They don't make them like they used to, Thank God!

#1

They don't make them like they used to, Thank God!

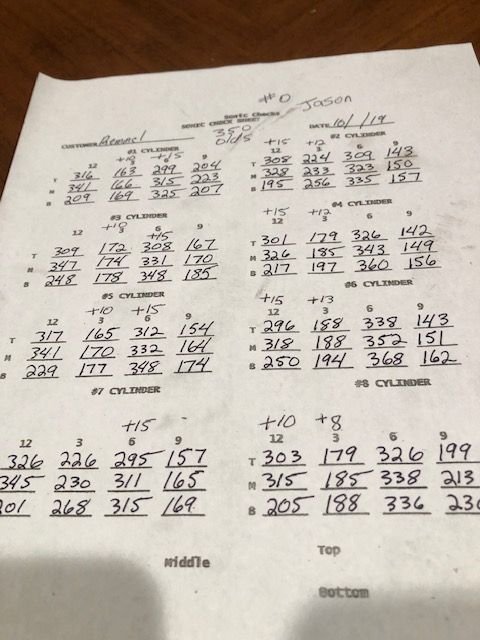

Attached you'll see what it means by "going the extra mile" in machine work. Take note of the sonic check sheet showing the amount of offset in the bores. My guy was nice enough to register the amount of offset the bores had in relation to being correct. You can see some are way of, and not just at 3 and 9 o'clock(the piston can easily just slide on the wrist pin at that point)

The next pictures are of a SBO being bored the Right way to correct the offset. The fixture being used is a BHJ BorTru. The boring bar is centered in the plate, NOT the bores. It correctly locates the bores AFTER the block has been align honed and truly square decked. . Needless to say I'm glad they don't make them like they used to, their machining was horrible!!!

We make them as good as physically possible. I believe that's one reason why my builds make as much or more power as anyone else out there. I can tell you they're not all this bad but most are close to this. We machine every block this way, unless the customer doesn't want to pay the extra $250.00. I think it's worth 5 times that. Just an fyi.

Hope this helps.

P.S. did one today that had one bank shifted over .020 towards the lifters. The other bank was about .012-.015.

Last edited by cutlassefi; October 29th, 2019 at 06:44 PM.

#2

Please do not take this the wrong way., but how does a block check out after a season of hard abuse, street/strip etc ???? The reason I ask this ., is if the stock crank even forged is as a weak as its been claimed to be then how soft is the block and how long will all that work last ??? I don't build enough engines in one year let alone enough of my own to see this kind of stuff but Im also curious as to how much the typical street strip engine moves after all this is done. I know people throw the " seasoned block " term out there but what happens after all this work sees abuse on a 50 year old engine block ? How much consistency does it keep.

#3

Machining equipment precision has gotten way better, in 50 years. Factory production machinery runs a lot more volume on rough castings than after market machinery. I am not surprised "blueprinting" old engines corrects things. Thanks for the photo's.

Last edited by OLDSter Ralph; October 30th, 2019 at 12:10 AM.

#4

Please do not take this the wrong way., but how does a block check out after a season of hard abuse, street/strip etc ???? The reason I ask this ., is if the stock crank even forged is as a weak as its been claimed to be then how soft is the block and how long will all that work last ??? I don't build enough engines in one year let alone enough of my own to see this kind of stuff but Im also curious as to how much the typical street strip engine moves after all this is done. I know people throw the " seasoned block " term out there but what happens after all this work sees abuse on a 50 year old engine block ? How much consistency does it keep.

Another thing to notice is the difference in wall thickness in the same cylinder. Except for the end cylinders, which typically have uneven wall thickness anyway, the “imbalance” pretty much makes them concentric doesn’t it. That’s why I’ve never totally subscribed to the “core shift” theory. Again this is just poor machining from the start.

In addition my crank guy checks and corrects the stroke and index of the cranks. My old dyno guy always commented on just how smooth my builds ran. These steps play a big part in that as well as a quality balance job.

Again just an FYI.

Last edited by cutlassefi; October 30th, 2019 at 04:39 AM.

#5

Interesting

So in most cases doing a rebuild on an Olds motor more than likely would require a bore and oversized pistons? Have you ever come across an Olds motor or any 50 yr old block that is within tolerances and only requires a hone?

Eventually, Ill have a 455 rebuilt but want to prepare myself for what is to come and also do it the right way.

So in most cases doing a rebuild on an Olds motor more than likely would require a bore and oversized pistons? Have you ever come across an Olds motor or any 50 yr old block that is within tolerances and only requires a hone?

Eventually, Ill have a 455 rebuilt but want to prepare myself for what is to come and also do it the right way.

#6

I bore everything but yes some are only off a few thousandths. But you don’t know that until the square decking has been done and the plate installed.

It takes approx 6 hours just to bore the block in this manner.

It takes approx 6 hours just to bore the block in this manner.

#7

Thanks Mark. I know when i worked in a machine shop where me made ring gears the hardening process would give us about .005 once we put it on the tester. We usually could hold .002 but our machines where old and i mean old. So we always had to reface the gears after heat treat to get the runout within spec. I guess this is where my core change theory application comes from. Although I know engines dont see as much extreme heat they do see some with enough torsional power to move things but again like you said seeing and believing are 2 different things. I just didnt know if that whole theory was true after making a block nice and square. Nice work.

#9

Hm that bore thru is a guide looks thin. Jmo now after block drilling bad holes with bomb sites and using steel guides lock down using reamers that can step ream. I see something that appears can have a ut oh. When I say drilling i mean I have done this daily in the aircraft industry 30+ years. All sizes different metals. Thick material and thin. To sum it up cool picture great info. Can you post a picture of cutter please. Thanks for all you do Mark.

#10

As Ralph said, this is bad machining from the start. The only thing that moves from here would be the cylinder walls if they’re too thin(below .100 seems to be the general consensus). I can tell you categorically the SBO Block is way stronger than any cast crank so it flexes way less than the crank does.

Another thing to notice is the difference in wall thickness in the same cylinder. Except for the end cylinders, which typically have uneven wall thickness anyway, the “imbalance” pretty much makes them concentric doesn’t it. That’s why I’ve never totally subscribed to the “core shift” theory. Again this is just poor machining from the start.

In addition my crank guy checks and corrects the stroke and index of the cranks. My old dyno guy always commented on just how smooth my builds ran. These steps play a big part in that as well as a quality balance job.

Again just an FYI.

Another thing to notice is the difference in wall thickness in the same cylinder. Except for the end cylinders, which typically have uneven wall thickness anyway, the “imbalance” pretty much makes them concentric doesn’t it. That’s why I’ve never totally subscribed to the “core shift” theory. Again this is just poor machining from the start.

In addition my crank guy checks and corrects the stroke and index of the cranks. My old dyno guy always commented on just how smooth my builds ran. These steps play a big part in that as well as a quality balance job.

Again just an FYI.

#12

As Ralph said, this is bad machining from the start. The only thing that moves from here would be the cylinder walls if they’re too thin(below .100 seems to be the general consensus). I can tell you categorically the SBO Block is way stronger than any cast crank so it flexes way less than the crank does.

Another thing to notice is the difference in wall thickness in the same cylinder. Except for the end cylinders, which typically have uneven wall thickness anyway, the “imbalance” pretty much makes them concentric doesn’t it. That’s why I’ve never totally subscribed to the “core shift” theory. Again this is just poor machining from the start.

In addition my crank guy checks and corrects the stroke and index of the cranks. My old dyno guy always commented on just how smooth my builds ran. These steps play a big part in that as well as a quality balance job.

Again just an FYI.

Another thing to notice is the difference in wall thickness in the same cylinder. Except for the end cylinders, which typically have uneven wall thickness anyway, the “imbalance” pretty much makes them concentric doesn’t it. That’s why I’ve never totally subscribed to the “core shift” theory. Again this is just poor machining from the start.

In addition my crank guy checks and corrects the stroke and index of the cranks. My old dyno guy always commented on just how smooth my builds ran. These steps play a big part in that as well as a quality balance job.

Again just an FYI.

Thanks Mark. I know when i worked in a machine shop where me made ring gears the hardening process would give us about .005 once we put it on the tester. We usually could hold .002 but our machines where old and i mean old. So we always had to reface the gears after heat treat to get the runout within spec. I guess this is where my core change theory application comes from. Although I know engines dont see as much extreme heat they do see some with enough torsional power to move things but again like you said seeing and believing are 2 different things. I just didnt know if that whole theory was true after making a block nice and square. Nice work.

1. There are differences between an engine block that has been mass produced with manufacturing tolerances and a "hand built" item. Engines were produced by the thousands each day. The fixtures could vary based on the wear of the locating pins, fixture condition, machinery condition and manufacturing tolerances. They shouldn't be expected to be as "perfect" as Mark makes them.

2. Think how many engines Mark could produce (4) in a 24 hour day compared to the hundreds of engines required each day to supply the Cutlass line with engines in just one plant. Add in the number of B bodies and you have a very large number.

3. Blueprinting has always "corrected" manufacturing differences. The blueprinted engine has always outperformed a "production engine". Deck height, CC's and such fall with in a range, with a blueprinted engine,everything is at favorable conditions. If people compare the price of a"crate engine" to what Mark charges, there is a difference.......because there is a difference !

4. An engine block is "poured" and subject to internal stresses since it cools at different rates. Machining releases some of those stresses and they "move around". A "seasoned block" has been subjected to heating and cooling cycles that further reduces most of those leftover internal stresses. "Sub zero tempering", submerging the engine block in liquid nitrogen could reduce more internal stresses further.

5. Distortion of ring gears bases on the steel/quench method (air, oil, water, etc.). How they are dropped in the quench oil/water can cause more or less distortion. Generally speaking......air hardening produces the least distortion, oil causes more distortion, and water causes the most. "Core shift" is something different. Core shift has more to do with alignment of the top mold to bottom mold.

If you have anything to add, jump in.

#13

Ralph- I hear what you’re saying but I can bet you a weeks pay that the new LS is not machined nearly as poorly as some of the Oldsmobile blocks I’ve run across.

#14

Although i did mention heat treat we would often have to remake gears that came in and the engineering dept would reverse engineer them. Once they got demesions we would put them on the tester. Use , heat while in use and abuse would distort the crap out of them. I just asked out of curiosity. I perhaps used the wrong example but an engine see's heat cycles and its cast so I dont think they will ever truly maintain those tolerances after a life of abuse. And thats not to dog marks work but more or less im really curious if he gets an engine back thats been heavily abuse what it specs out at.

But according to top builders the stock rods pretty much will stretch and distort pretty fast so im curious at what rate that happens on a block . considering the small block olds block is plenty stout and the rotating mass is much lighter in comparison to a BBO but in a BBO its been noted the block is a weak link. So wether you use a halo girdle , cap straps or a full girdle whats the longevity of this with all that weight being thrown around then putting a load behind it you have pistons that naturally side load so things have to move at some rate.

Not being a smartass either just curious.

It's like engine balancing. You balance the rotating assembly but everything you put on the ends of the crank significantly change things so.... Does it really stay in balance ???. Nit arguing the theory on that one. But that question is one I always wondered about much like how square a block stays

But according to top builders the stock rods pretty much will stretch and distort pretty fast so im curious at what rate that happens on a block . considering the small block olds block is plenty stout and the rotating mass is much lighter in comparison to a BBO but in a BBO its been noted the block is a weak link. So wether you use a halo girdle , cap straps or a full girdle whats the longevity of this with all that weight being thrown around then putting a load behind it you have pistons that naturally side load so things have to move at some rate.

Not being a smartass either just curious.

It's like engine balancing. You balance the rotating assembly but everything you put on the ends of the crank significantly change things so.... Does it really stay in balance ???. Nit arguing the theory on that one. But that question is one I always wondered about much like how square a block stays

Last edited by coppercutlass; October 30th, 2019 at 10:31 AM.

#15

Cylinder walls distort no doubt. But they don’t stay that way to any great degree unless there’s a significant weakness in the block/walls. Again this is an initial machining issue, not a heat cycle or permanent distortion issue.

Last edited by cutlassefi; October 30th, 2019 at 10:35 AM.

#17

Let me add some info to the discussion.

1. There are differences between an engine block that has been mass produced with manufacturing tolerances and a "hand built" item. Engines were produced by the thousands each day. The fixtures could vary based on the wear of the locating pins, fixture condition, machinery condition and manufacturing tolerances. They shouldn't be expected to be as "perfect" as Mark makes them.

2. Think how many engines Mark could produce (4) in a 24 hour day compared to the hundreds of engines required each day to supply the Cutlass line with engines in just one plant. Add in the number of B bodies and you have a very large number.

3. Blueprinting has always "corrected" manufacturing differences. The blueprinted engine has always outperformed a "production engine". Deck height, CC's and such fall with in a range, with a blueprinted engine,everything is at favorable conditions. If people compare the price of a"crate engine" to what Mark charges, there is a difference.......because there is a difference !

4. An engine block is "poured" and subject to internal stresses since it cools at different rates. Machining releases some of those stresses and they "move around". A "seasoned block" has been subjected to heating and cooling cycles that further reduces most of those leftover internal stresses. "Sub zero tempering", submerging the engine block in liquid nitrogen could reduce more internal stresses further.

5. Distortion of ring gears bases on the steel/quench method (air, oil, water, etc.). How they are dropped in the quench oil/water can cause more or less distortion. Generally speaking......air hardening produces the least distortion, oil causes more distortion, and water causes the most. "Core shift" is something different. Core shift has more to do with alignment of the top mold to bottom mold.

If you have anything to add, jump in.

1. There are differences between an engine block that has been mass produced with manufacturing tolerances and a "hand built" item. Engines were produced by the thousands each day. The fixtures could vary based on the wear of the locating pins, fixture condition, machinery condition and manufacturing tolerances. They shouldn't be expected to be as "perfect" as Mark makes them.

2. Think how many engines Mark could produce (4) in a 24 hour day compared to the hundreds of engines required each day to supply the Cutlass line with engines in just one plant. Add in the number of B bodies and you have a very large number.

3. Blueprinting has always "corrected" manufacturing differences. The blueprinted engine has always outperformed a "production engine". Deck height, CC's and such fall with in a range, with a blueprinted engine,everything is at favorable conditions. If people compare the price of a"crate engine" to what Mark charges, there is a difference.......because there is a difference !

4. An engine block is "poured" and subject to internal stresses since it cools at different rates. Machining releases some of those stresses and they "move around". A "seasoned block" has been subjected to heating and cooling cycles that further reduces most of those leftover internal stresses. "Sub zero tempering", submerging the engine block in liquid nitrogen could reduce more internal stresses further.

5. Distortion of ring gears bases on the steel/quench method (air, oil, water, etc.). How they are dropped in the quench oil/water can cause more or less distortion. Generally speaking......air hardening produces the least distortion, oil causes more distortion, and water causes the most. "Core shift" is something different. Core shift has more to do with alignment of the top mold to bottom mold.

If you have anything to add, jump in.

#18

No, only in piston and bearing clearances. I don’t believe they had the resources to properly bore these blocks back then. Think about it, if they had the ability to really control tolerances and overall machining, they wouldn’t have to mix-and-match pistons etc.

Last edited by cutlassefi; October 30th, 2019 at 11:10 AM.

#20

Nice to see you go the extra mile on these engines...

My 400 E block was way out when checked.

It had .010 deck variance across 1 surface & the other side was .005 higher.

Ended up with a .020 cut to square everything up. At least I don't have too much deck clearance now lol...

Also the center main cap was tilted by a few thousandths making the end play too tight.

You could see 1 place where the factory thrust bearing that was worn more than the rest.

Yes, machining tolerances are way tighter in production settings today than years ago.

My 400 E block was way out when checked.

It had .010 deck variance across 1 surface & the other side was .005 higher.

Ended up with a .020 cut to square everything up. At least I don't have too much deck clearance now lol...

Also the center main cap was tilted by a few thousandths making the end play too tight.

You could see 1 place where the factory thrust bearing that was worn more than the rest.

Yes, machining tolerances are way tighter in production settings today than years ago.

#21

Nothing wrong with a sleeve, if it’s installed correctly. However too many shops don’t take the trouble to do it the right way.

Ralph- I hear what you’re saying but I can bet you a weeks pay that the new LS is not machined nearly as poorly as some of the Oldsmobile blocks I’ve run across.

Ralph- I hear what you’re saying but I can bet you a weeks pay that the new LS is not machined nearly as poorly as some of the Oldsmobile blocks I’ve run across.

I thought you were showing a pic of an Oldsmobile block....... a brand thats not even being produced today. I was merely providing info on what I saw and know from another life. I have owned only two Chebbies in my life, a used 76 Monte Carlo and a 1938 Chevrolet 2 door sedan with an inline 6. The '38 was driven during my college days and.........then installed a straight axle, Olds 394 with "tri power", Isky cam, B&M stick hydro and Pontiac limited slip rear end with 4.11 gears.

I thought you were showing a pic of an Oldsmobile block....... a brand thats not even being produced today. I was merely providing info on what I saw and know from another life. I have owned only two Chebbies in my life, a used 76 Monte Carlo and a 1938 Chevrolet 2 door sedan with an inline 6. The '38 was driven during my college days and.........then installed a straight axle, Olds 394 with "tri power", Isky cam, B&M stick hydro and Pontiac limited slip rear end with 4.11 gears.Nice to see you go the extra mile on these engines... My 400 E block was way out when checked.

It had .010 deck variance across 1 surface & the other side was .005 higher. Ended up with a .020 cut to square everything up. At least I don't have too much deck clearance now lol... Also the center main cap was tilted by a few thousandths making the end play too tight.

You could see 1 place where the factory thrust bearing that was worn more than the rest.

Yes, machining tolerances are way tighter in production settings today than years ago.

It had .010 deck variance across 1 surface & the other side was .005 higher. Ended up with a .020 cut to square everything up. At least I don't have too much deck clearance now lol... Also the center main cap was tilted by a few thousandths making the end play too tight.

You could see 1 place where the factory thrust bearing that was worn more than the rest.

Yes, machining tolerances are way tighter in production settings today than years ago.

#22

Nothing wrong with a sleeve, if it’s installed correctly. However too many shops don’t take the trouble to do it the right way.

Ralph- I hear what you’re saying but I can bet you a weeks pay that the new LS is not machined nearly as poorly as some of the Oldsmobile blocks I’ve run across.

Ralph- I hear what you’re saying but I can bet you a weeks pay that the new LS is not machined nearly as poorly as some of the Oldsmobile blocks I’ve run across.

#23

Eh not agreeing with the other makes statement. I have seen Ford's last for a lot of miles. Now old school chevys ha boat anchors always seen problems with them around 50'000 miles. Anyone remember Chevy guide problems with their heads. Bug sprayers LOL.

#25

Maybe, but I’d probably sonic check a couple of holes again after a couple of cuts to see where they really are in thickness.

From what I’ve seen, about 60-70% of the 68-76 350 blocks will go to 4.155 IF BORED CORRECTLY. That’s why I had Mahle do my Stroker piston in that bore size.

From what I’ve seen, about 60-70% of the 68-76 350 blocks will go to 4.155 IF BORED CORRECTLY. That’s why I had Mahle do my Stroker piston in that bore size.

Last edited by cutlassefi; November 3rd, 2019 at 10:33 AM.

#26

Dad stopped running Ford after getting a few lemons. I saw the same things with the sbc. The Ford 351M and 400M were junk from what I saw, wore out and knocking at 100,000 Km.

#27

Cutlasefi good post. Most don't want to take the time or spend the $$ to do it right. Not to mention finding a machine shop with competent people. Everyone wants the cheap way out. you get what you pay for. Also find someone that really knows what they are doing when it comes to head work.

I can also support about the blocks being way out and what a difference it makes when everything is corrected and matched. Take the extra time to check and recheck every part then correct it if it's not right. A well built correctly machined and balanced engine will show this on the dyno when you look at your BFSC numbers. They run smoother, cooler, more power, and more efficient.

I can also support about the blocks being way out and what a difference it makes when everything is corrected and matched. Take the extra time to check and recheck every part then correct it if it's not right. A well built correctly machined and balanced engine will show this on the dyno when you look at your BFSC numbers. They run smoother, cooler, more power, and more efficient.

#29

You don’t “adjust” the bor-tru. By centering in that plate it puts the cylinders in the right place. Sometimes they’ll clean at .030 but most times we need to go to at least .040.

#30

The bore true is a template of perfect bore location?

How is the plate indexed on the block to the correct location?

#31

#33

As described the block is align honed first. Then the Blok Tru is attached which uses the main saddles and cam tunnel to find a centerline. The decks are then squared off the machine surface of the Blok Tru. Then the Bor-Tru is installed Only after making sure the dowels line up, then it’s bolted to what is now a square and parallel deck. It’s time consuming and tedious but in my opinion the only way to do it.

Last edited by cutlassefi; November 23rd, 2019 at 05:22 AM.

#34

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,722

That, and the cam tunnel.

as described the block is align honed first. Then the Blok Tru is attached which uses the main saddles and cam tunnel to find a centerline. The decks are then squared off the machine surface of the Blok Tru. Then the Bor-Tru is installed Only after making sure the dowels line up, then it’s bolted to what is now a square and parallel deck. It’s time consuming and tedious but in my opinion the only way to do it.

as described the block is align honed first. Then the Blok Tru is attached which uses the main saddles and cam tunnel to find a centerline. The decks are then squared off the machine surface of the Blok Tru. Then the Bor-Tru is installed Only after making sure the dowels line up, then it’s bolted to what is now a square and parallel deck. It’s time consuming and tedious but in my opinion the only way to do it.

#35

Just a side note on 455 blocks. I had this Olds 455 block being cleaned and the guy called me to come down and look at the block. I got there and the block was rusty like it sat outside but guess what that's what they did back in the day to treat them. I was told yrs. ago.

I'm glad I never checked my blocks as I might not have used them but they all worked out OK.

Gerald

I'm glad I never checked my blocks as I might not have used them but they all worked out OK.

Gerald

#36

Any idea what the steel bushings are for in the BHJ Bor-Tru plate? And how do you think these plates and fixtures are machined in the first place?

Lifters bores are done with a BHJ Lifter-Tru. I have one of only two in the country for a 39* Olds. Milan has the other one I believe.

Last edited by cutlassefi; November 23rd, 2019 at 05:26 AM.

#37

#38

Just a side note on 455 blocks. I had this Olds 455 block being cleaned and the guy called me to come down and look at the block. I got there and the block was rusty like it sat outside but guess what that's what they did back in the day to treat them. I was told yrs. ago.

I'm glad I never checked my blocks as I might not have used them but they all worked out OK.

Gerald

I'm glad I never checked my blocks as I might not have used them but they all worked out OK.

Gerald

Gerald this is not meant for the average build as most don't want to spend the money.

This is for those that want the best possible starting point for a performance type build.

#39

Last edited by cutlassefi; November 22nd, 2019 at 12:37 PM.