Finding TDC....

#1

Finding TDC....

Hi guys,

I have been looking around for best ways (or tools) to find TDC and it looks like the only way to be 100% accurate is with a piston stop tool. For a stock 350 Rocket in a 1971 Cutlass, does anyone have any recommendations on what tool is best? Based on what amazon has to offer, there appears to be different sizes...

Thanks,

I have been looking around for best ways (or tools) to find TDC and it looks like the only way to be 100% accurate is with a piston stop tool. For a stock 350 Rocket in a 1971 Cutlass, does anyone have any recommendations on what tool is best? Based on what amazon has to offer, there appears to be different sizes...

Thanks,

#3

I was thinking of doing something like that with a screw driver and marking the balancer when it reaches its highest level, but then I read that it becomes basically impossible to be accurate when the piston reaches the top because 5 degrees on the balancer will only move 0.007" so I could still be out by 5 or more degrees trying do do it this way.

I figure for the negligible cost to get the right tool I will just do that. It looks like I just need to get the right thread size and if I understand how this thing works, the depth into the cylinder is adjustable. If that is right then I suppose the only critical part in picking one of these out is making sure the thread size is right. I just wondered if anyone had experience with one type or brand maybe being better than another.

I figure for the negligible cost to get the right tool I will just do that. It looks like I just need to get the right thread size and if I understand how this thing works, the depth into the cylinder is adjustable. If that is right then I suppose the only critical part in picking one of these out is making sure the thread size is right. I just wondered if anyone had experience with one type or brand maybe being better than another.

#6

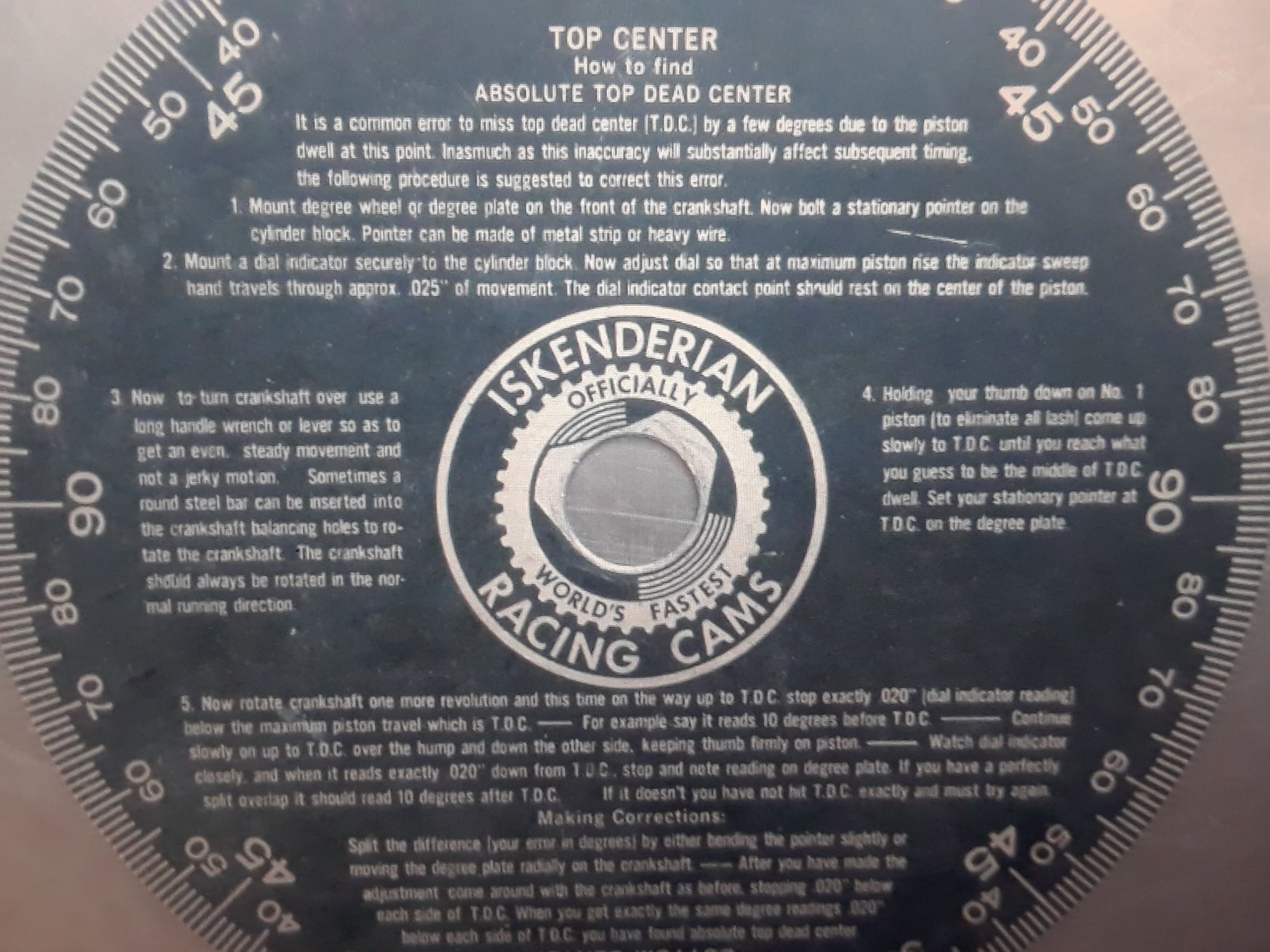

The tool Charlie Jones has shown is the best way of accurately determining tdc, but you can fabricate a tool to do the job, a degree wheel as used is tightening modern cylinder head bolts can be adapted. or even a pointer on the crankshaft with a marker and stiff paper or card will work. Unless you know exactly where tdc is on your engine you can never be certain your camshaft and ignition timing are spot on.

Roger.

Roger.

#7

So the first question is, WHY are you trying to determine TDC? Are you trying to degree a cam? Are you trying to check the accuracy of the timing mark on the balancer? Or are you simply trying to install a distributor? If the latter, then "close" is more than good enough. I've used a wad of paper towel in the no. 1 spark plug hole. Bump the starter and when the wad is ejected, that's close enough to install the distributor to get it to fire. If your reason is one of the first two, then a piston stop is the ONLY way to do this. Turn the engine one way until you contact the stop and mark the balancer (or note the degree wheel marking). Turn it the other way and do the same. Split the difference and that's TDC.

#8

Hi Joe,

It is to verify the timing mark on the balancer. I want to be sure the timing is right but have read that the balancer can slip. So, I figure before I go adjusting the timing based on a mark that may be wrong I will confirm that first.

I actually found a piston stop locally so I am going to pick that up at lunch today and see what I can do after work. It is for 14mm thread diameters so I am sure it will work. Being the only one available (at least that I can find) in this city I can't be picky, lol. I am actually hoping that where this tool determines TDC to be is different than where the factory mark is. That would possibly explain why it seems like the timing is out even though the timing light and dwell angle meter both say I'm good.

It is to verify the timing mark on the balancer. I want to be sure the timing is right but have read that the balancer can slip. So, I figure before I go adjusting the timing based on a mark that may be wrong I will confirm that first.

I actually found a piston stop locally so I am going to pick that up at lunch today and see what I can do after work. It is for 14mm thread diameters so I am sure it will work. Being the only one available (at least that I can find) in this city I can't be picky, lol. I am actually hoping that where this tool determines TDC to be is different than where the factory mark is. That would possibly explain why it seems like the timing is out even though the timing light and dwell angle meter both say I'm good.

#9

#10

No, I more meant that in terms of the car being tuned properly, the dwell angle meter says about 30.5 degrees and the timing, based on its current mark show 12 degrees at 1100 RPM right where the factory spec says, but it doesn't run that great. I know there very well could be other issues and that there are possibly better ways and settings to use to time it, but I just want to rule out TDC being wrong before going too far in another direction.

It still has only about 15.75" of vacuum and I have replaced all rubber hoses with new, added some plugs to some open ports, and my neighbor showed me an apparent way to try and find vacuum leaks using an unlit propane torch. Apparently when the engine sucks the propane through instead of air it will change the RPM and help zero in on leaks. We put it around the carb base and the intake manifold where it meets with the heads but nothing seemed to be going on there.

I will get to playing around with the timing soon and I am hoping that turning the distributor will smooth the engine out and raise the vacuum. If not, I don't know what is left...

It still has only about 15.75" of vacuum and I have replaced all rubber hoses with new, added some plugs to some open ports, and my neighbor showed me an apparent way to try and find vacuum leaks using an unlit propane torch. Apparently when the engine sucks the propane through instead of air it will change the RPM and help zero in on leaks. We put it around the carb base and the intake manifold where it meets with the heads but nothing seemed to be going on there.

I will get to playing around with the timing soon and I am hoping that turning the distributor will smooth the engine out and raise the vacuum. If not, I don't know what is left...

#11

My daughters go through too much toilet paper so... When my fingers aren't being used, I stick one over #1 plug hole to find TDC when setting my distributor in and timing it.

So if it were me in your case,

I would probably begin with pulling the distributor cap off, put a socket on the crank, check for backlash on the chain. Then worry about nailing down everything else.

But that's just me..

Eric

So if it were me in your case,

I would probably begin with pulling the distributor cap off, put a socket on the crank, check for backlash on the chain. Then worry about nailing down everything else.

But that's just me..

Eric

#12

So the first question is, WHY are you trying to determine TDC? Are you trying to degree a cam? Are you trying to check the accuracy of the timing mark on the balancer? Or are you simply trying to install a distributor? If the latter, then "close" is more than good enough. I've used a wad of paper towel in the no. 1 spark plug hole. Bump the starter and when the wad is ejected, that's close enough to install the distributor to get it to fire. If your reason is one of the first two, then a piston stop is the ONLY way to do this. Turn the engine one way until you contact the stop and mark the balancer (or note the degree wheel marking). Turn it the other way and do the same. Split the difference and that's TDC.

Rick

#13

Joe - Will the paper towel method work on a 1956 -324? Reading different information I have tried feeling compression on #1 then locating the mark. In other information I read to feel when it blows your finger away. I want to install a distributor. Thanks for any help.

Rick

Rick

Thread

Thread Starter

Forum

Replies

Last Post