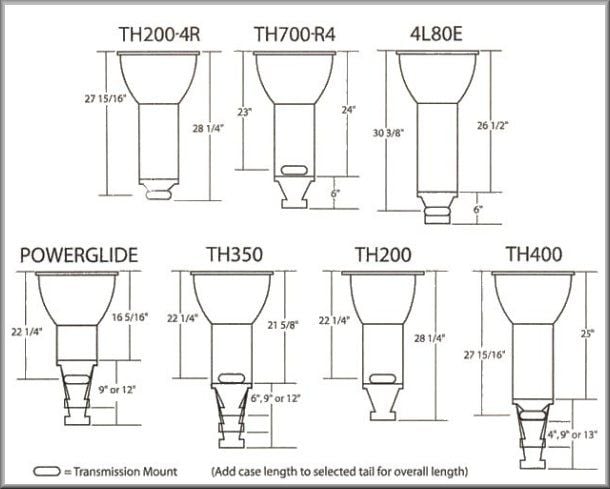

http://chevellestuff.net/tech/automa...dimensions.htm

http://www.thirdgen.org/forums/trans...een-200-a.html

What do you think about my 1350 conversion u-joint? Do you see any problems there?

I also found where someone posted that a 1964 to 1972 Nova shift column lens indicator will fit. Here is the link: http://www.shiftworks.com/kugel.htm

Tom

http://chevellestuff.net/tech/automa...dimensions.htm

http://www.thirdgen.org/forums/trans...een-200-a.html

What do you think about my 1350 conversion u-joint? Do you see any problems there?

I also found where someone posted that a 1964 to 1972 Nova shift column lens indicator will fit. Here is the link: http://www.shiftworks.com/kugel.htm

Tom

Last edited by tcolt; March 24th, 2016 at 12:12 AM.

#19

Thanks for trying to sort this out Joe. I checked again and the TH375 is correct at 27.935, but I still come up with about 27" for the 200-4R. These posts seem to support that length too.

http://chevellestuff.net/tech/automa...dimensions.htm

http://www.thirdgen.org/forums/trans...een-200-a.html

http://chevellestuff.net/tech/automa...dimensions.htm

http://www.thirdgen.org/forums/trans...een-200-a.html

#20

One more thing. The new drive shaft I ordered came with 1310 U-joints. I was told that a 1350 conversion joint would bolt right up to my factory 10 bolt diff. I hope that's right. The end caps are 1.188", but it seems the distance end-to-end was more than the 1350 specs. at 1.695" vs. 1.625" for a 1350.

The 13XX have an external snap ring. So pinion yokes typically have a little tab that sits outside the u-joint to keep the cap in place. 13XX also tend to use U-bolts, while GM3R tend to use straps.

Here's my favorite u-joint page:

http://www.driveshaftspecialist.com/...D%20Guide.html

FWIW, 1310 seems too small for a VC. 1350 is probably overkill. 3R is somewhat between a 1330 and 1350 for strength. Unless you're pushing a lot of power to a lot of traction, a quality u-joint of 1330 or 3R should be fine. Most places recommend sealed u-joints these days as the seals have gotten much better and the zerk has proven to be a stress point for breaking u-joints. Correct installation of a u-joint has a lot more to do with its survival, though.

#21

My VC originally came with what I believe to be 1350 U-joints that are held in the factory rear pinion yoke with u-bolts and to the drive shaft with pins through the forks on the yoke (no clips or staking). That is why my new shaft has to use 1350 there. The driveshaft company uses 1310 on all their shaft's u-joints and to fit with my rear end they use a conversion u-joint, 1310 to 1350. I was just making sure I got the correct one to fit my rear end, but it sounds like one can't go much wrong on this. The only thing that bothers me a bit is that the width on my factory joints is a little larger than the 3.622 quoted for a 1350 which might mean it won't center well?...

Joe. That would be something if there are two different 200-4R lengths, but I'm not taking mine apart again to put it all in a different case :-)...

Joe. That would be something if there are two different 200-4R lengths, but I'm not taking mine apart again to put it all in a different case :-)...

#22

I'm having trouble getting the dip stick tube into the transmission . Does anyone know the diameter of the tube where is goes into the grommet? Or should I leave the grommet away and only use the o-ring that was used for the dip stick tube when it was inside my TH375?

#23

I had a 200r4 put in my 72 vista a couple of years ago in preparation for a cross country drive. Stock 2.73 gears make it struggle a bit on any grade without downshifting. Lockup is disengaged by the brakes. Never connected great to the 2bbl, not enough travel for the downshift cable. Overall it was a success, but a throttle body EFI is in the near future.

#24

I had a 200r4 put in my 72 vista a couple of years ago in preparation for a cross country drive. Stock 2.73 gears make it struggle a bit on any grade without downshifting. Lockup is disengaged by the brakes. Never connected great to the 2bbl, not enough travel for the downshift cable. Overall it was a success, but a throttle body EFI is in the near future.

Where did you hook up the TV cable to the carburetor linkage? I had to build a small extension plate to the bottom of the linkage to achieve the travel that the TV valve requires. I'm even reading that the TV valve should already be pulled out about 3/8" when the carb. is at idle.

Last edited by tcolt; March 25th, 2016 at 12:22 PM.

#25

I'm still having a bit of trouble with the dip stick tube. When I install my old Vista Cruiser tube into the 200-4R with only the o-ring (the 200-4R grommet won't fit), the dip stick tube's mounting bracket ends up about an inch higher than the bolt hole on the bell housing. Do I have to find a dip stick tube specifically for a 200-4R?

Thanks, Tom

Thanks, Tom

#27

Thanks CW

Here is some more info for other people who plan on doing this themselves. I received the new driveshaft that I had made up. The longest I could get from the shop I chose was 63.5" which was 1/2" shorter than ideal. Instead, I asked them to supply a front yoke that was an 1" longer than my original yoke. Unfortunately, there was a mix up with the rear universal joint. They build their driveshafts with 1310 series joints, so I need a conversion joint in the back to fit what is called a GM 3R or S44 Saginaw differential yoke that has the right caps and spacing to adapt the rear end to the driveshaft. Yesterday, I tightened up my transmission mount and cross brace and rigged up my pressure gauge so I can test the transmission pressures according to Bowtie Overdrive Transmission's warranty instructions from when they used to build 200-4R transmissions. Although they don't really tell you the numbers that you should expect to see until you call them for warranty registration (which I obviously don't have since I built the transmission myself). If anyone knows what those numbers should be, please let me know. I'd like to make sure everything is right before I start any major test driving. Attached is a copy of their test procedure.

Here is some more info for other people who plan on doing this themselves. I received the new driveshaft that I had made up. The longest I could get from the shop I chose was 63.5" which was 1/2" shorter than ideal. Instead, I asked them to supply a front yoke that was an 1" longer than my original yoke. Unfortunately, there was a mix up with the rear universal joint. They build their driveshafts with 1310 series joints, so I need a conversion joint in the back to fit what is called a GM 3R or S44 Saginaw differential yoke that has the right caps and spacing to adapt the rear end to the driveshaft. Yesterday, I tightened up my transmission mount and cross brace and rigged up my pressure gauge so I can test the transmission pressures according to Bowtie Overdrive Transmission's warranty instructions from when they used to build 200-4R transmissions. Although they don't really tell you the numbers that you should expect to see until you call them for warranty registration (which I obviously don't have since I built the transmission myself). If anyone knows what those numbers should be, please let me know. I'd like to make sure everything is right before I start any major test driving. Attached is a copy of their test procedure.

#28

My memory could be wrong on this. I measured the distance between the bell housing in as straight a line as I could to the center of the mounting holes on the tail shaft housing. It was about 27.75". That is with the 9.5" tail housing, total length. On the 200-4R the distance is right about 27", enough for the cross member not to line up quite right.

#29

Joe. That's amazing. Now, you have me wondering if I measured something wrong, even though I did it twice on both of my 200-4Rs. Did you measure this in a straight line from the lower corner of the bell housing, parallel to the center line of the transmission and to the center line of the transmission bolt holes? I'm sure you did, as I did too.

Also, you have a '64 Vista. Maybe the frame holes are different, so they line up right for a 200-4R? On my frame there is one set for the TH375 and for the second set, both frame holes are located in front of the first set of holes. Those don't even come close to being usable with the 200-4R and I can't even really imagine what transmission would have been short enough to use them. Maybe for a manual transmission or the frame rails used different holes on other cars? That might also explain why you didn't need a longer drive shaft and mine needed to be a full 6" longer?

I couldn't help myself, so I just went out again and used an even more fool proof method to measure the distance. I set the transmission upright, straight on a flat surface (being careful that the bell housing stays flat on the ground and doesn't tip forward). I put the tape measure on the same surface and if anything it comes out closer to 26.75" to 26.875, which I think was close to what some of the other charts said. Maybe the 200-4R had two different locations for the transmission mount after all? You can see the measurement on the picture.

Yesterday, I finally bolted up my transmission mount to the cross member and then slightly twisted it so that one side lines up with the frame holes that my original transmission used and about 1 1/2" forward on the other side, held by just one bolt, since the second bolt is another 4 or 5" forward from that one. I didn't tighten the two bolts that hold the mount to the transmission and the two going through the cross member into the mount, until the cross-member was in place. That way the mount could twist slightly in all four holes and then I tightened it all down. Tomorrow, I'll see if my emergency brake cables were affected by the small movement of the cross member.

I should have the correct conversion joint for my new drive shaft tomorrow and hopefully this week, the Vista will be able to move under its own power for the first time a two months.

Also, you have a '64 Vista. Maybe the frame holes are different, so they line up right for a 200-4R? On my frame there is one set for the TH375 and for the second set, both frame holes are located in front of the first set of holes. Those don't even come close to being usable with the 200-4R and I can't even really imagine what transmission would have been short enough to use them. Maybe for a manual transmission or the frame rails used different holes on other cars? That might also explain why you didn't need a longer drive shaft and mine needed to be a full 6" longer?

I couldn't help myself, so I just went out again and used an even more fool proof method to measure the distance. I set the transmission upright, straight on a flat surface (being careful that the bell housing stays flat on the ground and doesn't tip forward). I put the tape measure on the same surface and if anything it comes out closer to 26.75" to 26.875, which I think was close to what some of the other charts said. Maybe the 200-4R had two different locations for the transmission mount after all? You can see the measurement on the picture.

Yesterday, I finally bolted up my transmission mount to the cross member and then slightly twisted it so that one side lines up with the frame holes that my original transmission used and about 1 1/2" forward on the other side, held by just one bolt, since the second bolt is another 4 or 5" forward from that one. I didn't tighten the two bolts that hold the mount to the transmission and the two going through the cross member into the mount, until the cross-member was in place. That way the mount could twist slightly in all four holes and then I tightened it all down. Tomorrow, I'll see if my emergency brake cables were affected by the small movement of the cross member.

I should have the correct conversion joint for my new drive shaft tomorrow and hopefully this week, the Vista will be able to move under its own power for the first time a two months.

#30

When I bought my 200-4R transmission it came with the dip stick tube, but not the dip stick. Since the transmission was completely empty after I rebuilt it, I figured I could put in 11.5 to 12 quarts of fluid including the oil cooler and an inline filter and get a good starting point for the fluid level so that I could calibrate my old th 375 dip stick. But that stick dip stick didn't fit at all so I check out the junk yards. I didn't know what I was going to find except that I searched any rear wheel drive cars from the mid eighties that I saw. I found 4 Buicks and Oldsmobiles and to my surprise they all had identical dip sticks even when they didn't all have 200-4r transmissions. That makes me a lot more confident that the dip stick I bought should very well be showing the correct fluid level for my 200-4R. What do you all think?...

Thanks, Tom

P.S. I did my first cautious test drives and everything seems to work well except that the pressures don't seem to increase as much as I thought they would and they don't increase at all by just pulling out the TV cable after I disconnect it. (Oddly, they do increase a bit just by blipping the throttle in the various gears). I guess, I'll just have to drop the pan and see if the TV valve is somehow stuck, since I can't imagine what else could cause this. The TV cable is connected and set-up correctly.

Thanks, Tom

P.S. I did my first cautious test drives and everything seems to work well except that the pressures don't seem to increase as much as I thought they would and they don't increase at all by just pulling out the TV cable after I disconnect it. (Oddly, they do increase a bit just by blipping the throttle in the various gears). I guess, I'll just have to drop the pan and see if the TV valve is somehow stuck, since I can't imagine what else could cause this. The TV cable is connected and set-up correctly.

#32

I had a certain level of paranoia about trans pressures / TV setting because of all the warnings about frying the trans. I ended up putting an autometer pressure gage under the dash connected to the pressure tap on the trans. When I hit the throttle in drive, pressure went up big time on the gage. Sorry but don't remember the numbers. Gauge is gone now so I cant get that for ya.

#33

Thanks for your help. I don't know if my solution is a swap or if it's the factory correct application for a 200-4R transmission. The dip stick I found belonged to a mid-eighties Cutlass and it was identical to other dip sticks that I found in three Buicks. The stock dip stick tube that I'm using with that was from a 1985 Olds Cutlass with a 200-4R transmission. Does anyone know if that dip stick tube and dip stick was so widely used that it fit most 80's BOP passenger cars with rear wheel drive?

Thread

Thread Starter

Forum

Replies

Last Post

Nunyadam Biz

The Newbie Forum

19

September 16th, 2020 05:49 AM

rustycragars

Small Blocks

6

October 5th, 2009 05:16 PM