measuring cylinder bore

#1

If you have a head off say a ...........455 olds and nothing is stamped on the top of the deep dish pistons stating bore size or how much over the cylinders are from new .........

What could be a quick and cheap way to find out???

Thanks

joepenoso

What could be a quick and cheap way to find out???

Thanks

joepenoso

#2

You can clean the carbon from the ridge area and measure with a dial caliper, but the only way I know to get it accurate is with a inside micrometer. If the engine is out, take it to a shop and get them to measure it.

Are you trying to figure out if it has been bored, or if it needs bored?

Are you trying to figure out if it has been bored, or if it needs bored?

#4

I agree you need to measure ................but I wonder ...........short of taking the block out to the machine shop can you use tape or ruler...finger nail to tell if the bore is stock dimension or needing to be bored.

Thanks

joepenoso

Thanks

joepenoso

#5

Again, you need to use an bore gauge or telescoping gauges with a regular micrometer to get an accurate reading! Your looking for wear at top, middle and bottom of travel points in the cylinder and out of round.

Pat

Pat

#6

You're asking whether you can measure to an accuracy within thousandths (or ten-thousandths) of an inch, in a hole, with a ruler?

You can get a good ideal of how much wear a cylinder has had by feeling the ridge at the top of the cylinder - it had no ridge when it was made, and will have some amount of a perceptible ridge with the passage of tens of thousands of miles, which will vary immensely with maintenance and type of usage, but this will not tell you about the whole bore.

Yes, if you can feel a decent ridge, it will definitely need to be bored, and if there is no ridge at all, it probably won't, especially if you are using the original pistons and rings, but these are rough ways of determining whether an old engine will run, not ways to make multi-thousand dollar rebuilding decisions.

If you are planning to change pistons, then you have to have some very good measurements if you are even considering not boring it, unless you're just planning to slap it together as an "experiment" that you don't expect to run for very long.

- Eric

#8

I'm afraid that I must disagree with this.

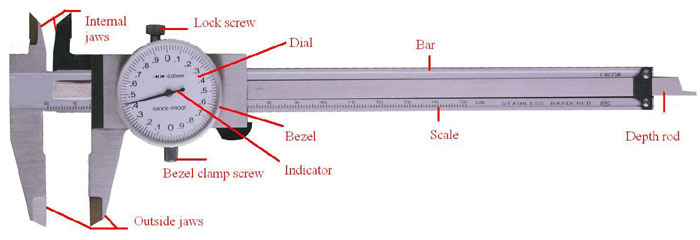

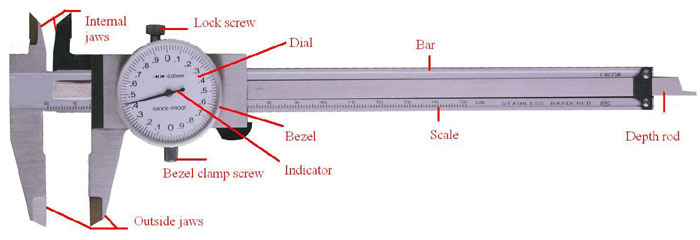

A dial caliper (or any micrometer caliper) looks like this:

The part labeled "Internal Jaws" is the part that measures "inside" spaces.

You will notice that it can only measure down about half an inch, which means that if you stick it down in the cylinder, it will measure the ridge, which is not worn, and not the bore.

You really need a bore gauge or a telescoping gauge, like these, with rounded ends to measure the bore accurately.

Well, that's a relief. I can laugh now, instead of cry.

- Eric

A dial caliper (or any micrometer caliper) looks like this:

The part labeled "Internal Jaws" is the part that measures "inside" spaces.

You will notice that it can only measure down about half an inch, which means that if you stick it down in the cylinder, it will measure the ridge, which is not worn, and not the bore.

You really need a bore gauge or a telescoping gauge, like these, with rounded ends to measure the bore accurately.

Well, that's a relief. I can laugh now, instead of cry.

- Eric

#9

Dial caliper

http://www.ebay.com/itm/0-6-STAINLES...item45eda2e7d4

which will easily tell of it's 4.126 [stock] or 4.155 [thirty over] or even larger.

"Further, Olds used 4 different sized pistons to accomodate the different bore sizes. Example: Bore A, B, C, and D. Generally, the block is stamped with the piston size near one of the head bolts. "

=================

Correct. This stamp is light and usually hard to see.

Furthermore, the factory on rare occasion used ~0.010" oversize pistons in a bore that didn't come out just right the 1st time- Bores coded J,K,L or M, I think. I have run across ONE of these in my many engine autopsies.

#10

#11

Thanks to everybody......I wanted to know if the cylinders were bored..I know I didn't express my self well but appreciate the help and explaining of the various tools shortcomings. I went out to Princess Auto and bought $20.00 dial caliper. Hopefully I will find what bore size the block is at.

thanks to all

joepenoso

thanks to all

joepenoso

#12

From Eric's picture of the bore gauge does the dial part swap onto the various bore gauge parts ? What is the dial part called, and is it a stand alone tool for measuring depth ( or distance moved) as well ?

Thanks for the pic as well I wondered how the bore was measured

Thanks for the pic as well I wondered how the bore was measured

Thread

Thread Starter

Forum

Replies

Last Post

jensenracing77

General Discussion

20

April 17th, 2012 05:08 PM