Lower End Support

#1

Lower End Support

Well we've got a couple good threads going about cylinder heads, and seeing how it's winter time, I think we need a good girdle thread. Yeah maybe I'm stirring the pot a little, but I really do have some questions, and Classic Olds really is pretty new to the high performance racing end of Oldsmobiles. My questions are:

1) What type of lower end support are any of you using?

2) What size engine and HP level are you at?

3) Have you experienced any bearing or crank failure with your set up?

4) At what level do you think a person needs to consider upgrading their lower end support?

5) How much did you invest in your complete bottom end with all parts and machine work?

6) Do you wish you had gone a different route?

1) What type of lower end support are any of you using?

2) What size engine and HP level are you at?

3) Have you experienced any bearing or crank failure with your set up?

4) At what level do you think a person needs to consider upgrading their lower end support?

5) How much did you invest in your complete bottom end with all parts and machine work?

6) Do you wish you had gone a different route?

#2

My engine

In my BB I went with 1/2" steel straps, ARP studs, heavy TRW pistons, an "N" crank, reworked stock steel rods, West Coast Innovators balancer, and a heavy Mondello inertia flexplate. The rotating assembly was balanced. This engine has been built over a very long time frame. I still need to get to the track. I think my combination should be good for close to 500 HP. The main stud strap kit cost me $98 back in '96. With parts and machine work I have close to $2000 into my rotating assembly. These parts are very heavy, and the straps are probably the cheapest upgrade for bottom end support. Most of the top Olds builders do not feel they offer much of an upgrade. I was told they could support 600HP. The installation instructions tell you to machine .500 inch off the main caps when using a windage tray. We did not do that with my caps. Joe Mondello explained it to me why that was necessary but I don't think I could do a very good job explaining it myself. apparently by machining that much off the cap it becomes more flexible, but then by adding the harder and stiffer steel strap it makes the cap hold it's shape better and causes less bearing wear. I did not do this to my caps, so basically my machinist did not install them correctly and they are probably doing nothing for me. Well I thought we could all get a laugh from this and I know if I had it all to do again, I would have much lighter rotating assembly and a full girdle. The next engine I build will be shooting for over 700 HP naturally aspirated.

#3

I have never built a high HP Olds engine, but IMO better to spend the $ on quality pistons and rods, then use proper clearances and good machine work. Balancing is a given on any engine, again, IMO. This will be fine for the vast majority of guys. Again, no experience with stuff over 500 HP

#4

Options

Yeah Jim, I agree that it makes no sense to pay big money for a girdle and then cheap out on the rest of the parts. Bill Trovato has been pushing the limits of the BB Olds for a while. He's pushed the stock cranks up to 700 HP and said they flex a whole lot. It has been said that the SB - block is stronger than the BB - block. You sure don't here about them pulling apart at the motor mount area. Of course the 403 and later model 350s with the windowed main webs aren't as strong as the earlier stuff. Well I have some photos to share and was just going to list some lower end support options. If someone wants to chime in about the strength of each of these please do so. I have no real world experience with them so I can't comment other than here say.

1) Billet steel or Aluminum 2 bolt or 4 bolt caps. Rocket Racing, Smitty, BTR all sells different versions. Some have said that installing the 4 bolt main caps weakens the block and others have said when installed correctly using hard block filler, it is much stronger than stock. No comment from me.

RocketRacingBilletCaps.jpg

168.jpg

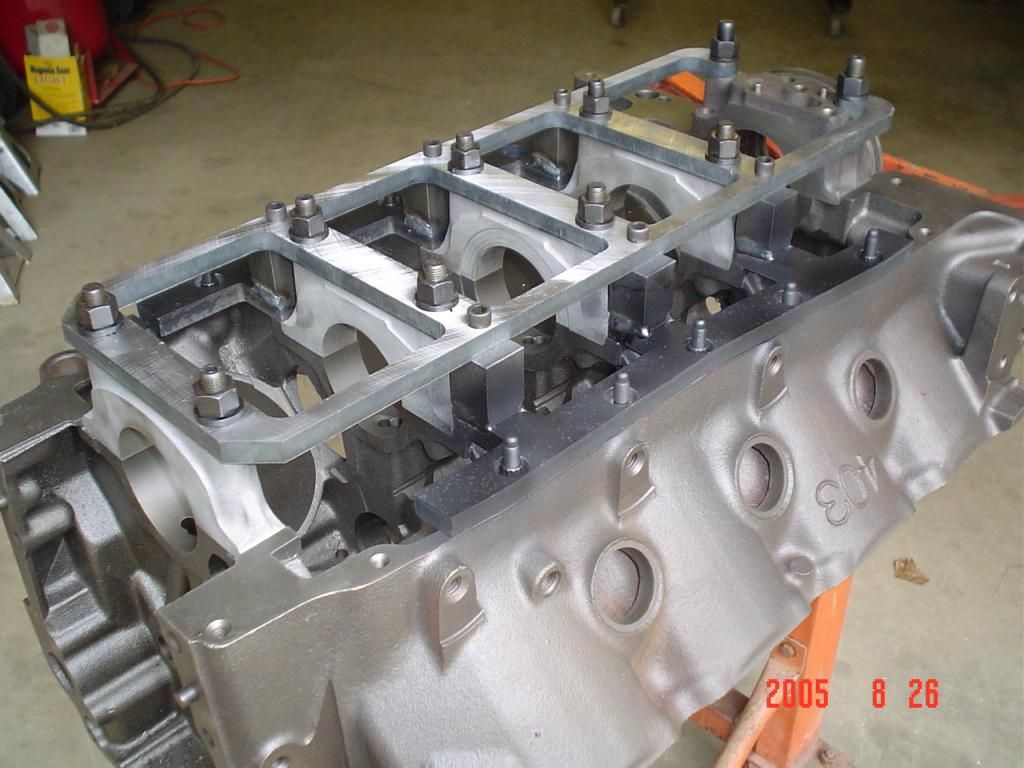

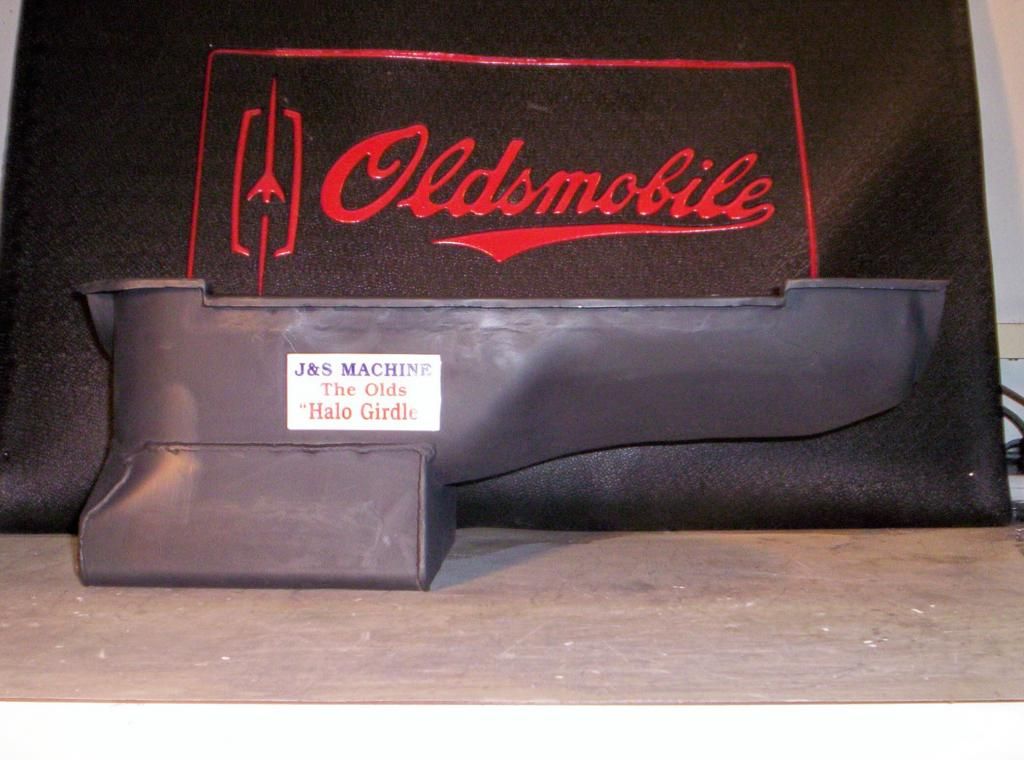

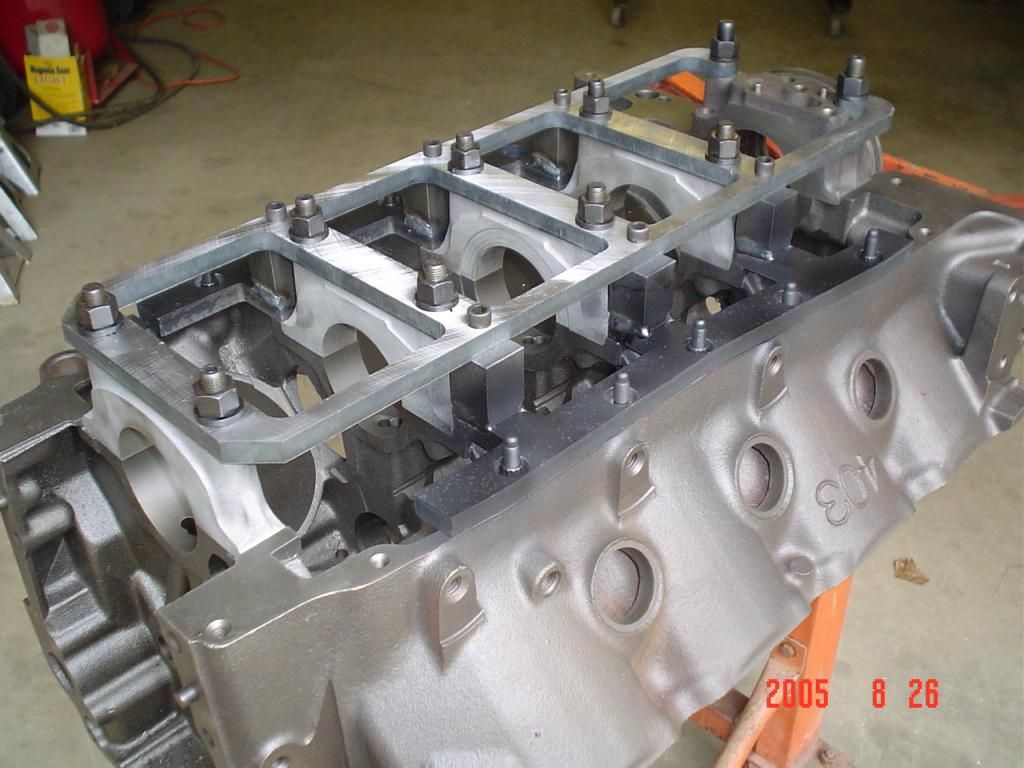

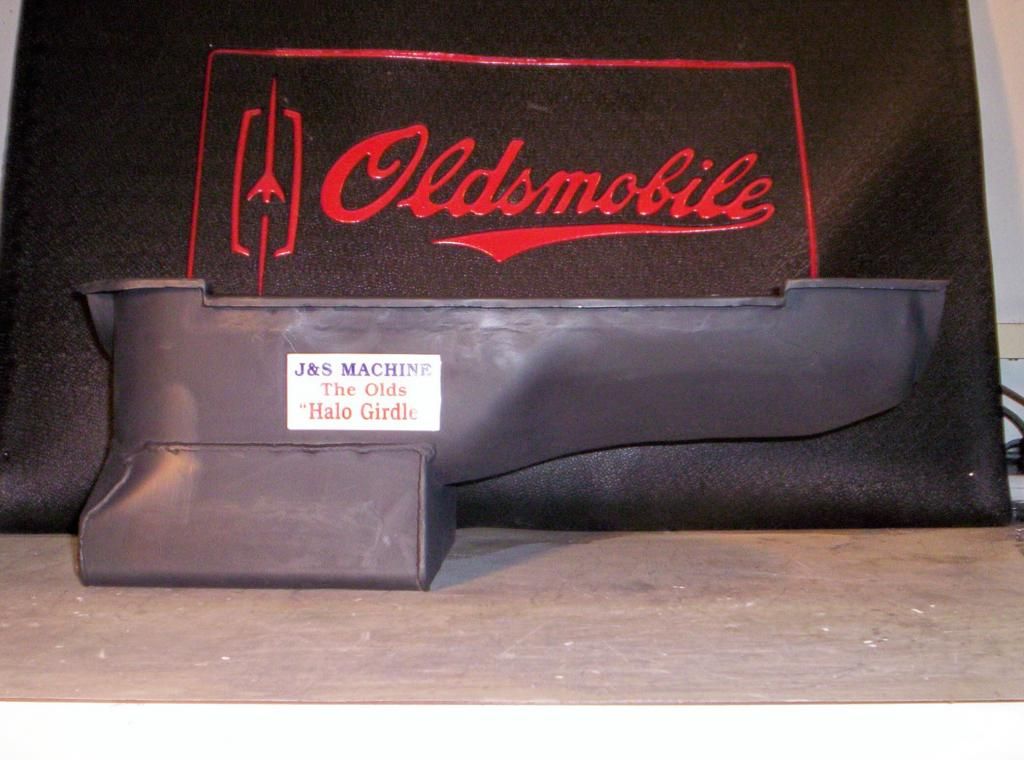

2) Next would be the "Halo" which was developed by Jim from J&S Machine. This ties all the main caps together. It requires the main caps to be machined and the block should be line honed after installation. I installed one of these with studs on a high compression 350 short block that has yet to be fired up. Jim was very good to work with. I consider this cheap insurance. It probably wasn't necessary on my 350 but I wanted something a little better than stock caps. I can't comment on the added strength because I have not done any testing. Some guys will tell you the Halo does very little to help stiffen the bottom end, but it does make a nice grab handle when your bottom end is scattered on the track.

JampSHalo.jpg

3) J&S also offers an upgrade to convert the Halo to a full blown girdle. I'm not sure what power levels this bolted together girdle is supposed to be able to handle, but it does require oil pan modification as do most girdles.

4) The solid steel girdle was made popular for Olds by Jeff Smith I believe. It is carved from a solid piece of steel or aluminum. It seems like most of the heavy hitters are running this style of a girdle. All the top Olds venders have their own version. The guys running these things are pushing their BB Olds to the limits.

BTRGirdle.jpg

5) There is another type of girdle that has been made. Rocket Racing sells a full girdle that has been welded together that does not require oil pan modification.

RocketRacingGirdle.jpg

6) Another girdle that was offered a few years back was a billet unit that also incorporated the caps. This was designed by Noel and only a hand full were made. This was a very creative design with a lot of man hours. possibly the strongest girdle made to this date. The only problem I see with this type of design is that it lowers the oil pan some. If your cross member was already tight to the pan, it could be a problem. I think all the guys that purchased these have tube chassis cars or a modified cross member.

Noelsgirdle2.jpg

7) The latest creation that I have seen come out is "The Cage" offered up by Cody and his team at Joe Mondello Racing Engines in Tennessee. This thing looks really cool and strong. It's a one piece deal made from billet aluminum and carved up on a CNC. This might be the strongest one built to date and Cody wants to test it to it's limits on his 403 race engine.

cage.jpg

Well guys that's all I've got for you. Please feel free to comment with your opinions or facts. No worries here just trying to show case some options. Venders feel free to make your sales pitch here.

1) Billet steel or Aluminum 2 bolt or 4 bolt caps. Rocket Racing, Smitty, BTR all sells different versions. Some have said that installing the 4 bolt main caps weakens the block and others have said when installed correctly using hard block filler, it is much stronger than stock. No comment from me.

RocketRacingBilletCaps.jpg

168.jpg

2) Next would be the "Halo" which was developed by Jim from J&S Machine. This ties all the main caps together. It requires the main caps to be machined and the block should be line honed after installation. I installed one of these with studs on a high compression 350 short block that has yet to be fired up. Jim was very good to work with. I consider this cheap insurance. It probably wasn't necessary on my 350 but I wanted something a little better than stock caps. I can't comment on the added strength because I have not done any testing. Some guys will tell you the Halo does very little to help stiffen the bottom end, but it does make a nice grab handle when your bottom end is scattered on the track.

JampSHalo.jpg

3) J&S also offers an upgrade to convert the Halo to a full blown girdle. I'm not sure what power levels this bolted together girdle is supposed to be able to handle, but it does require oil pan modification as do most girdles.

4) The solid steel girdle was made popular for Olds by Jeff Smith I believe. It is carved from a solid piece of steel or aluminum. It seems like most of the heavy hitters are running this style of a girdle. All the top Olds venders have their own version. The guys running these things are pushing their BB Olds to the limits.

BTRGirdle.jpg

5) There is another type of girdle that has been made. Rocket Racing sells a full girdle that has been welded together that does not require oil pan modification.

RocketRacingGirdle.jpg

6) Another girdle that was offered a few years back was a billet unit that also incorporated the caps. This was designed by Noel and only a hand full were made. This was a very creative design with a lot of man hours. possibly the strongest girdle made to this date. The only problem I see with this type of design is that it lowers the oil pan some. If your cross member was already tight to the pan, it could be a problem. I think all the guys that purchased these have tube chassis cars or a modified cross member.

Noelsgirdle2.jpg

7) The latest creation that I have seen come out is "The Cage" offered up by Cody and his team at Joe Mondello Racing Engines in Tennessee. This thing looks really cool and strong. It's a one piece deal made from billet aluminum and carved up on a CNC. This might be the strongest one built to date and Cody wants to test it to it's limits on his 403 race engine.

cage.jpg

Well guys that's all I've got for you. Please feel free to comment with your opinions or facts. No worries here just trying to show case some options. Venders feel free to make your sales pitch here.

#5

Well, here are my versions of what I think is best AND have been proven to work in Drag cars which put the most stress on the bottom end of an engine. I don't think there is any equivalent to coming up on the converter on a trans brake and letting it go at 4 or 5 grand with a dead hook and 3600# of stationary weight being shocked into motion

DSC01202.jpg

Above we have the veritable tried and true studs and main straps. When done properly with a line hone this set up is good until approximately the 550hp mark. I've had excellent success with this set up on to many engines to count.

Next is my favorite. The 4 bolt main conversion of the BBO.

DSC01419.jpg

DSC01435-1.jpg

Originated by Dave Smith out in California a long time ago. I had never seen his set up or even heard of it when I designed my version of it. They are similar yet different. He uses aluminum, I use steel, along with other minor variations. Who would of thought, two Smiths with a similar idea 30yrs and couple thousand miles apart. But with the naysayers it has been hard to get this idea widely accepted. But the proof is there that it works. After installation I do recommend at least a half fill of the block. I always do a regular fill to bottom of water pump holes, even on street machines and have no problems doing so. A stiffer block is always a good thing.

NO ONE, and I do mean NO ONE, has had a failure of a block with my version of this conversion in place. And that's with a few running it well into the 800HP range both NA and/or on N2O. The very first person to buy these caps from me to see if they worked put them in a 4000lb sled, ran a 3:73 gear, only 60' in the 1.5 range and still went mid 9s at 140+. He was running TRW pistons. At the end of the season they tore it apart and found that it had been detonating so bad that the top rings were pinched so tight they could not get them off the pistons. The bearings were fine. With a test like that I'd say this set up is almost bullet proof.

Myself and many others have been running these caps for about 10-12yrs now and no block failures or bearing problems. I have over 3500 passes on my rotating assembly. After roughly 3250 passes I did have to replace my block because of a crack in it. It happened when I had my cervical spin messed up in an accident and I didn't get to winterize the car. I had popped off the lower hose and drained the radiator but never had a chance to raise the rear of the car and get the water out of the block. All the passes on this set up have been in the mid and lower 10s. We put this set up on another friends car a year before putting mine on and he's still running it. He's been 9s with it and consistently low 10s the entire time.

Now for the latest which is what I call a Bed Plate.

DSC00744.jpg

DSC00743.jpg

Only a couple out there right now. Fairly new to market and with all the bashers it's hard to get anything new and not from NY to become popular. I think this is THEE Bullet Proof set up and definitely the most cost effective. One customer was running a cast crank, which he eventually broke, and did not hurt the block. He pulled it apart, inspected, and put in another crank. He was back racing the following weekend. I would say this piece will take anything you can throw at it on an Olds block with available cylinder heads. @ $875 it is about 1/2 the cost of the solid one piece machined units and is every bit as effective. There are a couple 403builds going together with this unit and I'm anxious to see how well they perform and live. I seriously doubt that they will have main web failures. The only draw back to this unit is the fact the pan must be modified. It's not really a big deal if you go about it the right way. As long as it is sealed up properly when installed their should be no oil leaks. While not necessary I still recommend a filled block. It's a race engine and a stiff solid block is always a good thing.

I've heard the argument that filling a block just makes it heavier. While that is true for the engine on the stand, it doesn't hold up as well when you figure out how much water your not going to have in the system due to the fill. So in all reality you only gain a few pounds with a filled block.

DSC01202.jpg

Above we have the veritable tried and true studs and main straps. When done properly with a line hone this set up is good until approximately the 550hp mark. I've had excellent success with this set up on to many engines to count.

Next is my favorite. The 4 bolt main conversion of the BBO.

DSC01419.jpg

DSC01435-1.jpg

Originated by Dave Smith out in California a long time ago. I had never seen his set up or even heard of it when I designed my version of it. They are similar yet different. He uses aluminum, I use steel, along with other minor variations. Who would of thought, two Smiths with a similar idea 30yrs and couple thousand miles apart. But with the naysayers it has been hard to get this idea widely accepted. But the proof is there that it works. After installation I do recommend at least a half fill of the block. I always do a regular fill to bottom of water pump holes, even on street machines and have no problems doing so. A stiffer block is always a good thing.

NO ONE, and I do mean NO ONE, has had a failure of a block with my version of this conversion in place. And that's with a few running it well into the 800HP range both NA and/or on N2O. The very first person to buy these caps from me to see if they worked put them in a 4000lb sled, ran a 3:73 gear, only 60' in the 1.5 range and still went mid 9s at 140+. He was running TRW pistons. At the end of the season they tore it apart and found that it had been detonating so bad that the top rings were pinched so tight they could not get them off the pistons. The bearings were fine. With a test like that I'd say this set up is almost bullet proof.

Myself and many others have been running these caps for about 10-12yrs now and no block failures or bearing problems. I have over 3500 passes on my rotating assembly. After roughly 3250 passes I did have to replace my block because of a crack in it. It happened when I had my cervical spin messed up in an accident and I didn't get to winterize the car. I had popped off the lower hose and drained the radiator but never had a chance to raise the rear of the car and get the water out of the block. All the passes on this set up have been in the mid and lower 10s. We put this set up on another friends car a year before putting mine on and he's still running it. He's been 9s with it and consistently low 10s the entire time.

Now for the latest which is what I call a Bed Plate.

DSC00744.jpg

DSC00743.jpg

Only a couple out there right now. Fairly new to market and with all the bashers it's hard to get anything new and not from NY to become popular. I think this is THEE Bullet Proof set up and definitely the most cost effective. One customer was running a cast crank, which he eventually broke, and did not hurt the block. He pulled it apart, inspected, and put in another crank. He was back racing the following weekend. I would say this piece will take anything you can throw at it on an Olds block with available cylinder heads. @ $875 it is about 1/2 the cost of the solid one piece machined units and is every bit as effective. There are a couple 403builds going together with this unit and I'm anxious to see how well they perform and live. I seriously doubt that they will have main web failures. The only draw back to this unit is the fact the pan must be modified. It's not really a big deal if you go about it the right way. As long as it is sealed up properly when installed their should be no oil leaks. While not necessary I still recommend a filled block. It's a race engine and a stiff solid block is always a good thing.

I've heard the argument that filling a block just makes it heavier. While that is true for the engine on the stand, it doesn't hold up as well when you figure out how much water your not going to have in the system due to the fill. So in all reality you only gain a few pounds with a filled block.

Last edited by Smitty275; February 23rd, 2014 at 03:09 AM.

#6

I have 4-bolt main caps from Program Engineering, the correct clearances, the right volume of oil in my DX. Also have a Bryant crank. I have zero worries about my bottom end. I should add that my rotating assembly is light also.

#7

It obviously depends on hp level, rotating mass, and whether it's a big block, small block or DX.

Small block, all got new ARP bolts but all were sub 400hp.

I've done a couple of DX's, sub 500hp, did nothing but studs on those.

A bunch of 475-500hp big blocks, all had at least studs, most had straps as well.

I'm currently doing a 525+big block so I did a J&S 5 main halo. Above that I'd do a full girdle no doubt.

My concern with the big blocks is the lack of meat width in the mains. You can strap them etc but that won't keep them from leaning front to back in higher rpm/hp applications.

But for all applications, I think it's irresponsible to not at least replace the bolts with new ones.

Small block, all got new ARP bolts but all were sub 400hp.

I've done a couple of DX's, sub 500hp, did nothing but studs on those.

A bunch of 475-500hp big blocks, all had at least studs, most had straps as well.

I'm currently doing a 525+big block so I did a J&S 5 main halo. Above that I'd do a full girdle no doubt.

My concern with the big blocks is the lack of meat width in the mains. You can strap them etc but that won't keep them from leaning front to back in higher rpm/hp applications.

But for all applications, I think it's irresponsible to not at least replace the bolts with new ones.

#8

Thanks for taking the time to post all that Smitty. I'm glad we have this forum to discuss performance options and not have it turn into a **** storm 100% of the time. Is your bed plate made from aluminum or steel. I went to Rocket Racing a few years back and had a conversation with John about his girdle and aluminum main caps. I asked about the strength of the welds versus a one piece girdle. His opinion was, when built properly, with good weld penetration, it would be just as strong as the one piece unit. He said if you have a lower end failure that pulls apart the welds on his girdle, you have a much bigger problem. I also asked about the use of aluminum main caps. He explained that they help to reduce harmonics and absorb some of the damaging lower end vibration. It seems like Classic Oldsmobile has a lot of cruisers as members, and not as many racers, but hopefully we can change that.

Last edited by 67 Cutlass Freak; February 23rd, 2014 at 07:38 AM.

#9

The aluminum main caps are OK. Nothing wrong with them at all. I have made aluminum caps for DX builds. When you think about, just what does an aluminum block use for main caps. Sure isn't iron. LOL. And John is right, with proper weld penetration its just as strong as one solid piece and if you tear that apart your problems were far bigger than just a bottom end failure. My bedplate is also interlocked, caps into side rails, and then welded. Makes for perfect positioning every time.

I did the bedplate because I see a lot of highly stressed equipment come through where I work full time. We build new, and rebuild worn out, steel mill rolling equipment. Anytime there is a joint held together with a bolt and vibration present there is movement between the two. So with one solid piece spanning rail to rail movement potential is reduced to one large joint contained within the original cap registers and clamped with 6 studs and 10 cap screws. And as solid as it is its not going to twist enough to let clearances be effected.

At this time I have only made the bedplates out of steel. I'll gladly make one of aluminum if someone wants one. It will be just as effective, though probably cost a little more.

I did the bedplate because I see a lot of highly stressed equipment come through where I work full time. We build new, and rebuild worn out, steel mill rolling equipment. Anytime there is a joint held together with a bolt and vibration present there is movement between the two. So with one solid piece spanning rail to rail movement potential is reduced to one large joint contained within the original cap registers and clamped with 6 studs and 10 cap screws. And as solid as it is its not going to twist enough to let clearances be effected.

At this time I have only made the bedplates out of steel. I'll gladly make one of aluminum if someone wants one. It will be just as effective, though probably cost a little more.

Last edited by Smitty275; February 23rd, 2014 at 07:20 AM.

#10

Copy cat Halo

I forgot to mention the piece of junk Halo that is offered on Ebay. This turd is hardly worth mentioning but I wanted to warn everyone to avoid this thing and save yourself a lot of headaches-

http://www.ebay.com/itm/OLDSMOBILE-M...c14e86&vxp=mtr

Our very own Octania purchased one and liked it so much he decided to manufacture and market one himself-

http://www.ebay.com/itm/Oldsmobile-M...a1d192&vxp=mtr

http://www.ebay.com/itm/OLDSMOBILE-M...c14e86&vxp=mtr

Our very own Octania purchased one and liked it so much he decided to manufacture and market one himself-

http://www.ebay.com/itm/Oldsmobile-M...a1d192&vxp=mtr

#11

My opinion, like it or not......

If you want more than 800 horse, get out of Oldsmobile.

These band aids/block jock straps will hold it together, but that still doesn't make it a swell idea.

Even if you CNC your own heads to flow 400cfm at .500, the block is still junk.

Olds engines are the best torque monsters out there for the street, and that's where I'd keep them. All the extreme go fast guys are at least 51% insane.

I do appreciate insanity, but 49% in the logic category is a pretty low score.

If you want more than 800 horse, get out of Oldsmobile.

These band aids/block jock straps will hold it together, but that still doesn't make it a swell idea.

Even if you CNC your own heads to flow 400cfm at .500, the block is still junk.

Olds engines are the best torque monsters out there for the street, and that's where I'd keep them. All the extreme go fast guys are at least 51% insane.

I do appreciate insanity, but 49% in the logic category is a pretty low score.

#12

My opinion, like it or not......

If you want more than 800 horse, get out of Oldsmobile. Unless you do a DX, imo.

These band aids/block jock straps will hold it together, but that still doesn't make it a swell idea. X2

Even if you CNC your own heads to flow 400cfm at .500, the block is still junk. X2

Olds engines are the best torque monsters out there for the street, and not made to turn high rpm's (big blocks)

If you want more than 800 horse, get out of Oldsmobile. Unless you do a DX, imo.

These band aids/block jock straps will hold it together, but that still doesn't make it a swell idea. X2

Even if you CNC your own heads to flow 400cfm at .500, the block is still junk. X2

Olds engines are the best torque monsters out there for the street, and not made to turn high rpm's (big blocks)

Jmo.

#13

AL is about 1/3 as rigid as steel/ iron, therefore, generally it needs to be thicker to do the same job, deflection-wise.

I'd be worried about inter-cylinder breathing on an AL deep fat main cap/ girdle fixture if it weren't for those openings in the main webs. But I admit I have no experience with very high output engines. I did read an article on the Northstar V8 once wherein they claimed they got ~50 free HP by making holes in the main webs to allow intercylinder breathing.

"I forgot to mention the piece of junk Halo that is offered on Ebay. This turd is hardly worth mentioning but I wanted to warn everyone to avoid this thing and save yourself a lot of headaches"

==================

AGREED

I looked for discussion before shelling out my $100 or so for that pathetic pc of crap. None found. "Hot Rod Biker" still offering them?

The stud shown broke before coming to 80 ft lbs

There is NO provision to remove the studs other than double-nutting.

The stud threads galled and seized to the nuts, before I even got to the 3rd mockup install- the final assembly for the line hone that everyone recommends.

No instructions or torque recommendations.

No provision for the dipstick tube. If you cut away enough material to fit the tube, you no longer have a connection there.

Soft poor quality steel- every part of it. Nuts were digging into the halo steel even before attempting to torque them down fully- just the test mockup for oil pan fitment, etc.

Extends too far forward, offering NO additional strength, just extra weight, and that part hits the pan.

Most incredible failfest I have seen in a long time. Thus the humorous warning/ ad.

I'd be worried about inter-cylinder breathing on an AL deep fat main cap/ girdle fixture if it weren't for those openings in the main webs. But I admit I have no experience with very high output engines. I did read an article on the Northstar V8 once wherein they claimed they got ~50 free HP by making holes in the main webs to allow intercylinder breathing.

"I forgot to mention the piece of junk Halo that is offered on Ebay. This turd is hardly worth mentioning but I wanted to warn everyone to avoid this thing and save yourself a lot of headaches"

==================

AGREED

I looked for discussion before shelling out my $100 or so for that pathetic pc of crap. None found. "Hot Rod Biker" still offering them?

The stud shown broke before coming to 80 ft lbs

There is NO provision to remove the studs other than double-nutting.

The stud threads galled and seized to the nuts, before I even got to the 3rd mockup install- the final assembly for the line hone that everyone recommends.

No instructions or torque recommendations.

No provision for the dipstick tube. If you cut away enough material to fit the tube, you no longer have a connection there.

Soft poor quality steel- every part of it. Nuts were digging into the halo steel even before attempting to torque them down fully- just the test mockup for oil pan fitment, etc.

Extends too far forward, offering NO additional strength, just extra weight, and that part hits the pan.

Most incredible failfest I have seen in a long time. Thus the humorous warning/ ad.

Last edited by Octania; February 23rd, 2014 at 11:43 AM.

#14

I plan on the 4 main no machine girdle for my 403 for 3 reasons, cost, rpm and weight of parts. I have 550 gram pistons on sbc Scat rods, plan on 5500 rpm max and want this done before I am old and gray .

.

.

.

Last edited by olds 307 and 403; February 23rd, 2014 at 01:43 PM.

#15

What about for a small block besides the 403 and their dreaded windowed mains .I have a block with studs and straps that was aling honed I got for free. At what point does a small block need it if at all I was thinking about using it for my current build but I think I will bearly clip over 400 hp. Is it cheap insurance ? Or just a waste.

Last edited by coppercutlass; February 23rd, 2014 at 01:29 PM.

#17

I'm still on the fence. My current build I planned to use the block I got which is already bored out and zero decked. The block I got with the studs and straps needs to be cleaned , magged , bored out and decked. But as of now I'm holding off and finishing it as my window of opportunity has closed so I may opt to do the block work on the strap fitted block but I'm. Still on the fence.

#18

At 400hp your fine just the way it sits. On a non-windowed SBO you can make a lot more power before needing extra support. Over 500-550 I would want to at least move to better caps. At what point you'd need to go to a girdle I really don't know. Most people going to that level of power go straight to a D/DX block.

#19

Suggestion

You say this is a "no machine" girdle. Could you please explain. If each of the caps is not the exact same height off the crank, how could it possibly distribute equal clamping forces on each cap? I would still recommend a line hone on the caps after installation. Whatever halo or girdle is used, it always changes the clamping force on the caps. This can change the concentricity, or perfect roundness of the bore. By the way olds 307 and 403, could you please share with us the cost of your complete bottom end, parts and labor? If you don't want to, I understand.

#20

I'm still on the fence. My current build I planned to use the block I got which is already bored out and zero decked. The block I got with the studs and straps needs to be cleaned , magged , bored out and decked. But as of now I'm holding off and finishing it as my window of opportunity has closed so I may opt to do the block work on the strap fitted block but I'm. Still on the fence.

Copper, just take the studs and straps out of the other block and use them in your latest build with the new pistons and decked block. It's not like the studs and straps are married to that block for life. Just be sure to line hone after installation.

#22

I agree with Mark and J on this completely! When I worked at the race engine shop, we had several clients who insisted on dumping $ into stock blocks. None were Olds, BBFs, BBMs. Most ended poorly. One BBF in particular stands out. The guy had $15,000 in it and it failed. It really illistrates the importance of planning out a build and not constantly changing plans.

#23

I agree with Mark and J on this completely! When I worked at the race engine shop, we had several clients who insisted on dumping $ into stock blocks. None were Olds, BBFs, BBMs. Most ended poorly. One BBF in particular stands out. The guy had $15,000 in it and it failed. It really illistrates the importance of planning out a build and not constantly changing plans.

Mark, and Jim, you may or may not realize this, but anybody that chooses to run an Oldsmobile, is a little goofy in the head. It's always going to be less expensive to build a Chevy. I have become Oldsmobile brand loyal for my race car because I like to be different. I am one of the few who will go down that road that is less travelled. As long as I own my car it will always have an Olds power plant. I realize there's limitations with our blocks. The diesel and Nascar blocks can handle a lot of HP. My car is set up for a BB. I have two extra blocks. We need to do what we can to make our Olds live. This is why we have used girdles, halos, and now cages. We're just tryin' to keep our **** together. I wish someone had a chart, with clinical testing, that would show what level each support system is capable of handling. You're right the amount of money we spend to keep our blocks from taking a dump is a little crazy.

#24

Mark, and Jim, you may or may not realize this, but anybody that chooses to run an Oldsmobile, is a little goofy in the head. It's always going to be less expensive to build a Chevy. I have become Oldsmobile brand loyal for my race car because I like to be different. I am one of the few who will go down that road that is less travelled. As long as I own my car it will always have an Olds power plant. I realize there's limitations with our blocks. The diesel and Nascar blocks can handle a lot of HP. My car is set up for a BB. I have two extra blocks. We need to do what we can to make our Olds live. This is why we have used girdles, halos, and now cages. We're just tryin' to keep our **** together. I wish someone had a chart, with clinical testing, that would show what level each support system is capable of handling. You're right the amount of money we spend to keep our blocks from taking a dump is a little crazy.

#25

I don't see where the disappointment and frustration is. Before the internet there were lots of people trying different things and having troubles. Now that information has been shared that's not so much the case. If the build is planned out with quality parts and machine work there is no disappointment, no frustration, just lots of fun once it's done. It goes together makes great power and lives. The expense is expected. To build a BBC with the same quality of parts is not cheap either, it's a very minor cost difference. The only way it's significantly cheaper is if it's filled with Chineseium. And this is not meant to put anyone down but the simple fact is that if a person can't afford to build and maintain an Olds he can't afford a BBC of like quality either. I will concede that once you start pushing that 900HP range the Chevy is the better option. But your looking at aftermarket blocks and high quality parts also.

The majority of engine failures I see are directly attributable to the owner and this goes for all makes. They won't run a good oil filter. Put the cheapest thing on they can find and then wonder why the bearings failed because they couldn't get enough oil. And not to forget the guy who flat out forgot to put the oil filter on. To much timing. Screwed up carb with a lean spot through the transition, and many other things. If I didn't think the 4 bolt conversion and bedplate didn't work properly and provide adequate insurance against failure I wouldn't use them. Who else out there guarantees every engine out of their shop, including the race engines that come off the dyno at over 800hp.

And to comment on 67CF's post....Yes, my wife tells me often that I am just not right in the head. So I think maybe your on to something there.

The majority of engine failures I see are directly attributable to the owner and this goes for all makes. They won't run a good oil filter. Put the cheapest thing on they can find and then wonder why the bearings failed because they couldn't get enough oil. And not to forget the guy who flat out forgot to put the oil filter on. To much timing. Screwed up carb with a lean spot through the transition, and many other things. If I didn't think the 4 bolt conversion and bedplate didn't work properly and provide adequate insurance against failure I wouldn't use them. Who else out there guarantees every engine out of their shop, including the race engines that come off the dyno at over 800hp.

And to comment on 67CF's post....Yes, my wife tells me often that I am just not right in the head. So I think maybe your on to something there.

#26

You know a LOT more than I do and have MUCH more experience, but I respectfully disagree. The point where the "split" between 45 year old iron and new aftermarket blocks is quite a bit lower than 900 HP. IMHO.

#27

We still have diesel and NASCAR blocks, which should be good for a lot of power. Unfortunately BBO are expensive to buy up here and no doubt getting hard to find everywhere. I can still find good 68-76 350's for $100-$200, 403's harder to find and about the same $500-$700 range as the 455.

Last edited by olds 307 and 403; February 23rd, 2014 at 04:09 PM.

#28

First off I will start by saying that I am not right in the head. Now that that is out of the way I am one of those currently dumping a pile of money into building a big block. I know that I could build a BBC for less and only need to pick up a Summit catalog but then I would be just like everyone else and what fun would that be? I like when people walk up to you and see that you are running an Olds and look suprised and start asking questions. I am using Smitty's 4 bolt main conversion and a light reciprocating assembly. Shooting for 730-750HP.

#29

I like this

chadman, can you give us any more details about your rotating assembly? Like what pistons, crank, and comression ratio? I can understand if you don't want to post up cost, after all your wife might be following along. It sure would be cool if you could get Smitty to post up some photos of the install procedure on the caps. Thanks for sharing.

#31

It will be as follows:

Wiseco 4.250 bore flat top pistons w/ .990 pins

GRP aluminum rods

425 crank offset to 4.35 w/ 2.100 SBC journal

ATI damper

Internally balanced

494 CID 13:1 compression (chosen to run on readily available fuel)

Wiseco 4.250 bore flat top pistons w/ .990 pins

GRP aluminum rods

425 crank offset to 4.35 w/ 2.100 SBC journal

ATI damper

Internally balanced

494 CID 13:1 compression (chosen to run on readily available fuel)

#32

People here can usually agree to disagree here, not necessary this time . We are all nuts to run the Olds V8. I love to be different and our Olds V8 cars growing up were crazy reliable and took tons of abuse. That should be an awesome build Chadman has Smitty putting together . Great thread showing all the girdle's for our Olds V8.

. We are all nuts to run the Olds V8. I love to be different and our Olds V8 cars growing up were crazy reliable and took tons of abuse. That should be an awesome build Chadman has Smitty putting together . Great thread showing all the girdle's for our Olds V8.

. We are all nuts to run the Olds V8. I love to be different and our Olds V8 cars growing up were crazy reliable and took tons of abuse. That should be an awesome build Chadman has Smitty putting together . Great thread showing all the girdle's for our Olds V8.

. We are all nuts to run the Olds V8. I love to be different and our Olds V8 cars growing up were crazy reliable and took tons of abuse. That should be an awesome build Chadman has Smitty putting together . Great thread showing all the girdle's for our Olds V8.

#33

#34

I see on ROP there is a statement that straps are better than the Halo, thoughts? For my build I picked up some used Venolia 2618 custom forged 550 gram pistons with a thin ring pack with a .927 pin on Scat 6" long, 2" journal rods. I also purchased a 330 crank stroked to 3.5" from Smitty, will equal 425 ci. I am planning on a line hone with the Halo installed.

#35

I think the straps are a joke.... Studs yes...

The Halo??? Well if it fit real tight it might help with cap walk but it seems like a waste of time to me too...

Billet caps seem to me to be the way to go along with light weight assembly and keep the RPMs down under 6000...

Need a billet crank, LIGHT pistons and rods, a real girdle and a filled block and a perfect tune up to keep a BBO together.... Oiling system mods need to be done...

Then theres the heads, valve train, spin it to 7700 rpm and hope it all holds together .... Got $$$???

.... Got $$$???

The Halo??? Well if it fit real tight it might help with cap walk but it seems like a waste of time to me too...

Billet caps seem to me to be the way to go along with light weight assembly and keep the RPMs down under 6000...

Need a billet crank, LIGHT pistons and rods, a real girdle and a filled block and a perfect tune up to keep a BBO together.... Oiling system mods need to be done...

Then theres the heads, valve train, spin it to 7700 rpm and hope it all holds together

.... Got $$$???

.... Got $$$???

#36

Take a stock main cap and put it in a hydraulic press with a pressure gage. See how much pressure it takes to deform it. It won't take much and it will just snap. Now take a tool steel strap and do the same. You will find that it will take much more pressure and then it will bend as opposed to snapping in half. Now how can something that is stronger than the entire cap itself added on in addition to the cap not be beneficial?

I will agree that I think a billet cap is far better but they are in a totally different price point. Then the weakest link is the main webbing and the failure point is where the studs attach to the block.

I will agree that I think a billet cap is far better but they are in a totally different price point. Then the weakest link is the main webbing and the failure point is where the studs attach to the block.

#37

That may be but the block is no stronger than the cap right????

Some very fast Olds run aluminum caps...

If your breaking the stock cap Id the think the block will be toast too...

Some very fast Olds run aluminum caps...

If your breaking the stock cap Id the think the block will be toast too...

#38

And I don't see how straps are equal to or better than a halo. Straps do nothing for vertical support of the main caps and webbing.

I did a 2 bolt BBC last spring that made 520/540 with no concern of the main webbing or caps. Do that in an Olds and most agree a halo and studs is the minimum you should do.

The reality is all this is just a band aid.

Last edited by cutlassefi; February 27th, 2014 at 09:52 AM.

#39

I am at each end of the spectrum. The 507 has stock caps with studs and straps. The engine was torn down & checked after the first two seasons,and the bearings were perfect,so it has been left alone since,and that was 1998 or 1999. It has an N-crank,Eagle rods,and Ross pistons.Nothing fancy,but effective,and the block is filled to the water pump holes.It also doesn't get spun past 5800.

The 517 is at the other end. It has Noel's full girdle,which is definitely the best block support out there.This block does not have filler,and the rotating assembly consists of a Velasco 4.700" billet crank,GRP rods,and CP pistons.A considerably lighter rotating assembly combined with superior block support is capable of handling the big power.

I know there was some talk about possible issues with the oil pan hitting the crossmember,with Noel's girdle.When I did the r&d for Moroso's aluminum fabbed pans,I did some mock-up with the girdle and a stock pan,and the fit was better than expected. The belly of the pan did come in contact with the crossmember,but some light massaging of that area of the pan cured that. It did not put that area of the pan closer to the crank,compared to stock,because it was still spaced away with the girdle. The combination of the BBO frame pads and BBO mounts made the interference even less,almost none. Once the final design of the Moroso fabbed aluminum pan was made,they made mine shorter,to take account of the girdle,so it fits without modifying the crossmember.

I have an assortment of different makes of billet caps for my resto engines. I have BTR,Dick Miller,and another set that I had made. I don't think any of these has an advantage over the other,but are better than a stock cap.They just don't make the block stronger. There are still two bolts going into thin webbing.

The 517 is at the other end. It has Noel's full girdle,which is definitely the best block support out there.This block does not have filler,and the rotating assembly consists of a Velasco 4.700" billet crank,GRP rods,and CP pistons.A considerably lighter rotating assembly combined with superior block support is capable of handling the big power.

I know there was some talk about possible issues with the oil pan hitting the crossmember,with Noel's girdle.When I did the r&d for Moroso's aluminum fabbed pans,I did some mock-up with the girdle and a stock pan,and the fit was better than expected. The belly of the pan did come in contact with the crossmember,but some light massaging of that area of the pan cured that. It did not put that area of the pan closer to the crank,compared to stock,because it was still spaced away with the girdle. The combination of the BBO frame pads and BBO mounts made the interference even less,almost none. Once the final design of the Moroso fabbed aluminum pan was made,they made mine shorter,to take account of the girdle,so it fits without modifying the crossmember.

I have an assortment of different makes of billet caps for my resto engines. I have BTR,Dick Miller,and another set that I had made. I don't think any of these has an advantage over the other,but are better than a stock cap.They just don't make the block stronger. There are still two bolts going into thin webbing.

#40