Stainless Steel bolt Torque vs stock bolts

#1

Stainless Steel bolt Torque vs stock bolts

Good morning fellow grease monkeys! I am going to use 304 Stainless Steel bolts for my aluminum intake on 455. The question I have is normal torque specs are 35ft lbs and when using 3/8 stainless the max torque is 20ft lbs. That seems light but I understand that SS has more tensile strength so makes sense. Just wanted to see if others have used SS on their aluminum intake and what torque you used.

Thanks!

Thanks!

#2

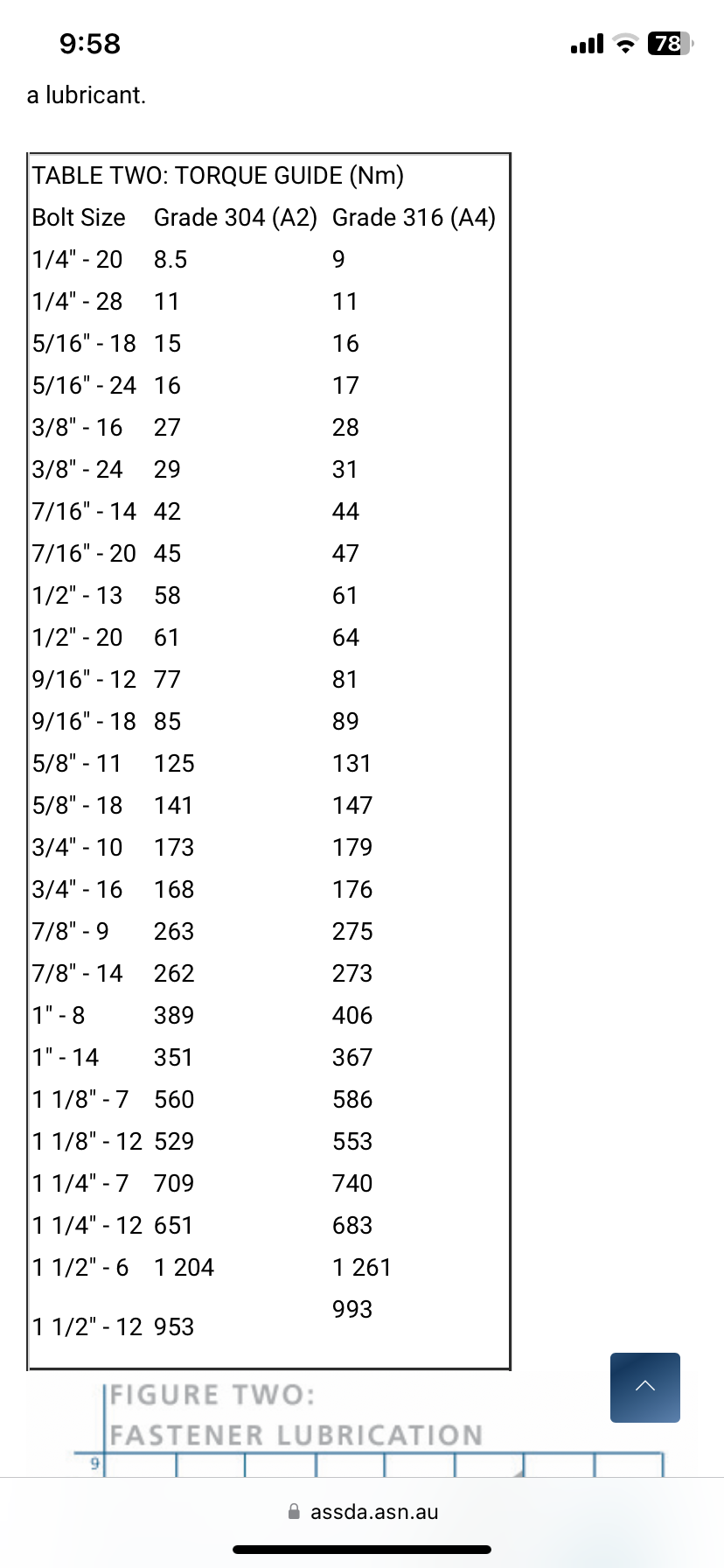

Who's telling you that the torque is only 20 ft-lbs?

Understand that the important measurement is clamping force on the joint. Torque is a poor way to gauge clamping force, but it is unfortunately the only practical way to gauge this for a blind fastener like an intake bolt. Unfortunately the relationship between torque and clamping force varies with bolt material, thread friction, washer friction, and even the length of the bolt.

The material property that matters is stiffness, and both stainless and plain steel have about the same stiffness. Strength of the bolt can vary all over the map for stainless, but unless you actually start yielding the bolt, it won't change clamping force.

400 series stainless have the best corrosion resistance but the poorest strength - around 65,000 psi tensile, which is not a lot better than aerospace-grade aluminum.

304 and 316 series have about 85,000 - 95,000 psi tensile, which is a little worse than a Grade 5 steel bolt (105,000 psi)

High-strength stainless have 160,000-200,000 psi tensile, which is substantially stronger than Grade 8 (120,000 psi)

Understand that the important measurement is clamping force on the joint. Torque is a poor way to gauge clamping force, but it is unfortunately the only practical way to gauge this for a blind fastener like an intake bolt. Unfortunately the relationship between torque and clamping force varies with bolt material, thread friction, washer friction, and even the length of the bolt.

The material property that matters is stiffness, and both stainless and plain steel have about the same stiffness. Strength of the bolt can vary all over the map for stainless, but unless you actually start yielding the bolt, it won't change clamping force.

400 series stainless have the best corrosion resistance but the poorest strength - around 65,000 psi tensile, which is not a lot better than aerospace-grade aluminum.

304 and 316 series have about 85,000 - 95,000 psi tensile, which is a little worse than a Grade 5 steel bolt (105,000 psi)

High-strength stainless have 160,000-200,000 psi tensile, which is substantially stronger than Grade 8 (120,000 psi)

#3

#6

18-8 is a 304 series stainless, with ultimate tensile strength in the 80,000-90,000 psi range. Grade 2 bolts are 60,000-75,000 psi. Grade 5 are 105,000 psi.

#8

Yes, the reason you are being told to lower torque is not because it's stainless, but because they want you to use anti-seize. May want to use gasket sealer if going into a water jacket.

#9

#11

Unless you can find high-strength SS ($$$) I would not employ standard low-strength SS 18/8 or 3 series fasteners to an intake. SS has a propensity to gall due to the nickel content, even with a liberal application of nuclear-grade nickel antiseze. Why do you think nobody makes intake bolt kits from SS.

Chrome NON-chineasium 12-point grade 5s are a better choice IMO if you need eye candy.

Always retorque after a few heat cycles.

Industry standard is back off 10% on a dry spec that has had lubricant added. That's less 3.5lb/ft or 31.5lb/ft...not 25lb/ft.

Chrome NON-chineasium 12-point grade 5s are a better choice IMO if you need eye candy.

Always retorque after a few heat cycles.

Industry standard is back off 10% on a dry spec that has had lubricant added. That's less 3.5lb/ft or 31.5lb/ft...not 25lb/ft.

#13

#14

#15

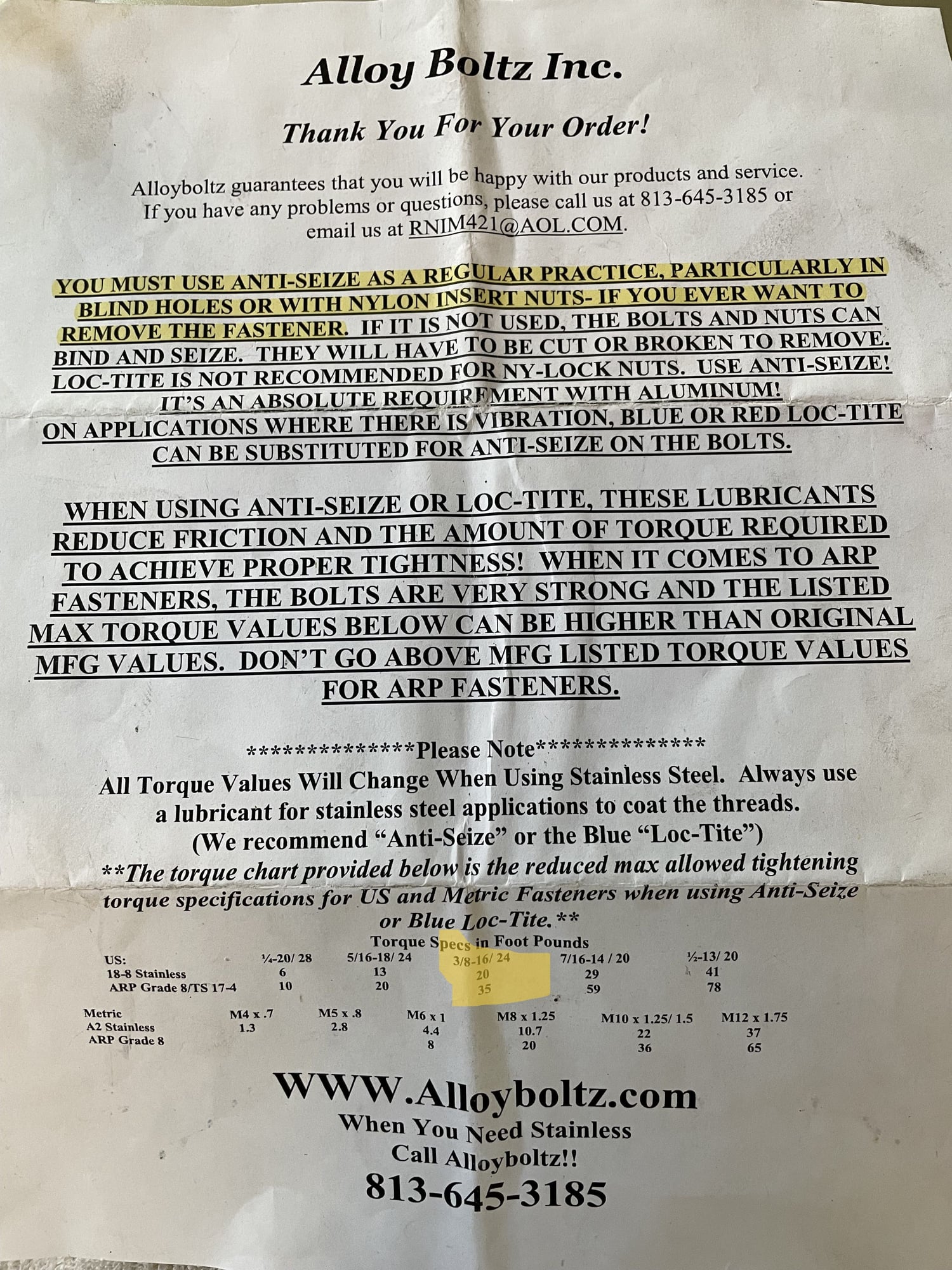

Ok. Help me out then- with factory lubricated hardware the torque spec is 35 ft-lbs. With stainless steel lubricated bolts the spec drops to 20?

This makes no sense. Is the bolt supplier recomending 20 ft-lbs because they know the bolts will snap at the proper spec?

#16

I have no explanation for the lower torque. As I noted above, the difference in strength isn't great enough to warrant the reduction. Stiffness and bolt stretch will be the same for both materials. All the lower torque will do is provide less preload on the gasket, which wouldn't be my first choice.

#17

I appreciate all the input from everyone. I spoke with Alloy Boltz and he said they have sold thousands of engine kits and has never had a problem in 20+ years. You must use anti-seize and use the reduced torque. I am moving forward with it and will let you know if there is a problem.

#18

you have three different materials in contact with each other. I would go around and do a re torque after engine has cooled.

in the end..you will ultimately have less clamping forces between the intake and head using the 18.8 stainless

here’s a hint when using one of the stainless bolts kits. the ones customers have asked me to use, don’t have big enough or thick enough washers to completely cover the big holes in an Olds intake…they tend to get sucked down into the hole

Last edited by CANADIANOLDS; November 20th, 2023 at 07:12 AM.

#20

304 stainless: yield strength 30 ksi with tensile strength 75 ksi

Grade 2 bolts: yield strength 57 ksi with tensile strength 74 ksi

In reality, most 300 series stainless fasteners are not made to any sort of controlling spec for yield strength, which makes them risky. One example of a reputable spec is an A193 Grade B8 (NOT other B-numbers). Unless you get the hardware from a reputable source (McMaster, Fastenal, etc) you may have no idea what strength spec the fasteners meet.

You need to use the lower torque spec with 18-8 stainless fasteners. They have nowhere near the clamping load of carbon steel fasteners.

#22

I appreciate all the input from everyone. I spoke with Alloy Boltz and he said they have sold thousands of engine kits and has never had a problem in 20+ years. You must use anti-seize and use the reduced torque. I am moving forward with it and will let you know if there is a problem.

#23

Using tensile strength is misleading, as torque values are based off yield, unless you are designing a one time use fastener.

304 stainless: yield strength 30 ksi with tensile strength 75 ksi

Grade 2 bolts: yield strength 57 ksi with tensile strength 74 ksi

In reality, most 300 series stainless fasteners are not made to any sort of controlling spec for yield strength, which makes them risky. One example of a reputable spec is an A193 Grade B8 (NOT other B-numbers). Unless you get the hardware from a reputable source (McMaster, Fastenal, etc) you may have no idea what strength spec the fasteners meet.

You need to use the lower torque spec with 18-8 stainless fasteners. They have nowhere near the clamping load of carbon steel fasteners.

304 stainless: yield strength 30 ksi with tensile strength 75 ksi

Grade 2 bolts: yield strength 57 ksi with tensile strength 74 ksi

In reality, most 300 series stainless fasteners are not made to any sort of controlling spec for yield strength, which makes them risky. One example of a reputable spec is an A193 Grade B8 (NOT other B-numbers). Unless you get the hardware from a reputable source (McMaster, Fastenal, etc) you may have no idea what strength spec the fasteners meet.

You need to use the lower torque spec with 18-8 stainless fasteners. They have nowhere near the clamping load of carbon steel fasteners.

Last edited by CANADIANOLDS; November 20th, 2023 at 02:41 PM.

#24

he did his own research on that and found the same thing.

the only exception I know of is some ARP stainless fasteners that have a much higher yield and tensile rating..that’s because some of theirs are forged. they call theirs the “300” series. They are not equivalent to standard 304 etc bolts

#27

Let us know how the install goes. Are you going to use the turkey tray gasket? At the very least, most folks ditch the lifter valley seals and use Right Stuff gasket maker.

https://www.oreillyauto.com/detail/c...ker/pery/85224

https://www.oreillyauto.com/detail/c...ker/pery/85224

#28

#29

That being said the fact that he is specifying anti seize probably has a lot to do with the torque spec. A torque wrench basically measures friction. If you put a bolt in a part dry and torque it to 30 ft lbs and mark it, then take it back out and put antiseize on it and torque it again I would bet it will turn as much as an additional 1/4 turn which stretches the bolt more.

#30

I've been using polished stainless bolts on many of my projects, and friend's, too. Never had any issues with them. Some have been on the road for 20+ years.

Intake, exhaust, timing cover, oil pan, etc. Still use grade 8 where necessary, though: bellhousing, vibration damper, etc.

Intake, exhaust, timing cover, oil pan, etc. Still use grade 8 where necessary, though: bellhousing, vibration damper, etc.

#31

Sorry, you are right BillK.

Thanks Chopolds, I have been waiting for someone to chime in that have actually used SS on their intake that could give feedback. For sure will use grade 8 if needed.

Thanks again everyone!

Thanks Chopolds, I have been waiting for someone to chime in that have actually used SS on their intake that could give feedback. For sure will use grade 8 if needed.

Thanks again everyone!

Thread

Thread Starter

Forum

Replies

Last Post

jensenracing77

General Discussion

10

October 3rd, 2020 07:09 AM