Crankshaft and manual transmission

#1

Crankshaft and manual transmission

Hi,

I have a 4 speed m20 muncie with a 350. I found a "to good to be true" deal on a olds 455! Here is my question. Can the crankshaft be machined for the pilot bearing while in the motor or does it have to be removed?

I have a 4 speed m20 muncie with a 350. I found a "to good to be true" deal on a olds 455! Here is my question. Can the crankshaft be machined for the pilot bearing while in the motor or does it have to be removed?

#2

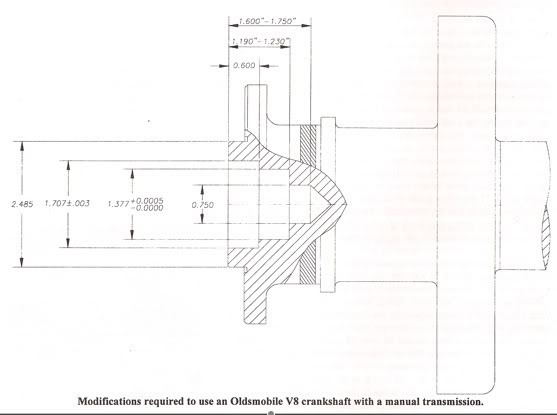

They make a "conversion" pilot bushing that goes into the hole where the torque converter pilots BUT >>>>>> if you go that route you either have to drill a hole in the crank for the trans input shaft to go into or cut off the trans input shaft so it isn't as long.

I am sure if you tried hard enough and made some type of fixture you could machine the crank in the car for the proper throwout bushing but I would imagine it being a fairly difficult job. I have done one in the lathe and it still isn't the easiest setup in the world.

I am sure if you tried hard enough and made some type of fixture you could machine the crank in the car for the proper throwout bushing but I would imagine it being a fairly difficult job. I have done one in the lathe and it still isn't the easiest setup in the world.

#4

Conversion bushing is the quickest option. The clearance hole for the nose isn't precision, so can hand-drill. This method has been around a long time. I would be worried about durability on a daily driver, but that's probably not what's happening here.

Don't try to hand-drill for a real pilot bearing - it won't go well. Gotta pull the crank and go to the machine shop for that.

Don't try to hand-drill for a real pilot bearing - it won't go well. Gotta pull the crank and go to the machine shop for that.

#5

Conversion bushing is the quickest option. The clearance hole for the nose isn't precision, so can hand-drill. This method has been around a long time. I would be worried about durability on a daily driver, but that's probably not what's happening here.

Don't try to hand-drill for a real pilot bearing - it won't go well. Gotta pull the crank and go to the machine shop for that.

Don't try to hand-drill for a real pilot bearing - it won't go well. Gotta pull the crank and go to the machine shop for that.

#6

Thread

Thread Starter

Forum

Replies

Last Post

Aceshigh

Transmission

8

January 27th, 2011 04:28 PM