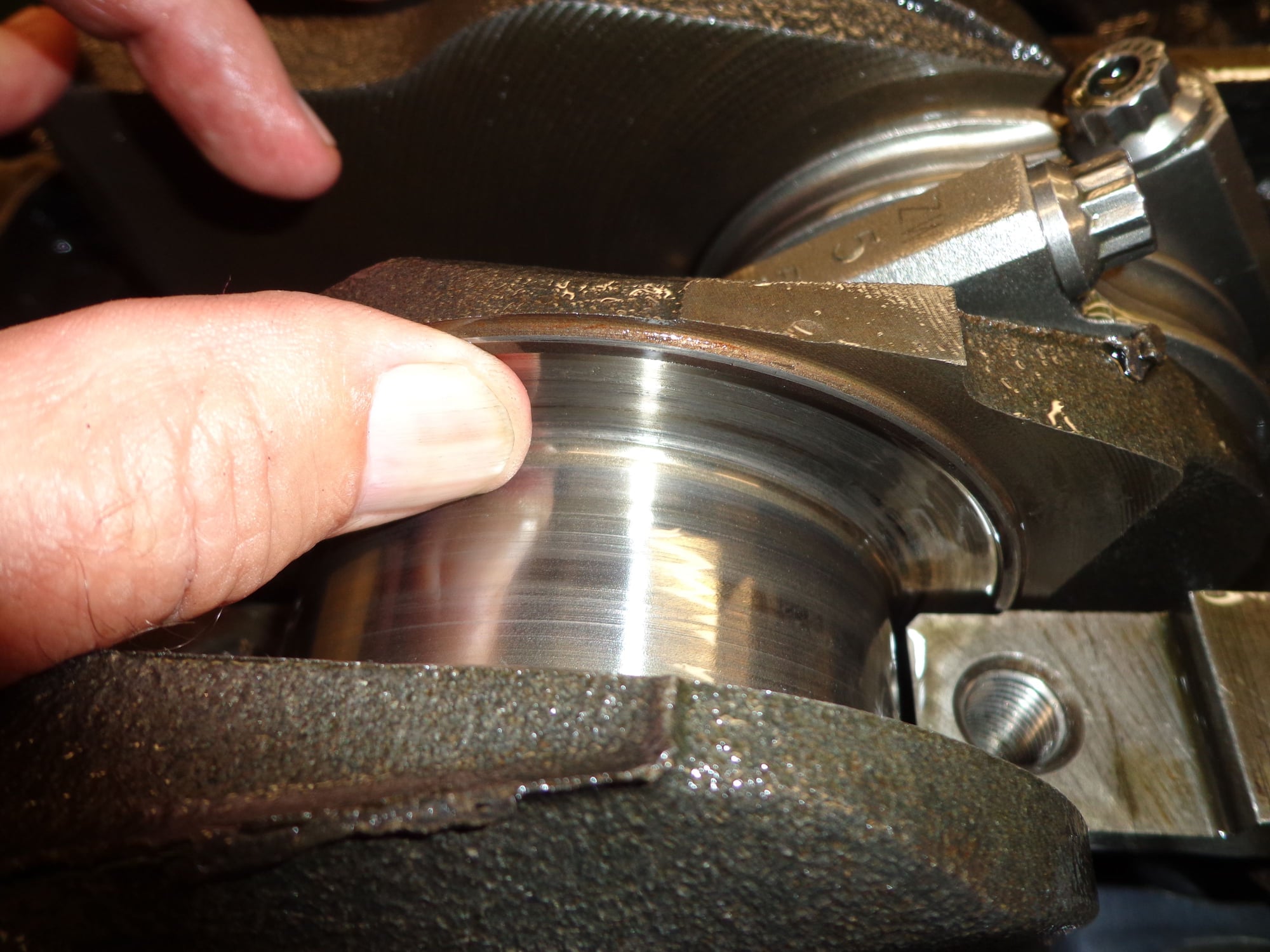

thrust bearing and crank destroyed

#1

I think I may have a unique problem. I rebuilt my 461 last winter,( again). I race it all summer so I try to freshen it every 800 runs or every 2 years . I've had a transbrake on my TH400 for 3 years but I never really used it until this year. Last Sunday the car acted funny,(unusual times and noises), so I packed up and went home. I cut the filter when I got home and it was full of copper and iron dust.I pulled the engine and the thrust bearing was almost gone on the rear side.The crank side journal was eaten into so far that the crank will now move forward almost .075 in. I called my trans guy and he said it could be the torque converter pushing on the rear of the crank! I had used the transbrake for 98 races and I have the 2 step set @ 2400 rpm, nothing excessive. My torque converter is a cone 3800 which has been gone thru twice in the last 6 years by Ultimate and the trans was completely redone 2 years ago. I've used the transbrake occasionally before but none of my old bearings showed any sign of wear. Any guesses? Oh yes one month ago I had to change my flexplate because it started rubbing on the starter and the teeth got ate up. It never dawned on me then the crank had moved forward!

#5

I took 455 Olds apart that looked exactly like yours. It had also been raced. I happen to ask a converter guy about the "BALLONING" theory. He said a converter would split or crack if it ballooned enough to push the crank forward. I'm not stating fact, just passing on what he said.

#6

Look at the pilot of the converter, and the bore of the crank. See in there is any sign of metal to metal contact. The pilot shouldnít bottom out on the crank. Call Coan, ask for what the height of the converter hub to converter pilot. Lay a straightedge across the hub, measure down to the surface the converter is sitting on.

Is the converter built for a transbrake? A transbrake compatible converter needs ballon plates.

Is the converter built for a transbrake? A transbrake compatible converter needs ballon plates.

#7

My 403 block had something bad happen to it in its past. Don't know what, but the #3 cap doesn't fit worth ****. I have to very very carefully install, torque, check, knock it around, check some more, etc etc, to get it to sit square.

So make sure when installed that you have even clearance all around the thrust. A titled cap will cause hilarious problems.

So make sure when installed that you have even clearance all around the thrust. A titled cap will cause hilarious problems.

#8

My 403 block had something bad happen to it in its past. Don't know what, but the #3 cap doesn't fit worth ****. I have to very very carefully install, torque, check, knock it around, check some more, etc etc, to get it to sit square.

So make sure when installed that you have even clearance all around the thrust. A titled cap will cause hilarious problems.

So make sure when installed that you have even clearance all around the thrust. A titled cap will cause hilarious problems.

#9

Look at the pilot of the converter, and the bore of the crank. See in there is any sign of metal to metal contact. The pilot shouldnít bottom out on the crank. Call Coan, ask for what the height of the converter hub to converter pilot. Lay a straightedge across the hub, measure down to the surface the converter is sitting on.

Is the converter built for a transbrake? A transbrake compatible converter needs balloon plates.

Is the converter built for a transbrake? A transbrake compatible converter needs balloon plates.

Thank you very much for your advice, It looks like ballooning will turn out to be the problem at this point!. Charlie

#10

Look at the pilot of the converter, and the bore of the crank. See in there is any sign of metal to metal contact. The pilot shouldnít bottom out on the crank. Call Coan, ask for what the height of the converter hub to converter pilot. Lay a straightedge across the hub, measure down to the surface the converter is sitting on.

Is the converter built for a transbrake? A transbrake compatible converter needs ballon plates.

Is the converter built for a transbrake? A transbrake compatible converter needs ballon plates.

#11

I believe it is a ballooned converter. I ruined 3 engines with one bad converter, ..

#1, The original engine in a 1993 Chevy 1/2 ton. 4X4, extended cab long bed. I used it to tow a lot, all over the country. One summer I was without a trailer and borrowed my buddies 28' enclosed, extra height and all the goodies, cabinets, winch, lights etc, ie heavy. Later that year, later that year, not towing just going to my house in town, I heard nor saw any warning signs, but started across an intersection in my small town and very near my house in a residential area, engine started making a heck of a racket, knocking horribly. I just coasted to a stop and called a friend mechanic/ machinist at the local machine shop. They build all kinds of engines, diesel, race, and whatever. He came listened said broken crank. So I told him to get a spare 350 I had at home with a blown head gasket, which I had switched out a few years back in a 1996 Chevy truck which I bought and then sold for fun and profit, and rebuild it real quick and swap them. He checked everything, including the converter while swapping them, deemed it all ok and just chalked it up to bad luck.

So now have engine #2 in truck, all is lovely until it started knocking and leaking oil in the front and rear seals.

Swapped it for an already built, new, 383 stroker short block with all new rotating assembly, and my stock heads.

Engine #3, the stroker engine with all new parts, crank, rods, pins, roller cam, built by another local racer/ engine builder for use in his truck but sold it to me instead. Ran good, not a powerhouse I thought I might have but nice. Same story, started making noise and leaking at the mains. Then I finally saw the writing on the wall, it had to be the converter.

I had engine #2 rebuilt again and pulled the 383. The same thing you are looking at in your engine was just how my 383 looked. Worn out rear thrust bearing and the thrust ring on the new crank badly worn. Nothing to do but put more money it and sell it, which I did eventually.

But I then put an expensive anti-ballooning converter and engine #2 which we fixed/rebuilt again back in the truck and drove it for a few more years and finally sold it. And bought a 2500, 2006 Chevy 4x4 extended cab truck and drove it for several years.

The #2 engine was great in the 1993 1/2 ton and no more problems after replacing the converter.

I really believe you have a bad converter based on my/ this particular series of unfortunate events.

Good luck,

Mike

#1, The original engine in a 1993 Chevy 1/2 ton. 4X4, extended cab long bed. I used it to tow a lot, all over the country. One summer I was without a trailer and borrowed my buddies 28' enclosed, extra height and all the goodies, cabinets, winch, lights etc, ie heavy. Later that year, later that year, not towing just going to my house in town, I heard nor saw any warning signs, but started across an intersection in my small town and very near my house in a residential area, engine started making a heck of a racket, knocking horribly. I just coasted to a stop and called a friend mechanic/ machinist at the local machine shop. They build all kinds of engines, diesel, race, and whatever. He came listened said broken crank. So I told him to get a spare 350 I had at home with a blown head gasket, which I had switched out a few years back in a 1996 Chevy truck which I bought and then sold for fun and profit, and rebuild it real quick and swap them. He checked everything, including the converter while swapping them, deemed it all ok and just chalked it up to bad luck.

So now have engine #2 in truck, all is lovely until it started knocking and leaking oil in the front and rear seals.

Swapped it for an already built, new, 383 stroker short block with all new rotating assembly, and my stock heads.

Engine #3, the stroker engine with all new parts, crank, rods, pins, roller cam, built by another local racer/ engine builder for use in his truck but sold it to me instead. Ran good, not a powerhouse I thought I might have but nice. Same story, started making noise and leaking at the mains. Then I finally saw the writing on the wall, it had to be the converter.

I had engine #2 rebuilt again and pulled the 383. The same thing you are looking at in your engine was just how my 383 looked. Worn out rear thrust bearing and the thrust ring on the new crank badly worn. Nothing to do but put more money it and sell it, which I did eventually.

But I then put an expensive anti-ballooning converter and engine #2 which we fixed/rebuilt again back in the truck and drove it for a few more years and finally sold it. And bought a 2500, 2006 Chevy 4x4 extended cab truck and drove it for several years.

The #2 engine was great in the 1993 1/2 ton and no more problems after replacing the converter.

I really believe you have a bad converter based on my/ this particular series of unfortunate events.

Good luck,

Mike

#13

There is a common modification that can be done to the pump to limit the pressure in the converter. Some people swear by it. I have done it a couple times. I understand the theory, it seems to me if it was really needed or a problem Hydromatic wouldnít have made the hole so big to begin with.

Something push forward on the crank with enough force to wipe out the thrust bearing. Using a transbrake with a converter thatís not built for a brake is a definite possibility.

Coan, ATI, Precision, all make top quality stuff. Quality parts arenít cheap.

Something push forward on the crank with enough force to wipe out the thrust bearing. Using a transbrake with a converter thatís not built for a brake is a definite possibility.

Coan, ATI, Precision, all make top quality stuff. Quality parts arenít cheap.

#14

A quality converter for a TH400 shouldn't be that much. Ultimate makes really good stuff (I run one of his in my TH350) but I have noticed he's pushing customers to buy the more expensive units now.

PATC also has pretty good stuff and really affordable. I think they're kind of between Hughes and the specialists, quality-wise.

PATC also has pretty good stuff and really affordable. I think they're kind of between Hughes and the specialists, quality-wise.

#15

There is a common modification that can be done to the pump to limit the pressure in the converter. Some people swear by it. I have done it a couple times. I understand the theory, it seems to me if it was really needed or a problem Hydromatic wouldnít have made the hole so big to begin with.

https://youtu.be/0bzPt-eWO0Q

Something push forward on the crank with enough force to wipe out the thrust bearing. Using a transbrake with a converter thatís not built for a brake is a definite possibility.

Coan, ATI, Precision, all make top quality stuff. Quality parts arenít cheap.

https://youtu.be/0bzPt-eWO0Q

Something push forward on the crank with enough force to wipe out the thrust bearing. Using a transbrake with a converter thatís not built for a brake is a definite possibility.

Coan, ATI, Precision, all make top quality stuff. Quality parts arenít cheap.

#16

Itís entirely too easy to make horsepower now. I build a lot of transmissions for turbo cars. Iím starting to add parts now that a few years ago would have been luxuries. The powdered iron forward clutch hub of a TH400 is pretty reliable until around 1000hp. I add a steel hub to just about everything now. I canít tell you the number of times I have built a transmission thinking the customer is making 800-900hp, then some wastegate or turbo changes and now the engine is making 1200-1300 or more. Iím guessing converter builders are doing the same.

A reworked stock cast aluminum stator use to be standard In all but the really exotic converters 10 years ago. Now itís common for junkyard LS engines with a eBay turbo to make enough power to shatter the cast stators. Iím guessing most converter builders are using custom made steel stators. Itís far cheaper to include the few extra hundred bucks for the upgraded parts, than to repair the damage when the cheaper stuff breaks.

When it comes to the drivetrain, it always seems like the budget ends at the flywheel.

A reworked stock cast aluminum stator use to be standard In all but the really exotic converters 10 years ago. Now itís common for junkyard LS engines with a eBay turbo to make enough power to shatter the cast stators. Iím guessing most converter builders are using custom made steel stators. Itís far cheaper to include the few extra hundred bucks for the upgraded parts, than to repair the damage when the cheaper stuff breaks.

When it comes to the drivetrain, it always seems like the budget ends at the flywheel.

#17

Itís entirely too easy to make horsepower now. I build a lot of transmissions for turbo cars. Iím starting to add parts now that a few years ago would have been luxuries. The powdered iron forward clutch hub of a TH400 is pretty reliable until around 1000hp. I add a steel hub to just about everything now. I canít tell you the number of times I have built a transmission thinking the customer is making 800-900hp, then some wastegate or turbo changes and now the engine is making 1200-1300 or more. Iím guessing converter builders are doing the same.

A reworked stock cast aluminum stator use to be standard In all but the really exotic converters 10 years ago. Now itís common for junkyard LS engines with a eBay turbo to make enough power to shatter the cast stators. Iím guessing most converter builders are using custom made steel stators. Itís far cheaper to include the few extra hundred bucks for the upgraded parts, than to repair the damage when the cheaper stuff breaks.

When it comes to the drivetrain, it always seems like the budget ends at the flywheel.

A reworked stock cast aluminum stator use to be standard In all but the really exotic converters 10 years ago. Now itís common for junkyard LS engines with a eBay turbo to make enough power to shatter the cast stators. Iím guessing most converter builders are using custom made steel stators. Itís far cheaper to include the few extra hundred bucks for the upgraded parts, than to repair the damage when the cheaper stuff breaks.

When it comes to the drivetrain, it always seems like the budget ends at the flywheel.

#18

This converter has balloon plates. See the solid plate welded to the neck, and covers the dip in the cover?

This converter has no ballon plates. Notice the dip under the hub.

The ballon plate basically prevents the converter from stretching and trying to force the engine and transmission apart. Some manufacturers build the rear covers from a chunk of steel, or on small diameter converter they will use fabricated mounts welded to the rear cover, anything to stiffen the body.

If your engine makes 550 hp, and you set the transbrake and stand on the throttle, that 550 hp is still there. Instead of moving the car, the power is being converted into heat. When I worked at Coan 25 years ago, occasionally a transmission/converter would come in for repair that got hot enough to actually melt the aluminum stator. The stink would linger in the building for hours!!

There are no ďnewĒ converters being made. All the aftermarket converters start life usually as fwd 4 cylinder converters. The 245mm (usually referred to as 10 inch) are commonly built from 4T60 like what is found in Buick park avenues, Chevy Malibu, etc. The converters are cut part on special lathes, the individual parts are modified, sprags and stators are adapted from other bigger converters, the turbines/pumps/stators are modified or replaced with other parts that have the fins at different angles, all to give the desired stall speed. It takes a lot of modifications to make a converter designed to go behind a 200hp engine, and have it live reliably with 5 times the power. Itís amazing if you think about it. Those modifications and machine work takes lots of time, and time is money.

#19

Sorry to hear about your misfortune Chasman414.

Please keep us informed of what you find. Are you sending the converter to Coan (or elsewhere )to have it cut open and examined?

If the converter isn't ballooned.... I am spitballing here and assume you already have done the following:

Did you pull the pump out of the Th400 to inspect the drive lugs on the gears and everything in it for the Pressure regulator to make sure it isn't stuck? Did you closely inspect the pump drive notches on the converter nose?

Also, did you look closely at the bellhousing of the trans to make sure it doesn't have a crack that might have allowed flex during a high pressure event like releasing the brake where the converter could pop out and stand on the pump drive lugs?

Matt69OLDS is an awesome resource of knowledge here, and we are lucky to have him on our forum.

Please keep us informed of what you find. Are you sending the converter to Coan (or elsewhere )to have it cut open and examined?

If the converter isn't ballooned.... I am spitballing here and assume you already have done the following:

Did you pull the pump out of the Th400 to inspect the drive lugs on the gears and everything in it for the Pressure regulator to make sure it isn't stuck? Did you closely inspect the pump drive notches on the converter nose?

Also, did you look closely at the bellhousing of the trans to make sure it doesn't have a crack that might have allowed flex during a high pressure event like releasing the brake where the converter could pop out and stand on the pump drive lugs?

Matt69OLDS is an awesome resource of knowledge here, and we are lucky to have him on our forum.

#20

This converter has balloon plates. See the solid plate welded to the neck, and covers the dip in the cover?

This converter has no ballon plates. Notice the dip under the hub.

The ballon plate basically prevents the converter from stretching and trying to force the engine and transmission apart. Some manufacturers build the rear covers from a chunk of steel, or on small diameter converter they will use fabricated mounts welded to the rear cover, anything to stiffen the body.

If your engine makes 550 hp, and you set the transbrake and stand on the throttle, that 550 hp is still there. Instead of moving the car, the power is being converted into heat. When I worked at Coan 25 years ago, occasionally a transmission/converter would come in for repair that got hot enough to actually melt the aluminum stator. The stink would linger in the building for hours!!

There are no ďnewĒ converters being made. All the aftermarket converters start life usually as fwd 4 cylinder converters. The 245mm (usually referred to as 10 inch) are commonly built from 4T60 like what is found in Buick park avenues, Chevy Malibu, etc. The converters are cut part on special lathes, the individual parts are modified, sprags and stators are adapted from other bigger converters, the turbines/pumps/stators are modified or replaced with other parts that have the fins at different angles, all to give the desired stall speed. It takes a lot of modifications to make a converter designed to go behind a 200hp engine, and have it live reliably with 5 times the power. Itís amazing if you think about it. Those modifications and machine work takes lots of time, and time is money.

#21

I just looked at the picture of your bearings. If both of those bearings are from your engine it looks like only the upper bearing is worn on the thrust ? That tells me the cap was not aligned properly when the engine was assembled. You have to get the cap set so that the crank is hitting both upper and lower thrust bearings on the back side of the bearing. Otherwise you only have half of the available thrust bearing working ?

The only time I have had a badly worn thrust it was on a small block Chevy engine that had been align honed and the cap had been cut on an angle.

Excessive line pressure will definitely cause it so the modification looks plausible.

The only time I have had a badly worn thrust it was on a small block Chevy engine that had been align honed and the cap had been cut on an angle.

Excessive line pressure will definitely cause it so the modification looks plausible.

#22

Sorry to hear about your misfortune Chasman414.

Please keep us informed of what you find. Are you sending the converter to Coan (or elsewhere )to have it cut open and examined?

If the converter isn't ballooned.... I am spitballing here and assume you already have done the following:

Did you pull the pump out of the Th400 to inspect the drive lugs on the gears and everything in it for the Pressure regulator to make sure it isn't stuck? Did you closely inspect the pump drive notches on the converter nose?

Also, did you look closely at the bellhousing of the trans to make sure it doesn't have a crack that might have allowed flex during a high pressure event like releasing the brake where the converter could pop out and stand on the pump drive lugs?

Matt69OLDS is an awesome resource of knowledge here, and we are lucky to have him on our forum.

Please keep us informed of what you find. Are you sending the converter to Coan (or elsewhere )to have it cut open and examined?

If the converter isn't ballooned.... I am spitballing here and assume you already have done the following:

Did you pull the pump out of the Th400 to inspect the drive lugs on the gears and everything in it for the Pressure regulator to make sure it isn't stuck? Did you closely inspect the pump drive notches on the converter nose?

Also, did you look closely at the bellhousing of the trans to make sure it doesn't have a crack that might have allowed flex during a high pressure event like releasing the brake where the converter could pop out and stand on the pump drive lugs?

Matt69OLDS is an awesome resource of knowledge here, and we are lucky to have him on our forum.

I did pull the converter but that's as far as I've gone so far.You guys have lead me with this as far as the trans and converter go. I know little or less about transmissions so I'm may not be sure what you are talking about. Some things I just don't know or haven't learned yet. I will look at the bell housing next. Here are some pictures of my converter. I assume these are the pump drive notches you refer to! Once again I want to thank you all for your valuable time!

#23

I just looked at the picture of your bearings. If both of those bearings are from your engine it looks like only the upper bearing is worn on the thrust ? That tells me the cap was not aligned properly when the engine was assembled. You have to get the cap set so that the crank is hitting both upper and lower thrust bearings on the back side of the bearing. Otherwise you only have half of the available thrust bearing working ?

The only time I have had a badly worn thrust it was on a small block Chevy engine that had been align honed and the cap had been cut on an angle.

Excessive line pressure will definitely cause it so the modification looks plausible.

The only time I have had a badly worn thrust it was on a small block Chevy engine that had been align honed and the cap had been cut on an angle.

Excessive line pressure will definitely cause it so the modification looks plausible.

#24

To the best of my knowledge, once a converter balloons, it stays that way. So if it measures correctly, then I would have to agree that the converter didnít ballon.

So, the mystery deepens! It takes lot of force to tear up a thrust bearing. The question: where did the force come from? (Insert Star Wars reference!) Will the converter slip into the back of the crank smoothly? No binding or hanging up on a burr? What do the pump gears look like? Any rough edges that the converter hub can hang up on?

Once the engine is back together, and the transmission gets a clean bill of health, put a line pressure gauge on the transmission. With the vacuum modulator unhooked (which simulates WOT) you might see 250-275ish in reverse, and hopefully around 180-220 in the forward gears.

The guys at Coan have forgotten more about converter design and theory than Iíll ever know. If the converter does turn out to be ok, I hate to say it, your stuck in the middle. Engine builders always blame thrust bearing wear on the transmission, the transmission people blame the engine.

Last thought, once itís all back together, before you start the engine, verify the clearance between the converter mounting pads, and the flex plate. The ideal measurement is 3/16 to maybe a 1/4 inch. Good luck!

So, the mystery deepens! It takes lot of force to tear up a thrust bearing. The question: where did the force come from? (Insert Star Wars reference!) Will the converter slip into the back of the crank smoothly? No binding or hanging up on a burr? What do the pump gears look like? Any rough edges that the converter hub can hang up on?

Once the engine is back together, and the transmission gets a clean bill of health, put a line pressure gauge on the transmission. With the vacuum modulator unhooked (which simulates WOT) you might see 250-275ish in reverse, and hopefully around 180-220 in the forward gears.

The guys at Coan have forgotten more about converter design and theory than Iíll ever know. If the converter does turn out to be ok, I hate to say it, your stuck in the middle. Engine builders always blame thrust bearing wear on the transmission, the transmission people blame the engine.

Last thought, once itís all back together, before you start the engine, verify the clearance between the converter mounting pads, and the flex plate. The ideal measurement is 3/16 to maybe a 1/4 inch. Good luck!

#25

To the best of my knowledge, once a converter balloons, it stays that way. So if it measures correctly, then I would have to agree that the converter didnít ballon.

So, the mystery deepens! It takes lot of force to tear up a thrust bearing. The question: where did the force come from? (Insert Star Wars reference!) Will the converter slip into the back of the crank smoothly? No binding or hanging up on a burr? What do the pump gears look like? Any rough edges that the converter hub can hang up on?

Once the engine is back together, and the transmission gets a clean bill of health, put a line pressure gauge on the transmission. With the vacuum modulator unhooked (which simulates WOT) you might see 250-275ish in reverse, and hopefully around 180-220 in the forward gears.

The guys at Coan have forgotten more about converter design and theory than Iíll ever know. If the converter does turn out to be ok, I hate to say it, your stuck in the middle. Engine builders always blame thrust bearing wear on the transmission, the transmission people blame the engine.

Last thought, once itís all back together, before you start the engine, verify the clearance between the converter mounting pads, and the flex plate. The ideal measurement is 3/16 to maybe a 1/4 inch. Good luck!

So, the mystery deepens! It takes lot of force to tear up a thrust bearing. The question: where did the force come from? (Insert Star Wars reference!) Will the converter slip into the back of the crank smoothly? No binding or hanging up on a burr? What do the pump gears look like? Any rough edges that the converter hub can hang up on?

Once the engine is back together, and the transmission gets a clean bill of health, put a line pressure gauge on the transmission. With the vacuum modulator unhooked (which simulates WOT) you might see 250-275ish in reverse, and hopefully around 180-220 in the forward gears.

The guys at Coan have forgotten more about converter design and theory than Iíll ever know. If the converter does turn out to be ok, I hate to say it, your stuck in the middle. Engine builders always blame thrust bearing wear on the transmission, the transmission people blame the engine.

Last thought, once itís all back together, before you start the engine, verify the clearance between the converter mounting pads, and the flex plate. The ideal measurement is 3/16 to maybe a 1/4 inch. Good luck!

#26

I also remember seeing a video about how to modify a transmission with fixed line pressure (one without a vacuum modulator) to something that only runs max line pressure at raised engine speeds. If I remember right, you drill a hole from the forward clutch feed into the reverse boost feed at the pump. I remember thinking it was a clever idea, now Iím going to have to try and find it.

#27

not a video, but a good read about TH400 pump :

http://www.ckperformance.com/images/...ut/OILPUMP.pdf

http://www.ckperformance.com/images/...ut/OILPUMP.pdf

#30

not a video, but a good read about TH400 pump :

http://www.ckperformance.com/images/...ut/OILPUMP.pdf

http://www.ckperformance.com/images/...ut/OILPUMP.pdf

#31

I'm thinking maybe of going back to foot braking. I would hate to do that because I'm just getting used to the TB, it makes for a more accurate reaction time. As always: thank you, Charlie

PS if you find any useful info please send it to me!

#32

Since you have a transbrake, you can remove the pump, forward clutch, and direct drum without valve body removal, just by supporting the trans in a bellhousing up orientation. Remove the extension housing, get a 5gallon bucket and a sturdy piece of plywood, drill a hole big enough to fit the output shaft through, homemade holding fixture!!! Drill a few extra holes in your plywood so oil can drip into the bucket.

Remove the pump bolts, there are either 6 or 8. There are 2 threaded holes in the pump for a slide hammer. They are 3/8x16 thread. One hole is around the 10 oíclock Position, the other is at the 5. If you donít have a slide hammer, you can use a 2-3 ft section of chain. Put the some 3/8 bolts thru the chain into the threaded hole of the pump, Put a long pry bar or piece of pipe thru the chain, set it on the bellhousing, and pry it with a quick jerk. The pump will pop out easily.

Remove the pump bolts, there are either 6 or 8. There are 2 threaded holes in the pump for a slide hammer. They are 3/8x16 thread. One hole is around the 10 oíclock Position, the other is at the 5. If you donít have a slide hammer, you can use a 2-3 ft section of chain. Put the some 3/8 bolts thru the chain into the threaded hole of the pump, Put a long pry bar or piece of pipe thru the chain, set it on the bellhousing, and pry it with a quick jerk. The pump will pop out easily.

#33

Since you have a transbrake, you can remove the pump, forward clutch, and direct drum without valve body removal, just by supporting the trans in a bellhousing up orientation. Remove the extension housing, get a 5gallon bucket and a sturdy piece of plywood, drill a hole big enough to fit the output shaft through, homemade holding fixture!!! Drill a few extra holes in your plywood so oil can drip into the bucket.

Remove the pump bolts, there are either 6 or 8. There are 2 threaded holes in the pump for a slide hammer. They are 3/8x16 thread. One hole is around the 10 oíclock Position, the other is at the 5. If you donít have a slide hammer, you can use a 2-3 ft section of chain. Put the some 3/8 bolts thru the chain into the threaded hole of the pump, Put a long pry bar or piece of pipe thru the chain, set it on the bellhousing, and pry it with a quick jerk. The pump will pop out easily.

Remove the pump bolts, there are either 6 or 8. There are 2 threaded holes in the pump for a slide hammer. They are 3/8x16 thread. One hole is around the 10 oíclock Position, the other is at the 5. If you donít have a slide hammer, you can use a 2-3 ft section of chain. Put the some 3/8 bolts thru the chain into the threaded hole of the pump, Put a long pry bar or piece of pipe thru the chain, set it on the bellhousing, and pry it with a quick jerk. The pump will pop out easily.

I think our discussion has led me to a probable cause. I'm almost certain the converter did not balloon but something is causing the pump to put excess PSI on the converter when the T brake is used. If I knew what I were looking for I might attempt it but I don't think I'm ready yet! When I decide what I'm going to do I will let you know. I'm sure that if I decide to tackle this myself I will need plenty of help.

#34

Chas,

Although I am normally the type that wants to do almost everything myself if it came to an automatic transmission in a race application like yours I would almost certainly get it to someone who knows what they are doing and have them take care of it. If doing it yourself would only cause a problem with the trans then I would say go for it but as you can see the damage goes further and I know you don't want to have to buy another crankshaft

If it was mine I would have ATI do it but they are close to me. I am sure if you ask around there should be someone in your area. Go over to the "class racer" forum and ask there. Those guys are brutal on parts

http://classracer.com/classforum/index.php

Although I am normally the type that wants to do almost everything myself if it came to an automatic transmission in a race application like yours I would almost certainly get it to someone who knows what they are doing and have them take care of it. If doing it yourself would only cause a problem with the trans then I would say go for it but as you can see the damage goes further and I know you don't want to have to buy another crankshaft

If it was mine I would have ATI do it but they are close to me. I am sure if you ask around there should be someone in your area. Go over to the "class racer" forum and ask there. Those guys are brutal on parts

http://classracer.com/classforum/index.php

#35

Chas,

Although I am normally the type that wants to do almost everything myself if it came to an automatic transmission in a race application like yours I would almost certainly get it to someone who knows what they are doing and have them take care of it. If doing it yourself would only cause a problem with the trans then I would say go for it but as you can see the damage goes further and I know you don't want to have to buy another crankshaft

If it was mine I would have ATI do it but they are close to me. I am sure if you ask around there should be someone in your area. Go over to the "class racer" forum and ask there. Those guys are brutal on parts

http://classracer.com/classforum/index.php

Although I am normally the type that wants to do almost everything myself if it came to an automatic transmission in a race application like yours I would almost certainly get it to someone who knows what they are doing and have them take care of it. If doing it yourself would only cause a problem with the trans then I would say go for it but as you can see the damage goes further and I know you don't want to have to buy another crankshaft

If it was mine I would have ATI do it but they are close to me. I am sure if you ask around there should be someone in your area. Go over to the "class racer" forum and ask there. Those guys are brutal on parts

http://classracer.com/classforum/index.php

Thread

Thread Starter

Forum

Replies

Last Post

young olds

Transmission

4

August 23rd, 2013 05:26 PM