Transmission Rebuild

#81

There is no down side to dual feeding the directs. If the trans is apart, I internally dual feed by removing the center seal, leaving off one sealing ring on the stator support, and blocking the reverse feed in the case with a 3/8 set screw. If you machine the direct piston for a 5th friction, with the addition of the dual feed, added pressure of the pressure regulator spring, you have added enough surface area and clamping force that hard parts will break before the frictions will slip. The accumulator piston in the valve body is for a 2-3 upshift. The accumulator on the side of the case is for the 1-2 upshift, it really should remain functional, the intermediate sprag will be more reliable. I would need to refer to my notes, I think the orange spring was used in the factory high performance applications.

I know this thread involves a th350, but referring to the 400 upgrades there are some better methods to improve the shifts. Instead of grinding the 2-3 accumulator piston and flipping it over, just block the feed hole to the back side of the piston. As for the 1-2 accumulator spring in the rear servo, the yellow spring was used in the factory performance applications. The orange spring used in the 4L80 will also fit.

I know this thread involves a th350, but referring to the 400 upgrades there are some better methods to improve the shifts. Instead of grinding the 2-3 accumulator piston and flipping it over, just block the feed hole to the back side of the piston. As for the 1-2 accumulator spring in the rear servo, the yellow spring was used in the factory performance applications. The orange spring used in the 4L80 will also fit.

#83

The shift firmness has a lot to do with the torque converter. With a lose converter, the shift is hardly noticeable. Stand on the loud pedal, the shift gets much firmer. And with the th350/400 trans, there is no sprag on the 2-3 shift to tear up. And the factory omitted the accumulator spring on the heavy duty trucks and high performance applications.

#84

Well i did what i was proposing, since i dont have my engine, STILL on machineries, i tore my trans down a bit since i have spare seals.

Took pump off, valve-train to bits. Transgo separator plate off. Drill two spot-welds off from it( they both locate to pump suction area), throw transfer-plate to trash, and removed the needed seals from direct and stator. Transgo-plate already blocks the reverse-passage.

Pretty much not the idea of shift-kit. When i bought all my parts, i didnt know you could do it internally, actually didnt even know about whole dual-feeding. After searching more, the less great idea it was to have possible leak in form of transfer-plate. So, now i dont have that transfer plate anymore, but all the parts that come in reprpgramming kit are assembled on valve-body, and orifice sizes are how transgo made them on their separator plate.

And im a bit happier knowing that transfer-plate aint never going to leak since its eliminated.

Took pump off, valve-train to bits. Transgo separator plate off. Drill two spot-welds off from it( they both locate to pump suction area), throw transfer-plate to trash, and removed the needed seals from direct and stator. Transgo-plate already blocks the reverse-passage.

Pretty much not the idea of shift-kit. When i bought all my parts, i didnt know you could do it internally, actually didnt even know about whole dual-feeding. After searching more, the less great idea it was to have possible leak in form of transfer-plate. So, now i dont have that transfer plate anymore, but all the parts that come in reprpgramming kit are assembled on valve-body, and orifice sizes are how transgo made them on their separator plate.

And im a bit happier knowing that transfer-plate aint never going to leak since its eliminated.

Last edited by Inline; April 3rd, 2019 at 09:03 AM.

#85

I somehow managed to post the following in the wrong thread, so here it is again in the right one:

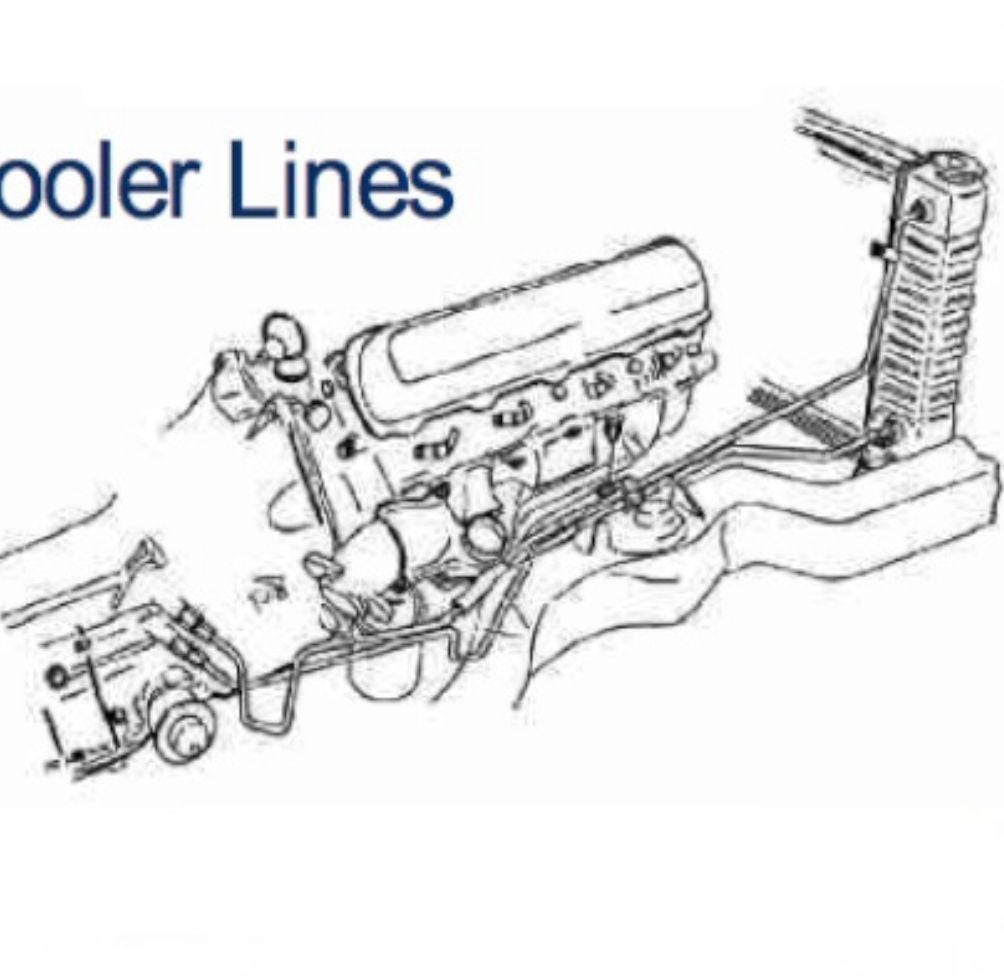

Hi guys, can someone confirm the correct connection points for the cooler lines? The one that comes off the upper radiator connection and takes the immediate down turn - does it connect at the upper or lower fitting on the transmission? I should have taken a picture before I took them off. Thanks.

Hi guys, can someone confirm the correct connection points for the cooler lines? The one that comes off the upper radiator connection and takes the immediate down turn - does it connect at the upper or lower fitting on the transmission? I should have taken a picture before I took them off. Thanks.

#87

Thanks! Looks like I guessed right, upper to upper and lower to lower. I have them close, just have to make a few final adjustments and that is another thing off the list.

One other thing more to just ease the nerves - if a torque converter wasn't seated all the way, when going to install the transmission it would be right up against the flywheel probably to the point where the trans wouldn't mount to the engine right? Mine was basically right up against the case to where I couldn't even fit my fingers in between it and the case and the distance to the flywheel was just under 3/8", within the 1/8" min to 3/8" max listed. I went a bought some wahsers to get it closer to the 1/8" mark just to be safe. I just cringe at the though of it not being seated in the pump right and all of this having to be redone, lol.

One other thing more to just ease the nerves - if a torque converter wasn't seated all the way, when going to install the transmission it would be right up against the flywheel probably to the point where the trans wouldn't mount to the engine right? Mine was basically right up against the case to where I couldn't even fit my fingers in between it and the case and the distance to the flywheel was just under 3/8", within the 1/8" min to 3/8" max listed. I went a bought some wahsers to get it closer to the 1/8" mark just to be safe. I just cringe at the though of it not being seated in the pump right and all of this having to be redone, lol.

#88

If the converter will spin with the trans bellhousing duly tightened to the engine block, your good. As long as there is some clearance between the flex plate and the converter your good. If the converter is wedged tight, either itís habging up on the pilot hub in the crank, the converter isnít seated, or some other installation mistake. You will almost definitely break the pump, damage the converter, or possibly destroy the crank thrust bearing.

#89

Perfect, then I should be good. I was sure it was on right before I put it back under the car. I felt and heard the 3 clunks as it went in and was seated to where there was almost no room between it and the bottom of the case. I had a piece bolted on to hold it in place, but after it was under the car I had to take it off again. If the car was probably half a foot higher this would have been a lot easier, but there wasn't enough room to get the trans on the jack and roll it under the car, and now with gravity working against me, getting it back up on the jack while under the car was not going well so taking the converter off helped shed some weight and make it easier to work with. That will be filed under lesson learned for next time.

#90

Hi guys,

That electrical connection on the passenger side of the transmission right under where the cooler lines connect - how critical is that, and what does it do? From what I have found it just adjusts the timing slightly at highway speeds, just not sure if that is entirely right and if it were not connected or not working what would happen?

I was able to open up the doors finally with some nice weather and with all the extra light I noticed that one of the wires to it appears to have been pulled out of the plastic piece. I am just wondering if I should try to find another plastic connector or will be fine without it.

That electrical connection on the passenger side of the transmission right under where the cooler lines connect - how critical is that, and what does it do? From what I have found it just adjusts the timing slightly at highway speeds, just not sure if that is entirely right and if it were not connected or not working what would happen?

I was able to open up the doors finally with some nice weather and with all the extra light I noticed that one of the wires to it appears to have been pulled out of the plastic piece. I am just wondering if I should try to find another plastic connector or will be fine without it.

#91

Hi guys,

I think all the work is done and it is hopefully ready to fire up. My question this time is about a safe transmission fluid running level while idling in park. I have 1 quart in the converter and based on what I can find online and in my book was going to add 4-5 more quarts before starting it. Apparently then with it running you would go add more until at the low end of the dipstick, but in my case with the new distributor I am likely going to be occupied with the timing and getting it to run half decent and checking everything for leaks first so it may be a little bit before I get to working on the trans fluid level.

To me, 5-6 quarts of transmission fluid if it is just sitting and idling should be fine, but thought some more informed opinions would be best. I would hate to ruin my first rebuild before it is ever put in gear, lol.

Thanks guys

I think all the work is done and it is hopefully ready to fire up. My question this time is about a safe transmission fluid running level while idling in park. I have 1 quart in the converter and based on what I can find online and in my book was going to add 4-5 more quarts before starting it. Apparently then with it running you would go add more until at the low end of the dipstick, but in my case with the new distributor I am likely going to be occupied with the timing and getting it to run half decent and checking everything for leaks first so it may be a little bit before I get to working on the trans fluid level.

To me, 5-6 quarts of transmission fluid if it is just sitting and idling should be fine, but thought some more informed opinions would be best. I would hate to ruin my first rebuild before it is ever put in gear, lol.

Thanks guys

#92

If itís a fresh rebuild, with a new converter, I bet it will take 8-10 quarts to completely fill it. If you hear the pump whining, add some more fluid. As long as the trans is in park, running it a LITTLE low shouldnít hurt anytime.

#93

Thanks. The common opinion online seems to be 10-12 on a rebuild with a new converter, or rebuilt converter in my case. I have a little over 6 in there right now. Maybe I will throw another quart or so in and listen for the pump like you say. I should only need a few minutes to get it to where it is running decent enough that it can drive so I can get the trans filled up more.

#94

Hi guys,

That electrical connection on the passenger side of the transmission right under where the cooler lines connect - how critical is that, and what does it do? From what I have found it just adjusts the timing slightly at highway speeds, just not sure if that is entirely right and if it were not connected or not working what would happen?

I was able to open up the doors finally with some nice weather and with all the extra light I noticed that one of the wires to it appears to have been pulled out of the plastic piece. I am just wondering if I should try to find another plastic connector or will be fine without it.

That electrical connection on the passenger side of the transmission right under where the cooler lines connect - how critical is that, and what does it do? From what I have found it just adjusts the timing slightly at highway speeds, just not sure if that is entirely right and if it were not connected or not working what would happen?

I was able to open up the doors finally with some nice weather and with all the extra light I noticed that one of the wires to it appears to have been pulled out of the plastic piece. I am just wondering if I should try to find another plastic connector or will be fine without it.

#95

It looks like it is all good now. Nice and dry underneath, I put in about 9.8 quarts total after it was warmed up and driven around a bit, and factoring in the bit of fluid used during the build I should be right at 10 quarts or so. I will let it cool down and warm it up to check it one more time tomorrow.

Most importantly, it hit third gear, so that is a huge relief for me. The only thing I noticed is it seems to shift into third a little later than I would have thought, but I like where it shifts into second. It hit second at about 17 MPH, but I didn't notice exactly where it hit third. I will note that tomorrow. By adjusting that screw on the modulator it will change both shift points, correct? It would be nice if I could just change third but even if second changes a little that is probably OK.

Thanks to everyone for helping me along the way. I learned a lot and saved a lot of money!

Most importantly, it hit third gear, so that is a huge relief for me. The only thing I noticed is it seems to shift into third a little later than I would have thought, but I like where it shifts into second. It hit second at about 17 MPH, but I didn't notice exactly where it hit third. I will note that tomorrow. By adjusting that screw on the modulator it will change both shift points, correct? It would be nice if I could just change third but even if second changes a little that is probably OK.

Thanks to everyone for helping me along the way. I learned a lot and saved a lot of money!

#96

Turning the screw in the modulator will change shift points. About 2-4 mph is about all the adjustment you will get. Turning the screw in raises the shift point, backing it out lowers it. Glad to hear you have all 3 gears

Thread

Thread Starter

Forum

Replies

Last Post

OldsManNJ

Transmission

4

November 22nd, 2012 07:48 AM