Milling intake to match heads

#1

Milling intake to match heads

Ok forgive me if this has already been answered before. I did a search and couldn't find any old threads answering my question. I'm thinking about purchasing a set of Pro Comp heads from Bernard for my sbo.I have a 7111 intake on my motor now. If I take the heads to a machinist and have him mill the heads for a smaller combustion chamber, can he mill the intake to match without my short block in his shop or will I need to cart my block over there as well? I'm going to call him on Monday and ask as well but I figured I'd ask on here before then.

#2

https://classicoldsmobile.com/forums...ads-060-a.html

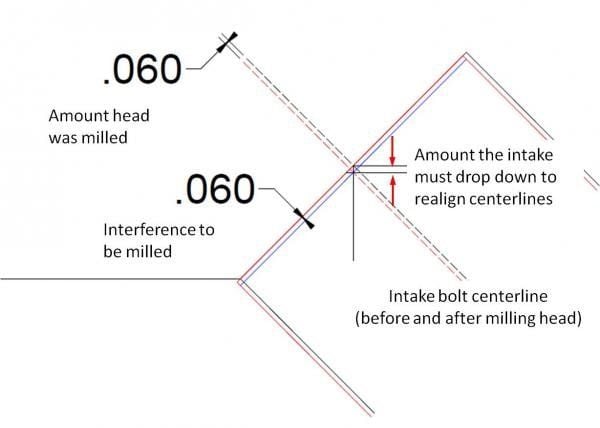

Bottom line is that unlike Chevy motors, the Olds intake flange is exactly 90 degrees to the deck surface. For small cuts, no milling is needed. For large cuts, milling the same amount off the intake restores the intake bolt and port centerlines to their original orientations.

#4

You can't mill a lot from the intake surface because of the proximity of the valve cover bolts. You can take around .010-.030" off. You can also get the intake manifold milled, and use RTV instead of the end rubber gaskets.

#5

I think he was asking about milling the intake manifold.

#6

My #6 heads were milled to bring the chambers to 55 CC. I bought them this way and according to my calculations that is close to .080" cut. The intake face was cut, it is a tight fit with my RPM and turkey tray and Felpro head gaskets but it does fit. I think there was more than .030" cut done to the intake surface. I like that I can buy any intake to fit, another big turn off buying aluminum heads for a small block. Nearly any SBO combo would need the intake cut a good amount. Thanks Joe, that makes it extremely simple for my future plans.

Thread

Thread Starter

Forum

Replies

Last Post

Joel

Big Blocks

33

April 26th, 2017 01:37 PM

RAMBOW

Big Blocks

17

July 31st, 2011 01:59 AM