Too much oil in head?

#1

Too much oil in head?

I rebuilt a set of E cylinder heads last fall. Before the rebuild I noticed the engine was burning oil and I did a compression check and all cylinders checked good so I decided to redo the heads. I had bronze guides, Viton seals, and bigger valves

The engine was rebuilt a few years ago and only has maybe 3000 miles on it

I noticed the car was smoking still so I removed the intake and found I have puddles of oil on the back sides of the intake valves. So I decided to buy aluminum valves and Iím worried that the problem is still going to happen. Does anyone have any suggestion or experience in this problem?

thank you

Dan

The engine was rebuilt a few years ago and only has maybe 3000 miles on it

I noticed the car was smoking still so I removed the intake and found I have puddles of oil on the back sides of the intake valves. So I decided to buy aluminum valves and Iím worried that the problem is still going to happen. Does anyone have any suggestion or experience in this problem?

thank you

Dan

#3

Aluminum valve covers we'll assume?

Sounds like you have excessive guide to valve stem clearance or bad/wrong seals. A head job performed poorly is NEVER GOOD.LOL.

Did you alter the oiling system at all? Hi PSI pump, oversized/wrong push rod oil through-holes etc?

Valvetrain stock?

Is the oil draining out of the head drains without restrictions? look down the holes for obstructions.

What type of stem seals did you use?

I assume you have inspected the seals visually with the valve covers off? Are the seals riding up on the stem?

Sounds like you have excessive guide to valve stem clearance or bad/wrong seals. A head job performed poorly is NEVER GOOD.LOL.

Did you alter the oiling system at all? Hi PSI pump, oversized/wrong push rod oil through-holes etc?

Valvetrain stock?

Is the oil draining out of the head drains without restrictions? look down the holes for obstructions.

What type of stem seals did you use?

I assume you have inspected the seals visually with the valve covers off? Are the seals riding up on the stem?

#5

Poor head job is like bad pizza.... Still good Or something like that

All jokin aside The oil system is stock, the drain back is open and flowing. The valve train is comp cam adjustable rockers with the roller tip The valve job was done with milodon stainless valves, bronze guides and blue style positive seal, seals.

My thinking is, it wouldn’t matter how much oil is pumped up in the valve cover area, it shouldn’t leak into the valve area if the seals and guides are good? Right?

How tight should the intake valves be in the guides? They are the ones that seem to be most effected

The cylinder heads were magnafluxed and no cracks were found

Also the pushrods are comp with .080 oil holes

All jokin aside The oil system is stock, the drain back is open and flowing. The valve train is comp cam adjustable rockers with the roller tip The valve job was done with milodon stainless valves, bronze guides and blue style positive seal, seals.

My thinking is, it wouldn’t matter how much oil is pumped up in the valve cover area, it shouldn’t leak into the valve area if the seals and guides are good? Right?

How tight should the intake valves be in the guides? They are the ones that seem to be most effected

The cylinder heads were magnafluxed and no cracks were found

Also the pushrods are comp with .080 oil holes

Last edited by Daniel828; March 15th, 2019 at 01:39 PM.

#13

Where the heads milled ? I recently experienced and issue where my intake was not mating with the cylinder heads properly. I not only had intake gaskets wicking out oil but I was burning it. I stuck and borescope into the intake and saw traces of oil on the intake runner floors on the heads but the intake runner floors where clean on the manifold . I could have machined the intake but I found thin intake manifold gaskets to fix my issues and milling my intake would have severely screwed the extensive port work that was done to match the heads.

Also did you do a leak down test ? that would tell you more than a compression test imo specially on pin pointing where the leak is coming from.

Also did you do a leak down test ? that would tell you more than a compression test imo specially on pin pointing where the leak is coming from.

Last edited by coppercutlass; March 15th, 2019 at 09:27 PM.

#14

The prob is definitely not the pcv. That line is dry

all the intake valves have puddles of oil on them

I shouldíve taken pics but the heads are off the engine now and the oil has leaked on to the bench

also , I didnít do a leak down test unfortunately as everything is apart

The intake gaskets seemed dry and were stuck to the heads but not to the intake

IS there enough vacuum produced on the intake stroke to pull oil from the valley ?

Actually that doesnít make sense because the oil is puddling after the engine is turned off. It must be leaking down the valve stem past the guide

all the intake valves have puddles of oil on them

I shouldíve taken pics but the heads are off the engine now and the oil has leaked on to the bench

also , I didnít do a leak down test unfortunately as everything is apart

The intake gaskets seemed dry and were stuck to the heads but not to the intake

IS there enough vacuum produced on the intake stroke to pull oil from the valley ?

Actually that doesnít make sense because the oil is puddling after the engine is turned off. It must be leaking down the valve stem past the guide

#15

If the oil is wicking through the gasket it will get sucked down into the valve during vacuum. But the puddling on the valve I missed that part. I would get a bore scope and try to see where the oil is coming in from. If its the guide it would be easy to see with a borescope. But..... Oil is slung and does cling to the intake. It's not farfetched to possibly think it finds its way to the valve. Checking the valve for loosened at the guide is pretty easy with a dial indicator and magnetic base.

Last edited by coppercutlass; March 15th, 2019 at 11:22 PM.

#16

What does the perimeter of the pistons look like? An even amount of carbon on the tops or less around the outer edges?

Last edited by cutlassefi; March 16th, 2019 at 07:20 AM.

#17

I was advived to not mill the intake because if it was just a mis aligned flange as in it not being square to the head surface the cut necessary to fitlx it could have cause more issues than fixed due to the fact the intake was ported to match the heads. Again just being cautious. So a reputable olds racing engine builder adviced me to try thinner gaskets before we go with more evasive measures. Not that it's bit the same as milling just less evasive and more cautious when everything has been set in stone . as far as the pistons go it didnt consume enough oil to leave anything behind. There was just light trace marks of oil being sucked in or wicking in. Engine had almost no run time at this point and it was still in the shake down phases.

#18

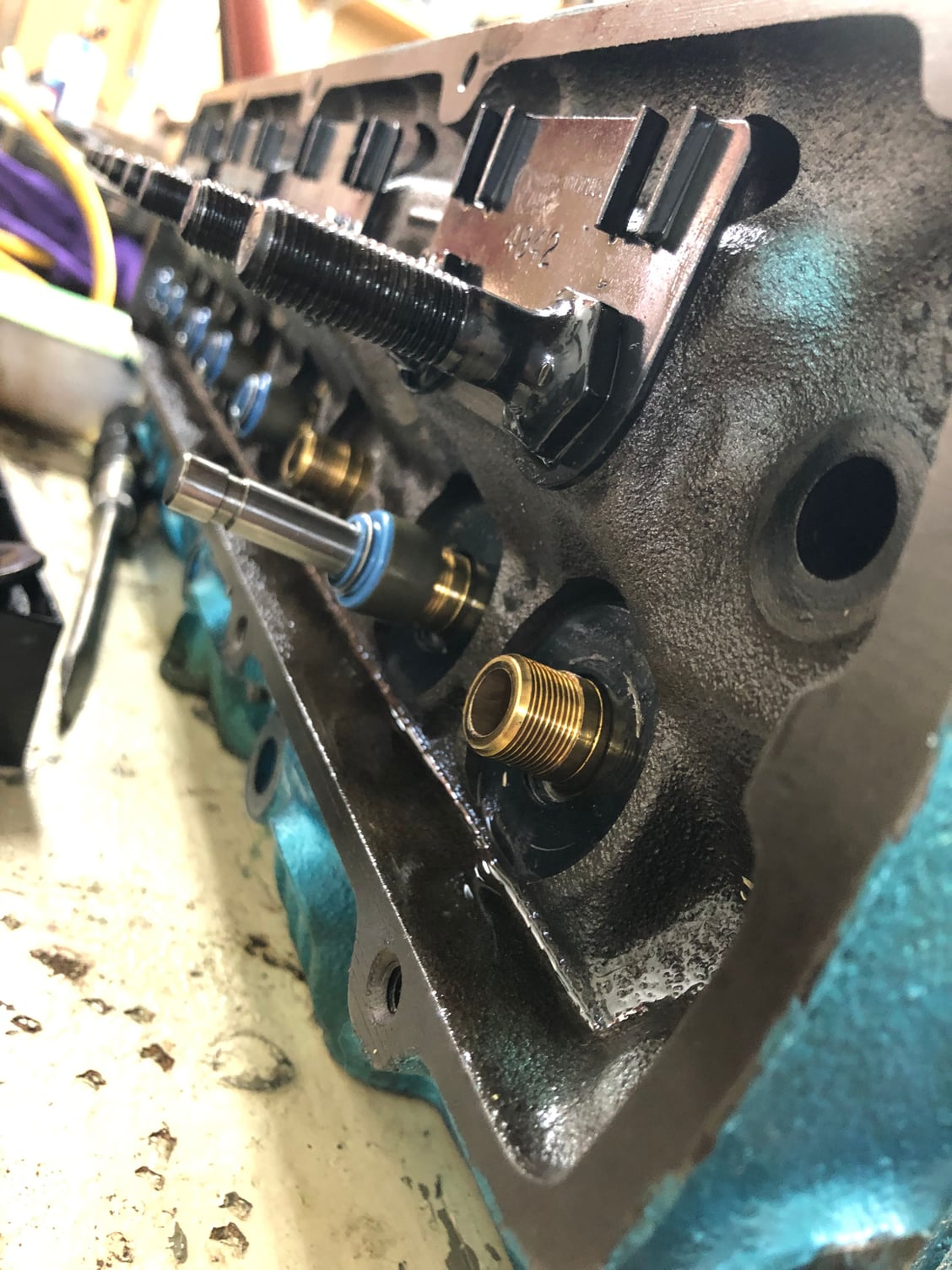

This is the passenger side head. Itís on the bench and the intake valve is out. Itís been rebuilt this fall and has about 100 miles on it

Rocker arm side of head showing the guides and seal

Intake valve. About 100 miles on this valve. Started out brand new

Intake gasket is torn from being taken off but it appears to be dry

Same intake gasket

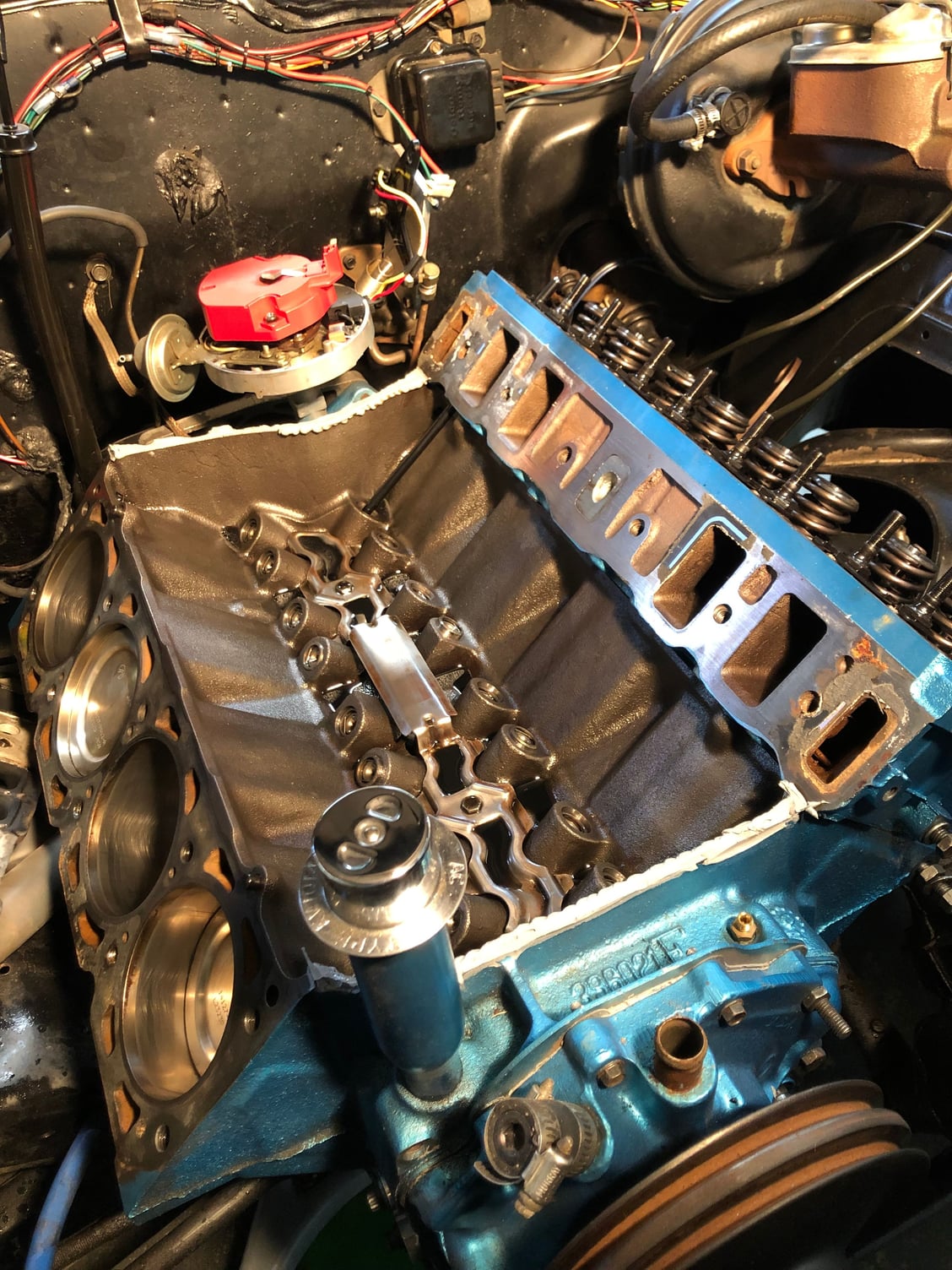

Engine bay. Driver side head still on engine

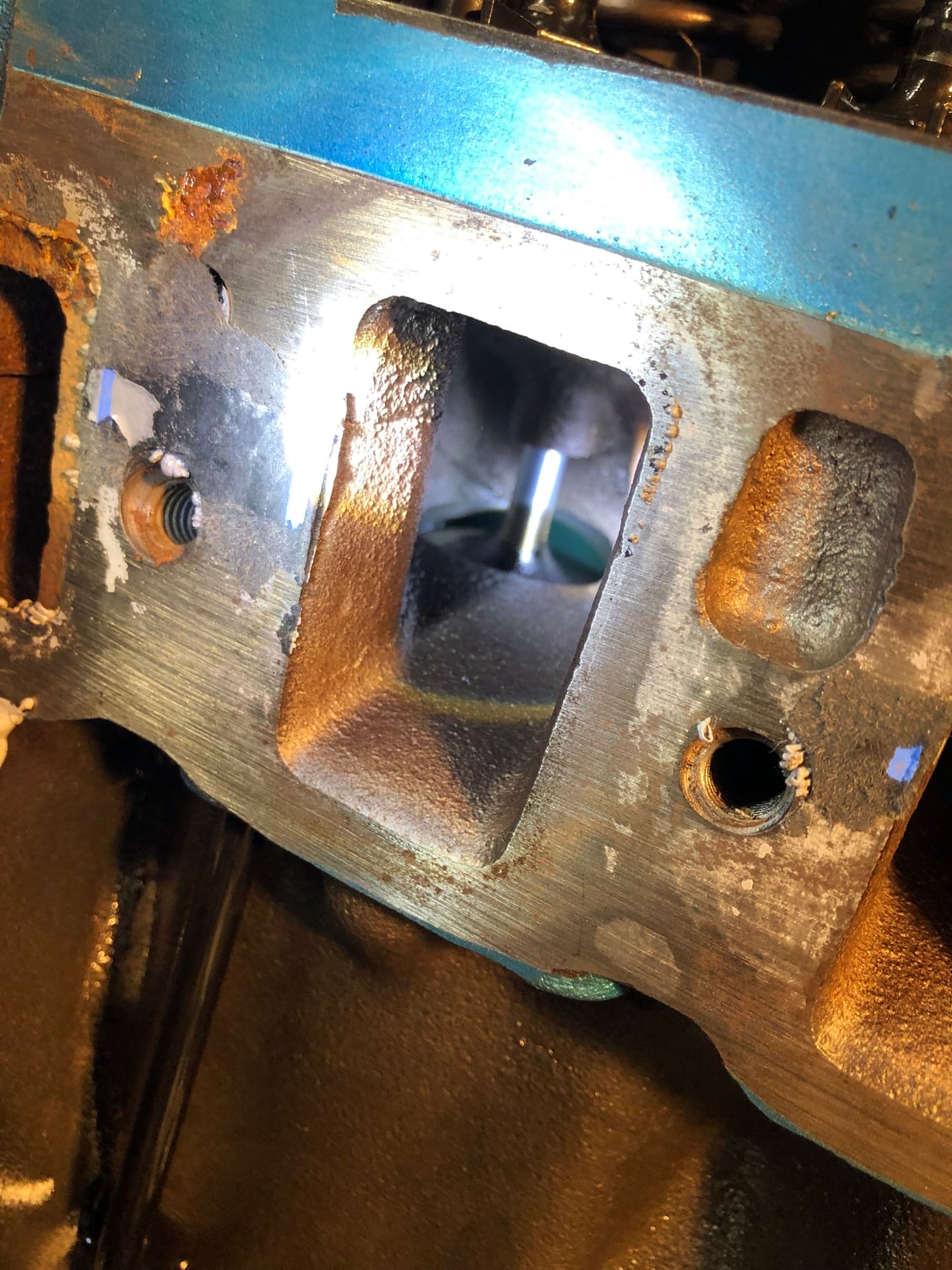

Number 8 cylinder intake valve. It looks like coolant but itís oil. Shows green on the pic for some reason

#19

I figured a pic is worth a thousand words. Maybe someone can shed some light on why this thing is sucking oil

For what itís worth Iím not re using these heads. I bought aluminum heads. I just donít want this happening again

For what itís worth Iím not re using these heads. I bought aluminum heads. I just donít want this happening again

#20

Sometimes sealing up the top half of the engine can cause the rings to loose their seal. This may not be what happened to you but I've heard of it before. Honda specifically mentions when changing head gaskets DO NOT do a valve job on high mileage engines. Maybe some professional engine builders can shed some light on your problem. Good luck.

#22

Do the stems and guides look worn/scuffed on the rocker pressure sure side? The fulcrum angle could be off due to deck height and pushrod length. Hows the contact pattern on the valve tip look? Or is there not enough miles to show this?

The spring witness mark in the front spring pocket looks off centered as does the guide? How does the seat and valve head machined surfaces look? Any evidence of misalignment?

IMO The symptom as you describe it(sitting then puddling) is conducive to bad stem/guide/seal areas. If it was pulling it in from the crankcase it would/could look like a bug fogger and use quarts of oil.

To review: this oil puddling is observed on all intake valves? If yes the guides need to be inspected closely. Prop the heads up so the spring pockets are level then fill the pockets with PB, 3 &1 or 10 weight oil etc...see if the oil wicks past the guides. I've seen that before.

The spring witness mark in the front spring pocket looks off centered as does the guide? How does the seat and valve head machined surfaces look? Any evidence of misalignment?

IMO The symptom as you describe it(sitting then puddling) is conducive to bad stem/guide/seal areas. If it was pulling it in from the crankcase it would/could look like a bug fogger and use quarts of oil.

To review: this oil puddling is observed on all intake valves? If yes the guides need to be inspected closely. Prop the heads up so the spring pockets are level then fill the pockets with PB, 3 &1 or 10 weight oil etc...see if the oil wicks past the guides. I've seen that before.

#23

@george landis the engine is a 455 with E heads not a 400E

@droldsmorland im using adjustable valve train with 9.625 length pushrods that are centered nicely on the valve tips

judging by eye only the guides look centered and the engine only has about 100 miles since the heads were rebuilt using new valves both I and E The guides and seals are new also

i made up a makeshift cup over the guide seal with the intake valve in place and poured engine oil in the makeshift cup and let it sit over night. It was a bench test with the head off the engine and it didn’t leak down

i was talking with mark cutlasefi and he thinks I may have installed the second compression oil scraper ring upside down. So I’ll be pulling the motor and checking the rings. The remeber the seconds rings (Hastings) being vague as to which way they installed and I may very well have installed them upside down so they are scraping up not down

I will keep us updated

thank you for everyone’s suggestions

@droldsmorland im using adjustable valve train with 9.625 length pushrods that are centered nicely on the valve tips

judging by eye only the guides look centered and the engine only has about 100 miles since the heads were rebuilt using new valves both I and E The guides and seals are new also

i made up a makeshift cup over the guide seal with the intake valve in place and poured engine oil in the makeshift cup and let it sit over night. It was a bench test with the head off the engine and it didn’t leak down

i was talking with mark cutlasefi and he thinks I may have installed the second compression oil scraper ring upside down. So I’ll be pulling the motor and checking the rings. The remeber the seconds rings (Hastings) being vague as to which way they installed and I may very well have installed them upside down so they are scraping up not down

I will keep us updated

thank you for everyone’s suggestions

#25

Iíve been emailing with cutlassefi and he suggested that the second rings may be installed wrong. I popped one piston and the rings are installed properly. I think Iím just going to install the aluminum heads and hope for the best I donít know what else could cause the oil to pool on the intake valves like that

Thanks for all the suggestions Iíll update my findings in a little but after I get this motor put back together

Thanks for all the suggestions Iíll update my findings in a little but after I get this motor put back together

Thread

Thread Starter

Forum

Replies

Last Post