Engine rebuild?

#1

Engine rebuild?

Hey guys,

Iím sure this question has been asked a thousand times, but I would like to know what you all think for my situation. 68 Cutlass S, 350. All original engine, not a single thing has been done to it. Literally nothing, not even a valve cover gasket swap, diddly squat. Engine has 95k miles.

The other day I was at a stoplight, engine cut off, couldn't get it started. Discovered the timing chain had slipped on the timing gear (thanks GM engineers for nylon gears) and I believe it bent a few of the valves in the process.

Now I know some people will say just replace valves and rebuild heads, put them back and let it roll on. But Iíve also heard other opinions about it saying that doing a top end job will make the bottom end ďweakerĒ per say, but does it really matter? Personally, I assumed with almost 100k miles and not a thing on the engine being replaced, that a full rebuild would make sense but also donít want to spend money if thereís no reason for it.

I would like to have something reliable that I could drive to work 2-3 times a week and maybe a road trip or 2 though out the year, not being super concerned about being stranded. Iíd like a little more power out of the engine anyways personally (is now a 2 barrel, stock exhaust manifolds, but has 5 heads) and figured that if ANYTHING at all was off internally, maybe a rebuild would be a good way for me to go.

Just let me know what you all think! Thanks

Pat

UPDATE

So did a compression test today for the hell of it, hereís what I found

#1- 0

#2- 130

#3- 0

#4- 0

#5- 155

#6- 165

#7-130

#8- +/- 30

Now I know that basically 0 in 4 out of 8 cylinder is horrendous, but any ideas of why that would be happening. Kind of a newbie to engine work, so any advice is appreciated. Thanks!

Pat

Iím sure this question has been asked a thousand times, but I would like to know what you all think for my situation. 68 Cutlass S, 350. All original engine, not a single thing has been done to it. Literally nothing, not even a valve cover gasket swap, diddly squat. Engine has 95k miles.

The other day I was at a stoplight, engine cut off, couldn't get it started. Discovered the timing chain had slipped on the timing gear (thanks GM engineers for nylon gears) and I believe it bent a few of the valves in the process.

Now I know some people will say just replace valves and rebuild heads, put them back and let it roll on. But Iíve also heard other opinions about it saying that doing a top end job will make the bottom end ďweakerĒ per say, but does it really matter? Personally, I assumed with almost 100k miles and not a thing on the engine being replaced, that a full rebuild would make sense but also donít want to spend money if thereís no reason for it.

I would like to have something reliable that I could drive to work 2-3 times a week and maybe a road trip or 2 though out the year, not being super concerned about being stranded. Iíd like a little more power out of the engine anyways personally (is now a 2 barrel, stock exhaust manifolds, but has 5 heads) and figured that if ANYTHING at all was off internally, maybe a rebuild would be a good way for me to go.

Just let me know what you all think! Thanks

Pat

UPDATE

So did a compression test today for the hell of it, hereís what I found

#1- 0

#2- 130

#3- 0

#4- 0

#5- 155

#6- 165

#7-130

#8- +/- 30

Now I know that basically 0 in 4 out of 8 cylinder is horrendous, but any ideas of why that would be happening. Kind of a newbie to engine work, so any advice is appreciated. Thanks!

Pat

Last edited by patkep3; October 29th, 2019 at 08:13 AM. Reason: Update

#2

Did it burn any oil prior to failing? If it ran good before you may get away with just doing the cam chain and valves. However imo it would be foolish not to do a complete rebuild at this time. The valves hitting the pistons wont have done them any good. Also at 100k it wont be that long until a full rebuild is necessary anyways.

#3

New 4 barrel intake.........stock or after market with a Quadrajet would be easy. New cam gear and roller chain, valves, valve job are a must. From there, its how much money do you want to spend. A full overhaul wouldn't be a bad idea. Others will chime in with their opinions. Get someone who is familiar with Oldsmobile engines.

#4

Replace the old chain and gears with new. At this point without reinstalling the front cover, disconnect the coil and do a leakdown or a compression test. If it is good then a rebuild won't improve anything unless you put performance upgrades such as pistons and camshaft, four barrel, dual exhaust...

If the test result is good you could remove the oil pan to clean out the plastic from the cam gear, regasket the motor and drive for many, many more miles. There is a good chance that valves did not bend; but, you won't know until after the leakdown or compression test. Since it is a two barrel with dished pistons vs. high compression pistons decreases the likelihood of bent valves.

Good luck!!!

If the test result is good you could remove the oil pan to clean out the plastic from the cam gear, regasket the motor and drive for many, many more miles. There is a good chance that valves did not bend; but, you won't know until after the leakdown or compression test. Since it is a two barrel with dished pistons vs. high compression pistons decreases the likelihood of bent valves.

Good luck!!!

#5

I doubt that the valves hit the pistons. A 350 2v has "soup bowl" pistons, deep dish. I would bet you have neoprene in the oil pan and the pickup screen will have some in it. I've seen the screen packed with neoprene on a running engine that someone replaced the timing set without pulling then pan. It was a tired engine but ran ok but smoked. I said "there goes to myth Oldsmobiles has an oiling problem." Dropping the pan with the engine in the car is a b*tch, if you have a lift that makes it a lot easier. Without a car lift, I'd pull the engine. Put the engine on a engine stand and pull the oil pan BEFORE rotating the engine. You'll find out about MAW, Might As Well while the engine is out or Might As Well while the engine is on the stand. Good luck

#6

Good time to go through the engine. As said, bent valves are unlikely. But have the heads gone through with a fresh multiple angle job, new stem seals, maybe a bowl hog under the valves, upgrade the valve springs, add a more aggressive camshaft, check the cylinder wear and bearing condition. Now is a good time to replace the pan gasket, to clean out the chunks and upgrade to the rubber 2 piece rear main seal.

#7

New 4 barrel intake.........stock or after market with a Quadrajet would be easy. New cam gear and roller chain, valves, valve job are a must. From there, its how much money do you want to spend. A full overhaul wouldn't be a bad idea. Others will chime in with their opinions. Get someone who is familiar with Oldsmobile engines.

If you decide to go for a complete rebuild, be sure to get the right pistons or you could end up with a lot less compression than you already have. Post questions here on the board and folks will get you to the right parts.

#8

Until you fix the timing chain, a compression test is meaningless. You can MIGHTASWELL yourself into a body-off restoration. Unless you're looking for an excuse to build the motor, put on the new chain and THEN do a compression test. I suspect you will find that the engine will run again at that point.

#9

Did it burn any oil prior to failing? If it ran good before you may get away with just doing the cam chain and valves. However imo it would be foolish not to do a complete rebuild at this time. The valves hitting the pistons wont have done them any good. Also at 100k it wont be that long until a full rebuild is necessary anyways.

Honestly not that I ever noticed, and I 100% agree with you. Most definitely leaning towards at least going though everything and checking it out. Rings just as preventive maintenance, Iíll also check bearings and crank wear while Iím at it.

#10

New 4 barrel intake.........stock or after market with a Quadrajet would be easy. New cam gear and roller chain, valves, valve job are a must. From there, its how much money do you want to spend. A full overhaul wouldn't be a bad idea. Others will chime in with their opinions. Get someone who is familiar with Oldsmobile engines.

#11

Replace the old chain and gears with new. At this point without reinstalling the front cover, disconnect the coil and do a leakdown or a compression test. If it is good then a rebuild won't improve anything unless you put performance upgrades such as pistons and camshaft, four barrel, dual exhaust...

If the test result is good you could remove the oil pan to clean out the plastic from the cam gear, regasket the motor and drive for many, many more miles. There is a good chance that valves did not bend; but, you won't know until after the leakdown or compression test. Since it is a two barrel with dished pistons vs. high compression pistons decreases the likelihood of bent valves.

Good luck!!!

If the test result is good you could remove the oil pan to clean out the plastic from the cam gear, regasket the motor and drive for many, many more miles. There is a good chance that valves did not bend; but, you won't know until after the leakdown or compression test. Since it is a two barrel with dished pistons vs. high compression pistons decreases the likelihood of bent valves.

Good luck!!!

Thanks! Will absolutely know more about what has to be done once I yank it out, but will keep everyone updated.

#12

I doubt that the valves hit the pistons. A 350 2v has "soup bowl" pistons, deep dish. I would bet you have neoprene in the oil pan and the pickup screen will have some in it. I've seen the screen packed with neoprene on a running engine that someone replaced the timing set without pulling then pan. It was a tired engine but ran ok but smoked. I said "there goes to myth Oldsmobiles has an oiling problem." Dropping the pan with the engine in the car is a b*tch, if you have a lift that makes it a lot easier. Without a car lift, I'd pull the engine. Put the engine on a engine stand and pull the oil pan BEFORE rotating the engine. You'll find out about MAW, Might As Well while the engine is out or Might As Well while the engine is on the stand. Good luck

#13

Good time to go through the engine. As said, bent valves are unlikely. But have the heads gone through with a fresh multiple angle job, new stem seals, maybe a bowl hog under the valves, upgrade the valve springs, add a more aggressive camshaft, check the cylinder wear and bearing condition. Now is a good time to replace the pan gasket, to clean out the chunks and upgrade to the rubber 2 piece rear main seal.

#14

I agree with this since you are looking for more power. The 2bbl engines had 9:1 compression so that would be good for a mild camshaft upgrade along with a 4bbl carb.

If you decide to go for a complete rebuild, be sure to get the right pistons or you could end up with a lot less compression than you already have. Post questions here on the board and folks will get you to the right parts.

If you decide to go for a complete rebuild, be sure to get the right pistons or you could end up with a lot less compression than you already have. Post questions here on the board and folks will get you to the right parts.

#15

Until you fix the timing chain, a compression test is meaningless. You can MIGHTASWELL yourself into a body-off restoration. Unless you're looking for an excuse to build the motor, put on the new chain and THEN do a compression test. I suspect you will find that the engine will run again at that point.

#16

Yah, the factory rear main seal is a two piece rope seal. The rigid rubber seal is much easier to remove and install. Some claim the replacement rope seals aren't as good as they once were due to the removal of asbestos from them.

#17

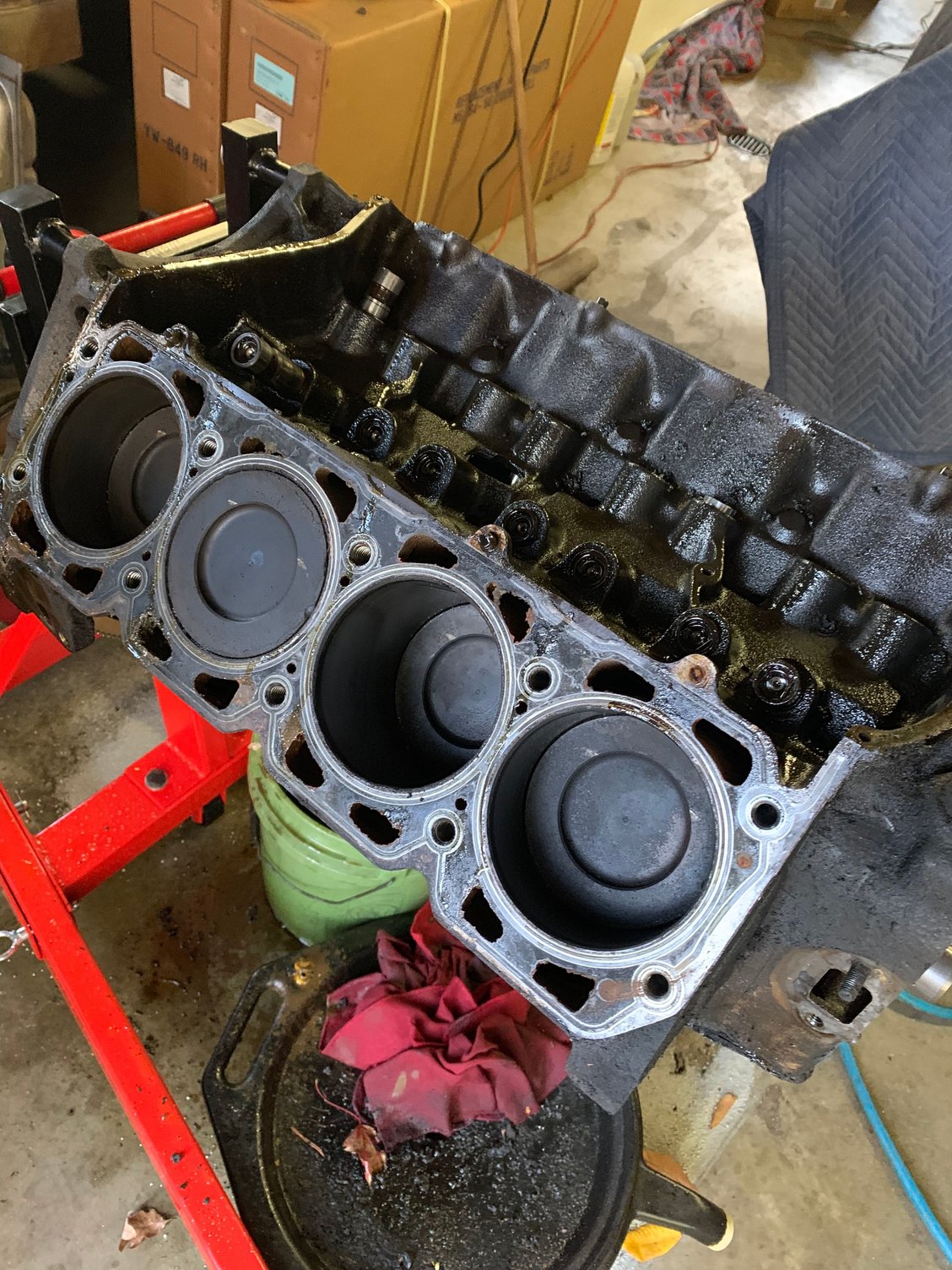

I was moving a 1967 400 E block project engine that I picked up last year. It was missing the carburetor and the heads off but mostly there. I pulled the short block apart. One piston had cracked ring glands. (Detonation?) Neoprene off cam gear, probably jumped. The crankshaft is std/std and journals ok but bearings worn. (Thin) I'm pretty sure oil changes were few and far between. Still has a Hastings filter, I may open it up. The oil pump screen fits right into this thread. I tapped it and and here's what came out of the screen. Notice the cardboard says "fragile", when I talk Oldsmobiles I pronounce that word the way the(Christmas Story) Father (Oldsmobile man) pronouns it, fra-gil-ee.

Last edited by Kennybill; October 31st, 2019 at 05:46 PM. Reason: Forget 2 words

#18

I was moving a 1967 400 E block project engine that I picked up last year. It was missing the carburetor and the heads off but mostly there. I pulled the short block apart. One piston had cracked ring glands. (Detonation?) Neoprene off cam gear, probably jumped. The crankshaft is std/std and journals ok but bearings worn. (Thin) I'm pretty sure oil changes were few and far between. Still has a Hastings filter, I may open it up. The oil pump screen fits right into this thread. I tapped it and and here's what came out of the screen. Notice the cardboard says "fragile", when I talk Oldsmobiles I pronounce that word the way the Father (Oldsmobile man) pronouns it, fra-gil-ee.

Wow! Yeah whoever thought it was a good idea to put plastic gears on the cam gear should be punched in the face lol. Iíve heard oil changes are more important on these engines compared to others due to the rear return drains in the heads clog pretty easily. Grandpa bought mine new in 68 and religiously changed the oil at max every 3k miles, and it STILL had sludge in them.. I canít even imagine an engine where oil changes weren't a priority. On mine, will definitely change out cam bearings just so the new cam has something fresh to start on, and most likely crank bearings too just as a preventive thing.

#19

Cool! Iíll be replacing that so Iíll definitely keep that in mind.

#20

As said replace the timing chain. The only double roller set I would buy is the Cloyes Billet roller 9 way timing set. It is around $100 or you can buy a basic replacement set, your call. It could also be valve sealing issues with that low of compression on so many cylinders. You won't know for sure till the timing chain is done.

#21

As said replace the timing chain. The only double roller set I would buy is the Cloyes Billet roller 9 way timing set. It is around $100 or you can buy a basic replacement set, your call. It could also be valve sealing issues with that low of compression on so many cylinders. You won't know for sure till the timing chain is done.

#22

Some do, most don't. No issues with the Cloyes Street double roller timing set. I used it on a 403 and transfered to my 350. The chain on it fits like garbage, the billet roller set is much better and will be going on the 403.

#23

#24

I have read that folks who had clearance issues would open up the mounting holes on the pump a bit and that provided adequate clearance.

#25

I was in that situation recently with a newer car. Mine being front wheel drive elected to just have a valve job done on the heads and replaced the timing chain. I think if I had yours I would have overhauled the entire engine. It's not that much more work.

#26

#27

#29

#30

It's a wonder an engine runs from the sludge. Every engine I've been in was packed solid. I also have never removed a GM hydraulic lifter that wasn't froze up. After rebuilding the engine in my Chev van I've started changing the oil monthly since I'm always in stop and go traffic.

#31

It's a wonder an engine runs from the sludge. Every engine I've been in was packed solid. I also have never removed a GM hydraulic lifter that wasn't froze up. After rebuilding the engine in my Chev van I've started changing the oil monthly since I'm always in stop and go traffic.

#32

My "secret" ingredient is kerosene and various size brushes/wire and parts cleaning type. I mount a "totes" type plastic bin under the engine. Do the outside of the block last, degrease the outside then mask and paint the outside or it will rust. While doing this, throw new freeze (soft) plugs in it.

#33

My "secret" ingredient is kerosene and various size brushes/wire and parts cleaning type. I mount a "totes" type plastic bin under the engine. Do the outside of the block last, degrease the outside then mask and paint the outside or it will rust. While doing this, throw new freeze (soft) plugs in it.

Thread

Thread Starter

Forum

Replies

Last Post