Upgrading a Batten Headed 455 originally built by Joe Mondello 20+ years ago

#1

Upgrading a never-ran Batten Headed 455 built by Joe Mondello 20+ years ago

Hello all,

My Dad and I are the owners of a 455 that was built by Joe Mondello over 20+ years ago, and it was sitting in a crate ever since it was built and sealed and has never been run.

As a background, I have built somewhere around 50 race and street engines of all types, but only street Oldsmobile engines with ~400 hp or so. My forte is really high horsepower Subaru builds, with a mix of Big Block Mopars and LS engines as well. My best friend owned a full performance machine shop, so I got to do a lot with him and built and sold engines to others. That was 15 years ago now....

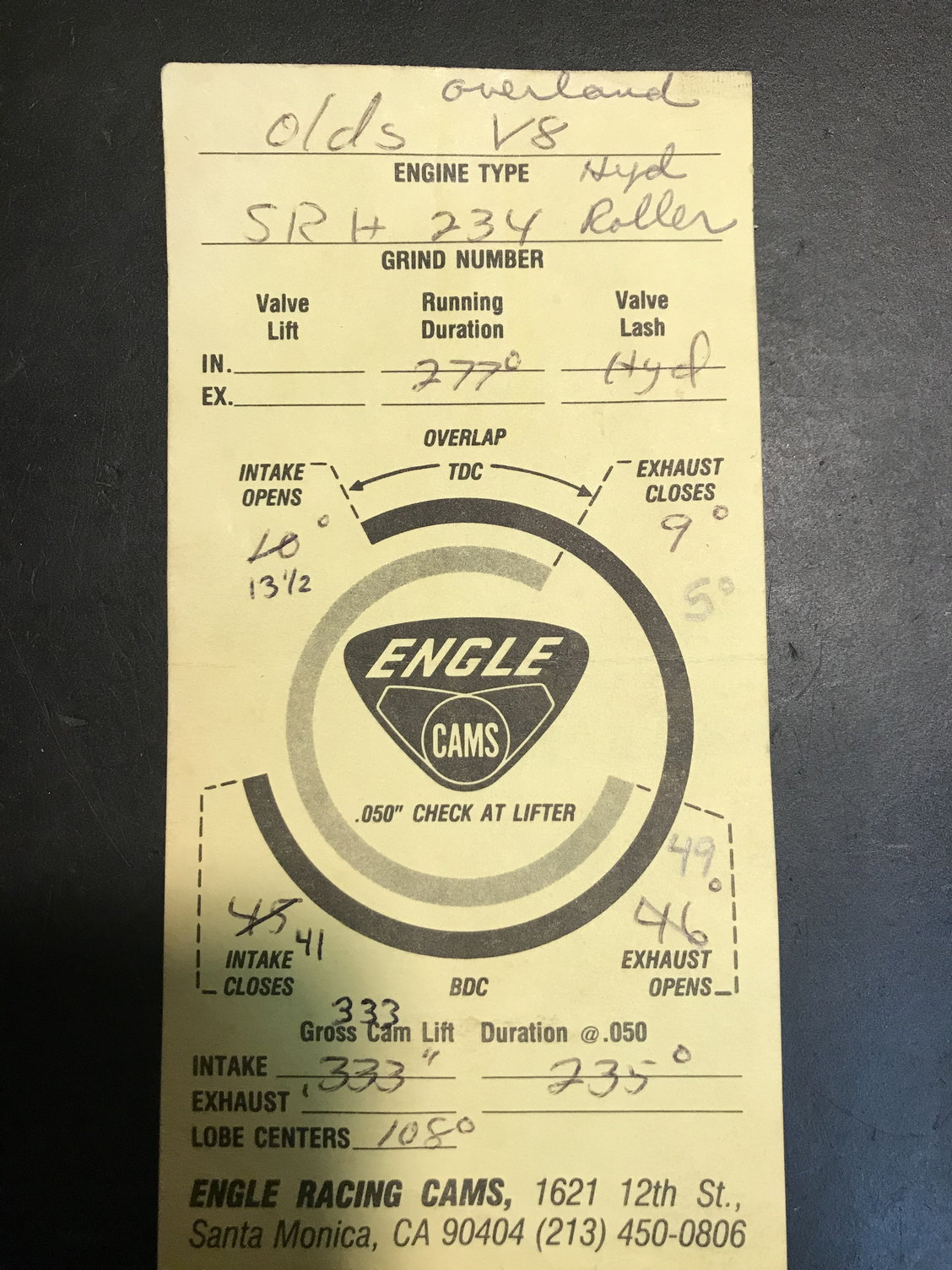

This engine has very nicely ported Iron Batten heads with the aluminum adapters for the intake, 2250 .060 over Arias pistons with (need to look at the build sheet), a forged 455 crank, beam polished rods, a Hydraulic roller cam setup with an Engle cam that specs out at 235/235 @.050 with .532/.532 lift and 108 degree lobe separation, factory-style degreed damper, factory-style flexplate, a Moroso 7 qt. pan, high volume pump with large pickup tube.

This is going in a mostly street/ Pro-Touring/some-strip 1967 Olds Cutlass 2dr. Hardtop with a 400 trans, 2800 converter, 3.73 12 Bolt Chevrolet rear with all the good stuff, adjustable upper A-arms and poly bushing lower boxed arms. We also have a Professional Products dual plane intake with the fuel injection rail kit that we plan on running, hopefully it won't choke the heads out... We have a Motec M8 fuel injection unit and harness that we will be utilizing for this setup, along with 43lb Bosch Green Giant fuel injectors. We also have a set of custom American Racing Headers with 1 7/8 primaries and 3 inch collectors with custom stainless Batten flanges. We also have a 4 inch bolt-on cowl hood, so induction height isn't a problem.

This car is in Denver, near Bandimere drag strip, at 5,500 ft+ elevation

We have been test-fitting the engine and headers which need only minor adjustment because the tubes barely hit the crossmember (number 3) and firewall (number 7). This is not ARH's fault, because they don't sell a Batten-flanged header yet....

Here are my current concerns and thoughts about the engine:

1. There was an intake mounted to the engine originally, and even though it was carefully removed, my Dad didn't seal off the intake runners well enough and gasket debris and what feels like metal shavings have fallen down the open intake valves and are sitting on the back of the closed intake valves. I obviously wouldn't want to start a new engine or an old one with metal particles waiting to go inside or already there, so a tear-down is going to have to occur.

2. Because we are going to run fuel injection, and because we need as much compression as possible here at this elevation, we are thinking about a different Hydraulic Roller cam with 112-114 degree lobe separation, and possibly upping the duration into the mid 240's on the intake and 250's on the exhaust at .050 with ~ .600+ lift. Also, if we are going to change it anyways, might as well make more power, right?

I am not sure what the true compression is..... I will find out soon when I pull the heads off.

Anyone here with high-altitude cam timing experience ?

3. After reading too many horror stories about the stock or reworked connecting rods failing or causing failures, I think we are going to buy some form of H Beam aftermarket rods, but I haven't settled for sure. Also, if using a stock 4.250 stroke crank, if I wanted to use GRP aluminum rods, will that require notching the bottom of the cylinder bores? I don't know if the stock rods were bushed for floating pins or not, but I would assume that the Arias pistons would have provisions for locks (I hope).

4. I am wondering if we should replace the degreed balancer for an ATI SFI approved one and also Replace the Flexplate for an SFI approved one as well. I don't think we really plan on going above 6,000 rpm, but, with a good enough bottom end and enough airflow, it is possible. Thoughts?

5. Head gasket replacement - I am betting this was assembled with a fel-pro or other fiber/steel composite head gaskets, and I am thinking this is another place/way that I can up the compression. What head gaskets do Olds builders like lately that are thinner than .040 that seems to be the standard? I have used cometics with good results on lots of other engines that I have built, but I haven't tried them on an Olds.

6. Balance rotating assembly.... I know that this will be required, again...... My next thought is, should I switch it all to internal balance?

Thanks in advance for your ideas and experience

My Dad and I are the owners of a 455 that was built by Joe Mondello over 20+ years ago, and it was sitting in a crate ever since it was built and sealed and has never been run.

As a background, I have built somewhere around 50 race and street engines of all types, but only street Oldsmobile engines with ~400 hp or so. My forte is really high horsepower Subaru builds, with a mix of Big Block Mopars and LS engines as well. My best friend owned a full performance machine shop, so I got to do a lot with him and built and sold engines to others. That was 15 years ago now....

This engine has very nicely ported Iron Batten heads with the aluminum adapters for the intake, 2250 .060 over Arias pistons with (need to look at the build sheet), a forged 455 crank, beam polished rods, a Hydraulic roller cam setup with an Engle cam that specs out at 235/235 @.050 with .532/.532 lift and 108 degree lobe separation, factory-style degreed damper, factory-style flexplate, a Moroso 7 qt. pan, high volume pump with large pickup tube.

This is going in a mostly street/ Pro-Touring/some-strip 1967 Olds Cutlass 2dr. Hardtop with a 400 trans, 2800 converter, 3.73 12 Bolt Chevrolet rear with all the good stuff, adjustable upper A-arms and poly bushing lower boxed arms. We also have a Professional Products dual plane intake with the fuel injection rail kit that we plan on running, hopefully it won't choke the heads out... We have a Motec M8 fuel injection unit and harness that we will be utilizing for this setup, along with 43lb Bosch Green Giant fuel injectors. We also have a set of custom American Racing Headers with 1 7/8 primaries and 3 inch collectors with custom stainless Batten flanges. We also have a 4 inch bolt-on cowl hood, so induction height isn't a problem.

This car is in Denver, near Bandimere drag strip, at 5,500 ft+ elevation

We have been test-fitting the engine and headers which need only minor adjustment because the tubes barely hit the crossmember (number 3) and firewall (number 7). This is not ARH's fault, because they don't sell a Batten-flanged header yet....

Here are my current concerns and thoughts about the engine:

1. There was an intake mounted to the engine originally, and even though it was carefully removed, my Dad didn't seal off the intake runners well enough and gasket debris and what feels like metal shavings have fallen down the open intake valves and are sitting on the back of the closed intake valves. I obviously wouldn't want to start a new engine or an old one with metal particles waiting to go inside or already there, so a tear-down is going to have to occur.

2. Because we are going to run fuel injection, and because we need as much compression as possible here at this elevation, we are thinking about a different Hydraulic Roller cam with 112-114 degree lobe separation, and possibly upping the duration into the mid 240's on the intake and 250's on the exhaust at .050 with ~ .600+ lift. Also, if we are going to change it anyways, might as well make more power, right?

I am not sure what the true compression is..... I will find out soon when I pull the heads off.

Anyone here with high-altitude cam timing experience ?

3. After reading too many horror stories about the stock or reworked connecting rods failing or causing failures, I think we are going to buy some form of H Beam aftermarket rods, but I haven't settled for sure. Also, if using a stock 4.250 stroke crank, if I wanted to use GRP aluminum rods, will that require notching the bottom of the cylinder bores? I don't know if the stock rods were bushed for floating pins or not, but I would assume that the Arias pistons would have provisions for locks (I hope).

4. I am wondering if we should replace the degreed balancer for an ATI SFI approved one and also Replace the Flexplate for an SFI approved one as well. I don't think we really plan on going above 6,000 rpm, but, with a good enough bottom end and enough airflow, it is possible. Thoughts?

5. Head gasket replacement - I am betting this was assembled with a fel-pro or other fiber/steel composite head gaskets, and I am thinking this is another place/way that I can up the compression. What head gaskets do Olds builders like lately that are thinner than .040 that seems to be the standard? I have used cometics with good results on lots of other engines that I have built, but I haven't tried them on an Olds.

6. Balance rotating assembly.... I know that this will be required, again...... My next thought is, should I switch it all to internal balance?

Thanks in advance for your ideas and experience

Last edited by Battenrunner; June 20th, 2018 at 08:41 PM.

#3

I will work on getting pics of the engine as we begin the tear down. We borrowed an engine stand from a friend today, but didn't have time to mount the engine on it because of my work and because the stand was left out in the weather for years and we had to get everything freed up from rust.

BTW- I like your car!

BTW- I like your car!

#4

Hello all,

This engine has very nicely ported Iron Batten heads with the aluminum adapters for the intake, 2250 .060 over Arias pistons with (need to look at the build sheet), a forged 455 crank, beam polished rods, a Hydraulic roller cam setup with an Engle cam that specs out at 235/235 @.050 with .532/.532 lift and 108 degree lobe separation, factory-style degreed damper, factory-style flexplate, a Moroso 7 qt. pan, high volume pump with large pickup tube.

This is going in a mostly street/ Pro-Touring/some-strip 1967 Olds Cutlass 2dr. Hardtop with a 400 trans, 2800 converter, 3.73 12 Bolt Chevrolet rear with all the good stuff, adjustable upper A-arms and poly bushing lower boxed arms. We also have a Professional Products dual plane intake with the fuel injection rail kit that we plan on running, hopefully it won't choke the heads out... Use an RPM and bung it yourself if possible. Holley Street Dominator works well too. We have a Motec M8 fuel injection unit and harness that we will be utilizing for this setup, along with 43lb Bosch Green Giant fuel injectors. We also have a set of custom American Racing Headers with 1 7/8 primaries and 3 inch collectors with custom stainless Batten flanges. We also have a 4 inch bolt-on cowl hood, so induction height isn't a problem.

Here are my current concerns and thoughts about the engine:

2. Because we are going to run fuel injection, and because we need as much compression as possible here at this elevation, we are thinking about a different Hydraulic Roller cam with 112-114 degree lobe separation, and possibly upping the duration into the mid 240's on the intake and 250's on the exhaust at .050 with ~ .600+ lift. Also, if we are going to change it anyways, might as well make more power, right?

You have this backwards, you need something tighter, not wider. And I'd have the heads flowed so you can really determine how much lift would be most beneficial.

And those old green top injectors aren't the best. You may want to opt for a newer design.

I am not sure what the true compression is..... I will find out soon when I pull the heads off.

Anyone here with high-altitude cam timing experience ?

3. After reading too many horror stories about the stock or reworked connecting rods failing or causing failures, I think we are going to buy some form of H Beam aftermarket rods, Yes but I haven't settled for sure. Also, if using a stock 4.250 stroke crank, if I wanted to use GRP aluminum rods, will that require notching the bottom of the cylinder bores? I wouldn't use those, they're not as street friendly as some will lead you to believe. I don't know if the stock rods were bushed for floating pins or not, but I would assume that the Arias pistons would have provisions for locks (I hope).

4. I am wondering if we should replace the degreed balancer for an ATI SFI approved one and also Replace the Flexplate for an SFI approved one as well. I don't think we really plan on going above 6,000 rpm, but, with a good enough bottom end and enough airflow, it is possible. Thoughts?

Always a good idea, and go internal if possible

5. Head gasket replacement - I am betting this was assembled with a fel-pro or other fiber/steel composite head gaskets, and I am thinking this is another place/way that I can up the compression. What head gaskets do Olds builders like lately that are thinner than .040 that seems to be the standard? I have used cometics with good results on lots of other engines that I have built, but I haven't tried them on an Olds.

6. Balance rotating assembly.... I know that this will be required, again...... My next thought is, should I switch it all to internal balance?

This engine has very nicely ported Iron Batten heads with the aluminum adapters for the intake, 2250 .060 over Arias pistons with (need to look at the build sheet), a forged 455 crank, beam polished rods, a Hydraulic roller cam setup with an Engle cam that specs out at 235/235 @.050 with .532/.532 lift and 108 degree lobe separation, factory-style degreed damper, factory-style flexplate, a Moroso 7 qt. pan, high volume pump with large pickup tube.

This is going in a mostly street/ Pro-Touring/some-strip 1967 Olds Cutlass 2dr. Hardtop with a 400 trans, 2800 converter, 3.73 12 Bolt Chevrolet rear with all the good stuff, adjustable upper A-arms and poly bushing lower boxed arms. We also have a Professional Products dual plane intake with the fuel injection rail kit that we plan on running, hopefully it won't choke the heads out... Use an RPM and bung it yourself if possible. Holley Street Dominator works well too. We have a Motec M8 fuel injection unit and harness that we will be utilizing for this setup, along with 43lb Bosch Green Giant fuel injectors. We also have a set of custom American Racing Headers with 1 7/8 primaries and 3 inch collectors with custom stainless Batten flanges. We also have a 4 inch bolt-on cowl hood, so induction height isn't a problem.

Here are my current concerns and thoughts about the engine:

2. Because we are going to run fuel injection, and because we need as much compression as possible here at this elevation, we are thinking about a different Hydraulic Roller cam with 112-114 degree lobe separation, and possibly upping the duration into the mid 240's on the intake and 250's on the exhaust at .050 with ~ .600+ lift. Also, if we are going to change it anyways, might as well make more power, right?

You have this backwards, you need something tighter, not wider. And I'd have the heads flowed so you can really determine how much lift would be most beneficial.

And those old green top injectors aren't the best. You may want to opt for a newer design.

I am not sure what the true compression is..... I will find out soon when I pull the heads off.

Anyone here with high-altitude cam timing experience ?

3. After reading too many horror stories about the stock or reworked connecting rods failing or causing failures, I think we are going to buy some form of H Beam aftermarket rods, Yes but I haven't settled for sure. Also, if using a stock 4.250 stroke crank, if I wanted to use GRP aluminum rods, will that require notching the bottom of the cylinder bores? I wouldn't use those, they're not as street friendly as some will lead you to believe. I don't know if the stock rods were bushed for floating pins or not, but I would assume that the Arias pistons would have provisions for locks (I hope).

4. I am wondering if we should replace the degreed balancer for an ATI SFI approved one and also Replace the Flexplate for an SFI approved one as well. I don't think we really plan on going above 6,000 rpm, but, with a good enough bottom end and enough airflow, it is possible. Thoughts?

Always a good idea, and go internal if possible

5. Head gasket replacement - I am betting this was assembled with a fel-pro or other fiber/steel composite head gaskets, and I am thinking this is another place/way that I can up the compression. What head gaskets do Olds builders like lately that are thinner than .040 that seems to be the standard? I have used cometics with good results on lots of other engines that I have built, but I haven't tried them on an Olds.

6. Balance rotating assembly.... I know that this will be required, again...... My next thought is, should I switch it all to internal balance?

#5

Thanks for your tips cutlassefi, I am confused as to why you think I need a narrower lobe seperation cam with EFI and low air density, can you elaborate?

Also, these are the genuine (Not Chinese) Bosch green giants and are a newer style injector, as used on newer turbo and supercharged engines with a green plastic body part number 0280155968, not the old green plastic top with metal lower body injectors.

Also, these are the genuine (Not Chinese) Bosch green giants and are a newer style injector, as used on newer turbo and supercharged engines with a green plastic body part number 0280155968, not the old green plastic top with metal lower body injectors.

Last edited by Battenrunner; June 21st, 2018 at 07:50 AM.

#6

Thanks for your tips cutlassefi, I am confused as to why you think I need a narrower lobe seperation cam with EFI and low air density, can you elaborate?

Also, these are the genuine (Not Chinese) Bosch green giants and are a newer style injector, as used on newer turbo and supercharged engines with a green plastic body part number 0280155968, not the old green plastic top with metal lower body injectors.

Also, these are the genuine (Not Chinese) Bosch green giants and are a newer style injector, as used on newer turbo and supercharged engines with a green plastic body part number 0280155968, not the old green plastic top with metal lower body injectors.

Early and tighter builds cylinder pressure. Wider and later looses it.

And with an M8 you should be able to tune around any unsteady MAP signals due to the overlap.

And gotcha on the injectors. Rule of thumb, always use the smallest injector with the most pressure possible. It'll normally run better that way.

#7

Yeah, I know those narrow lobe sep cams do build more mid range and low end torque, and the M8 is capable, but again, I am here at high elevation, where cranking compression and running compression are much lower than at sea level, so it is messing with my head as to what is the best choice......

I guess my other concern is that we are also strongly considering running a vintage air A/C system, and I know the narrow lobe sep cam may play havoc on the idle tuning, even with the Bosch IAC and using the Motec to bump the idle up when the A/C is engaged.

I read that these Green Giants ran pretty well on the low end of the duty cycle and have a good spray pattern as well, so I hope tuning isnít too tough.... I have a surge tank that can mount the two Bosch 044ís I have as well (real ones, not Chinese fakes), so I have all the fuel volume and pressure I will ever need...

I have even considered a small shot of nitrous as well.... or possibly a supercharger of some type to get the HP in to the 650-700 range, but that will be later, if ever.... another reason for the cam lobe sep. quandary....

I have tuned an M48 Motec with big injectors before with my Subaru WRX, so I have some hands-on knowledge, but that was such a different animal than this olds, and it didnít run a/c and was at sea level.....

I also would like to see what kind of flow numbers the Batten heads are capable of, and I called a shop that I found that has a flowbench, but they no longer have a tech capable of running the bench....

my buddy has a SF-600 bench that we used to port and flow heads on all the time, but he is now 1,000 miles away from where I moved..... he also has a Heinz balancing rig....

I guess my other concern is that we are also strongly considering running a vintage air A/C system, and I know the narrow lobe sep cam may play havoc on the idle tuning, even with the Bosch IAC and using the Motec to bump the idle up when the A/C is engaged.

I read that these Green Giants ran pretty well on the low end of the duty cycle and have a good spray pattern as well, so I hope tuning isnít too tough.... I have a surge tank that can mount the two Bosch 044ís I have as well (real ones, not Chinese fakes), so I have all the fuel volume and pressure I will ever need...

I have even considered a small shot of nitrous as well.... or possibly a supercharger of some type to get the HP in to the 650-700 range, but that will be later, if ever.... another reason for the cam lobe sep. quandary....

I have tuned an M48 Motec with big injectors before with my Subaru WRX, so I have some hands-on knowledge, but that was such a different animal than this olds, and it didnít run a/c and was at sea level.....

I also would like to see what kind of flow numbers the Batten heads are capable of, and I called a shop that I found that has a flowbench, but they no longer have a tech capable of running the bench....

my buddy has a SF-600 bench that we used to port and flow heads on all the time, but he is now 1,000 miles away from where I moved..... he also has a Heinz balancing rig....

Last edited by Battenrunner; June 21st, 2018 at 09:00 PM.

#9

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Hello all,

My Dad and I are the owners of a 455 that was built by Joe Mondello over 20+ years ago, and it was sitting in a crate ever since it was built and sealed and has never been run.

As a background, I have built somewhere around 50 race and street engines of all types, but only street Oldsmobile engines with ~400 hp or so. My forte is really high horsepower Subaru builds, with a mix of Big Block Mopars and LS engines as well. My best friend owned a full performance machine shop, so I got to do a lot with him and built and sold engines to others. That was 15 years ago now....

This engine has very nicely ported Iron Batten heads with the aluminum adapters for the intake, 2250 .060 over Arias pistons with (need to look at the build sheet), a forged 455 crank, beam polished rods, a Hydraulic roller cam setup with an Engle cam that specs out at 235/235 @.050 with .532/.532 lift and 108 degree lobe separation, factory-style degreed damper, factory-style flexplate, a Moroso 7 qt. pan, high volume pump with large pickup tube.

This is going in a mostly street/ Pro-Touring/some-strip 1967 Olds Cutlass 2dr. Hardtop with a 400 trans, 2800 converter, 3.73 12 Bolt Chevrolet rear with all the good stuff, adjustable upper A-arms and poly bushing lower boxed arms. We also have a Professional Products dual plane intake with the fuel injection rail kit that we plan on running, hopefully it won't choke the heads out... We have a Motec M8 fuel injection unit and harness that we will be utilizing for this setup, along with 43lb Bosch Green Giant fuel injectors. We also have a set of custom American Racing Headers with 1 7/8 primaries and 3 inch collectors with custom stainless Batten flanges. We also have a 4 inch bolt-on cowl hood, so induction height isn't a problem.

This car is in Denver, near Bandimere drag strip, at 5,500 ft+ elevation

We have been test-fitting the engine and headers which need only minor adjustment because the tubes barely hit the crossmember (number 3) and firewall (number 7). This is not ARH's fault, because they don't sell a Batten-flanged header yet....

Here are my current concerns and thoughts about the engine:

1. There was an intake mounted to the engine originally, and even though it was carefully removed, my Dad didn't seal off the intake runners well enough and gasket debris and what feels like metal shavings have fallen down the open intake valves and are sitting on the back of the closed intake valves. I obviously wouldn't want to start a new engine or an old one with metal particles waiting to go inside or already there, so a tear-down is going to have to occur.

2. Because we are going to run fuel injection, and because we need as much compression as possible here at this elevation, we are thinking about a different Hydraulic Roller cam with 112-114 degree lobe separation, and possibly upping the duration into the mid 240's on the intake and 250's on the exhaust at .050 with ~ .600+ lift. Also, if we are going to change it anyways, might as well make more power, right?

I am not sure what the true compression is..... I will find out soon when I pull the heads off.

Anyone here with high-altitude cam timing experience ?

3. After reading too many horror stories about the stock or reworked connecting rods failing or causing failures, I think we are going to buy some form of H Beam aftermarket rods, but I haven't settled for sure. Also, if using a stock 4.250 stroke crank, if I wanted to use GRP aluminum rods, will that require notching the bottom of the cylinder bores? I don't know if the stock rods were bushed for floating pins or not, but I would assume that the Arias pistons would have provisions for locks (I hope).

4. I am wondering if we should replace the degreed balancer for an ATI SFI approved one and also Replace the Flexplate for an SFI approved one as well. I don't think we really plan on going above 6,000 rpm, but, with a good enough bottom end and enough airflow, it is possible. Thoughts?

5. Head gasket replacement - I am betting this was assembled with a fel-pro or other fiber/steel composite head gaskets, and I am thinking this is another place/way that I can up the compression. What head gaskets do Olds builders like lately that are thinner than .040 that seems to be the standard? I have used cometics with good results on lots of other engines that I have built, but I haven't tried them on an Olds.

6. Balance rotating assembly.... I know that this will be required, again...... My next thought is, should I switch it all to internal balance?

Thanks in advance for your ideas and experience

My Dad and I are the owners of a 455 that was built by Joe Mondello over 20+ years ago, and it was sitting in a crate ever since it was built and sealed and has never been run.

As a background, I have built somewhere around 50 race and street engines of all types, but only street Oldsmobile engines with ~400 hp or so. My forte is really high horsepower Subaru builds, with a mix of Big Block Mopars and LS engines as well. My best friend owned a full performance machine shop, so I got to do a lot with him and built and sold engines to others. That was 15 years ago now....

This engine has very nicely ported Iron Batten heads with the aluminum adapters for the intake, 2250 .060 over Arias pistons with (need to look at the build sheet), a forged 455 crank, beam polished rods, a Hydraulic roller cam setup with an Engle cam that specs out at 235/235 @.050 with .532/.532 lift and 108 degree lobe separation, factory-style degreed damper, factory-style flexplate, a Moroso 7 qt. pan, high volume pump with large pickup tube.

This is going in a mostly street/ Pro-Touring/some-strip 1967 Olds Cutlass 2dr. Hardtop with a 400 trans, 2800 converter, 3.73 12 Bolt Chevrolet rear with all the good stuff, adjustable upper A-arms and poly bushing lower boxed arms. We also have a Professional Products dual plane intake with the fuel injection rail kit that we plan on running, hopefully it won't choke the heads out... We have a Motec M8 fuel injection unit and harness that we will be utilizing for this setup, along with 43lb Bosch Green Giant fuel injectors. We also have a set of custom American Racing Headers with 1 7/8 primaries and 3 inch collectors with custom stainless Batten flanges. We also have a 4 inch bolt-on cowl hood, so induction height isn't a problem.

This car is in Denver, near Bandimere drag strip, at 5,500 ft+ elevation

We have been test-fitting the engine and headers which need only minor adjustment because the tubes barely hit the crossmember (number 3) and firewall (number 7). This is not ARH's fault, because they don't sell a Batten-flanged header yet....

Here are my current concerns and thoughts about the engine:

1. There was an intake mounted to the engine originally, and even though it was carefully removed, my Dad didn't seal off the intake runners well enough and gasket debris and what feels like metal shavings have fallen down the open intake valves and are sitting on the back of the closed intake valves. I obviously wouldn't want to start a new engine or an old one with metal particles waiting to go inside or already there, so a tear-down is going to have to occur.

2. Because we are going to run fuel injection, and because we need as much compression as possible here at this elevation, we are thinking about a different Hydraulic Roller cam with 112-114 degree lobe separation, and possibly upping the duration into the mid 240's on the intake and 250's on the exhaust at .050 with ~ .600+ lift. Also, if we are going to change it anyways, might as well make more power, right?

I am not sure what the true compression is..... I will find out soon when I pull the heads off.

Anyone here with high-altitude cam timing experience ?

3. After reading too many horror stories about the stock or reworked connecting rods failing or causing failures, I think we are going to buy some form of H Beam aftermarket rods, but I haven't settled for sure. Also, if using a stock 4.250 stroke crank, if I wanted to use GRP aluminum rods, will that require notching the bottom of the cylinder bores? I don't know if the stock rods were bushed for floating pins or not, but I would assume that the Arias pistons would have provisions for locks (I hope).

4. I am wondering if we should replace the degreed balancer for an ATI SFI approved one and also Replace the Flexplate for an SFI approved one as well. I don't think we really plan on going above 6,000 rpm, but, with a good enough bottom end and enough airflow, it is possible. Thoughts?

5. Head gasket replacement - I am betting this was assembled with a fel-pro or other fiber/steel composite head gaskets, and I am thinking this is another place/way that I can up the compression. What head gaskets do Olds builders like lately that are thinner than .040 that seems to be the standard? I have used cometics with good results on lots of other engines that I have built, but I haven't tried them on an Olds.

6. Balance rotating assembly.... I know that this will be required, again...... My next thought is, should I switch it all to internal balance?

Thanks in advance for your ideas and experience

in Denver with your drive train set up, tight converter and 3.73 gear. Aluminum rod is also a bad idea.

Last edited by VORTECPRO; June 22nd, 2018 at 05:05 AM.

#11

Looking over the engine blueprint specs, the bearings are set way too tight for a high performance build......

I found that the compression is assumed at 9.5:1 (which is way too low for Denver, unless I just want to run 85 octane in it all the time.....and it will be a dog)

Main clearance specs that are listed:

1 .0017

2 .0020

3 .0022

4 .0025

5 .0026

Rod clearance specs listed:

1 .0020

2 .0018

3 .0021

4 .0016

5 .0017

6 .0019

7 .0017

8 .0019

The crank has already been ground at least 10/10 (maybe more), but, I am afraid of running clearances that tight..... I have wiped out the bearings before on engines this tight....

Looks like I will be having the crank ground or micro polished a few more thousandths as well.......

I have to pull the engine apart to see what the piston specs are for the wrist pin size, and see if the pistons have provisions for locks, but are using pressed pins....

I am checking with a local crank specialist about stroking this forged crank to a 4.450 stroke, running a Big Block Chevrolet Eagle H Beam rod with 6.635 length, and keeping the pistons we have, if possible. It would be an easy way to increase the engine size, increase compression, and because we are replacing the rods anyways....... well, you know how it goes....

On the other hand, according to the Batten Heads, Inc. paperwork we received with the engine the Batten heads supposedly start at 74cc's, and they have 1/2 inch decks, and can be milled as low as 45cc's and still be stiff enough to be safe.....

So I may just stick with stock length Eagle H beams and mill the heads down.....

PROJECT SNOWBALL IS IN EFFECT!

I found that the compression is assumed at 9.5:1 (which is way too low for Denver, unless I just want to run 85 octane in it all the time.....and it will be a dog)

Main clearance specs that are listed:

1 .0017

2 .0020

3 .0022

4 .0025

5 .0026

Rod clearance specs listed:

1 .0020

2 .0018

3 .0021

4 .0016

5 .0017

6 .0019

7 .0017

8 .0019

The crank has already been ground at least 10/10 (maybe more), but, I am afraid of running clearances that tight..... I have wiped out the bearings before on engines this tight....

Looks like I will be having the crank ground or micro polished a few more thousandths as well.......

I have to pull the engine apart to see what the piston specs are for the wrist pin size, and see if the pistons have provisions for locks, but are using pressed pins....

I am checking with a local crank specialist about stroking this forged crank to a 4.450 stroke, running a Big Block Chevrolet Eagle H Beam rod with 6.635 length, and keeping the pistons we have, if possible. It would be an easy way to increase the engine size, increase compression, and because we are replacing the rods anyways....... well, you know how it goes....

On the other hand, according to the Batten Heads, Inc. paperwork we received with the engine the Batten heads supposedly start at 74cc's, and they have 1/2 inch decks, and can be milled as low as 45cc's and still be stiff enough to be safe.....

So I may just stick with stock length Eagle H beams and mill the heads down.....

PROJECT SNOWBALL IS IN EFFECT!

Last edited by Battenrunner; June 22nd, 2018 at 07:48 AM.

#13

That is what I was worried about with the balance card as well....

Sure, I know that idle quality will be ultimately dictated by cranking compression, dynamic compression, cam timing advance or retard, the ignition advance curve, injector PW/ injector timing, and fuel pressure

We are planning on running a manual master cylinder (no booster) and disc brakes on all 4 corners, so vacuum isn't really an issue..... I just have to make sure the engine doesn't chug too much when/if an A/C compressor kicks on at idle...

#14

Thanks cutlassefi,

That is what I was worried about with the balance card as well....

Sure, I know that idle quality will be ultimately dictated by cranking compression, dynamic compression, cam timing advance or retard, the ignition advance curve, injector PW/ injector timing, and fuel pressure.

HMMM UNFORTUNATELY NO IT WONT. ITíLL MOSTLY BE DETERMINED BY HAVING THE CORRECT SIZE INJECTOR, THE ECUís ABILITY TO MANAGE A SHORTER PULSE WIDTH AND WHATEVER IDLE SPARK CONTROL MOTEC HAS.

I just have to make sure the engine doesn't chug too much when/if an A/C compressor kicks on at idle...IT SHOULD HAVE AN AC MODE IN THE SOFTWARE

That is what I was worried about with the balance card as well....

Sure, I know that idle quality will be ultimately dictated by cranking compression, dynamic compression, cam timing advance or retard, the ignition advance curve, injector PW/ injector timing, and fuel pressure.

HMMM UNFORTUNATELY NO IT WONT. ITíLL MOSTLY BE DETERMINED BY HAVING THE CORRECT SIZE INJECTOR, THE ECUís ABILITY TO MANAGE A SHORTER PULSE WIDTH AND WHATEVER IDLE SPARK CONTROL MOTEC HAS.

I just have to make sure the engine doesn't chug too much when/if an A/C compressor kicks on at idle...IT SHOULD HAVE AN AC MODE IN THE SOFTWARE

Last edited by cutlassefi; June 22nd, 2018 at 05:01 PM.

#16

This crud was everywhere on the edges of the bores and it was hardened into big chunks on top of the pistons.... even more reason to tear this thing down. Typical Fel Pro 8171PT Head gaskets (.040 compressed) nice 3/8 pushrods though!

more pics including the heads will probably happen tomorrow.. these things have been very extensively ported, and I found a very fair priced local shop who will flow test them for us...

Last edited by Battenrunner; June 22nd, 2018 at 04:58 PM.

#18

Yeah, I am excited about flow testing. Nope, like I said at the first post, this engine has Arias pistons, not TRWís.

Also, I am hoping I can get the head checked for ccís on the chamber and bring a piston to him as well to check the dish ccís

Last edited by Battenrunner; June 22nd, 2018 at 06:51 PM.

#19

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Looking over the engine blueprint specs, the bearings are set way too tight for a high performance build......

I found that the compression is assumed at 9.5:1 (which is way too low for Denver, unless I just want to run 85 octane in it all the time.....and it will be a dog)

Main clearance specs that are listed:

1 .0017

2 .0020

3 .0022

4 .0025

5 .0026

Rod clearance specs listed:

1 .0020

2 .0018

3 .0021

4 .0016

5 .0017

6 .0019

7 .0017

8 .0019

The crank has already been ground at least 10/10 (maybe more), but, I am afraid of running clearances that tight..... I have wiped out the bearings before on engines this tight....

Looks like I will be having the crank ground or micro polished a few more thousandths as well.......

I have to pull the engine apart to see what the piston specs are for the wrist pin size, and see if the pistons have provisions for locks, but are using pressed pins....

I am checking with a local crank specialist about stroking this forged crank to a 4.450 stroke, running a Big Block Chevrolet Eagle H Beam rod with 6.635 length, and keeping the pistons we have, if possible. It would be an easy way to increase the engine size, increase compression, and because we are replacing the rods anyways....... well, you know how it goes....

On the other hand, according to the Batten Heads, Inc. paperwork we received with the engine the Batten heads supposedly start at 74cc's, and they have 1/2 inch decks, and can be milled as low as 45cc's and still be stiff enough to be safe.....

So I may just stick with stock length Eagle H beams and mill the heads down.....

PROJECT SNOWBALL IS IN EFFECT!

I found that the compression is assumed at 9.5:1 (which is way too low for Denver, unless I just want to run 85 octane in it all the time.....and it will be a dog)

Main clearance specs that are listed:

1 .0017

2 .0020

3 .0022

4 .0025

5 .0026

Rod clearance specs listed:

1 .0020

2 .0018

3 .0021

4 .0016

5 .0017

6 .0019

7 .0017

8 .0019

The crank has already been ground at least 10/10 (maybe more), but, I am afraid of running clearances that tight..... I have wiped out the bearings before on engines this tight....

Looks like I will be having the crank ground or micro polished a few more thousandths as well.......

I have to pull the engine apart to see what the piston specs are for the wrist pin size, and see if the pistons have provisions for locks, but are using pressed pins....

I am checking with a local crank specialist about stroking this forged crank to a 4.450 stroke, running a Big Block Chevrolet Eagle H Beam rod with 6.635 length, and keeping the pistons we have, if possible. It would be an easy way to increase the engine size, increase compression, and because we are replacing the rods anyways....... well, you know how it goes....

On the other hand, according to the Batten Heads, Inc. paperwork we received with the engine the Batten heads supposedly start at 74cc's, and they have 1/2 inch decks, and can be milled as low as 45cc's and still be stiff enough to be safe.....

So I may just stick with stock length Eagle H beams and mill the heads down.....

PROJECT SNOWBALL IS IN EFFECT!

Last edited by VORTECPRO; June 22nd, 2018 at 09:03 PM.

#20

Well, Vortecpro, not to get soft on you, but my reasoning for this refinement and worry is that this engine and this Cutlass is the last project that my Dad and I will ever get to work on... we have done many together, but this will be his last.

He has dementia and it is getting worse quickly, so I would like to get this done right and try to enjoy the car without it breaking down or being a disappointment once it is built. He is a retired social worker for the elderly and disabled, a Vietnam Vet, and most importantly, he is a wonderful person and awesome father to boot...... So I want it to be fun and impressive for him before he can no longer enjoy it. At this point, my 5 year old boy, myself, and my Dad have been working on the car lately, and I can really see the joy in my Dad's eyes when we are all together.

We have all been so low on money for so long, that this project has been around for more than 15 years..... slowly saving money and gathering parts (like this engine), have taken a long time and a lot of hard work. The money still hasn't gotten much easier, so we are still on a budget, but it just means having to put other things off for now to get our priorities taken care of.

I do appreciate your opinions.

After living here in Denver and seeing that even 10:1 engines can run fine on 85 octane, it definitely tells me that we are leaving lots of power on the table if we don't boost the compression a lot...

I would really be thrilled to see this car hit the 11's in the quarter here at high elevation, and I know my Dad would be on cloud nine if it did as well.

He has dementia and it is getting worse quickly, so I would like to get this done right and try to enjoy the car without it breaking down or being a disappointment once it is built. He is a retired social worker for the elderly and disabled, a Vietnam Vet, and most importantly, he is a wonderful person and awesome father to boot...... So I want it to be fun and impressive for him before he can no longer enjoy it. At this point, my 5 year old boy, myself, and my Dad have been working on the car lately, and I can really see the joy in my Dad's eyes when we are all together.

We have all been so low on money for so long, that this project has been around for more than 15 years..... slowly saving money and gathering parts (like this engine), have taken a long time and a lot of hard work. The money still hasn't gotten much easier, so we are still on a budget, but it just means having to put other things off for now to get our priorities taken care of.

I do appreciate your opinions.

After living here in Denver and seeing that even 10:1 engines can run fine on 85 octane, it definitely tells me that we are leaving lots of power on the table if we don't boost the compression a lot...

I would really be thrilled to see this car hit the 11's in the quarter here at high elevation, and I know my Dad would be on cloud nine if it did as well.

#21

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Well, Vortecpro, not to get soft on you, but my reasoning for this refinement and worry is that this engine and this Cutlass is the last project that my Dad and I will ever get to work on... we have done many together, but this will be his last.

He has dementia and it is getting worse quickly, so I would like to get this done right and try to enjoy the car without it breaking down or being a disappointment once it is built. He is a retired social worker for the elderly and disabled, a Vietnam Vet, and most importantly, he is a wonderful person and awesome father to boot...... So I want it to be fun and impressive for him before he can no longer enjoy it. At this point, my 5 year old boy, myself, and my Dad have been working on the car lately, and I can really see the joy in my Dad's eyes when we are all together.

We have all been so low on money for so long, that this project has been around for more than 15 years..... slowly saving money and gathering parts (like this engine), have taken a long time and a lot of hard work. The money still hasn't gotten much easier, so we are still on a budget, but it just means having to put other things off for now to get our priorities taken care of.

I do appreciate your opinions.

After living here in Denver and seeing that even 10:1 engines can run fine on 85 octane, it definitely tells me that we are leaving lots of power on the table if we don't boost the compression a lot...

I would really be thrilled to see this car hit the 11's in the quarter here at high elevation, and I know my Dad would be on cloud nine if it did as well.

He has dementia and it is getting worse quickly, so I would like to get this done right and try to enjoy the car without it breaking down or being a disappointment once it is built. He is a retired social worker for the elderly and disabled, a Vietnam Vet, and most importantly, he is a wonderful person and awesome father to boot...... So I want it to be fun and impressive for him before he can no longer enjoy it. At this point, my 5 year old boy, myself, and my Dad have been working on the car lately, and I can really see the joy in my Dad's eyes when we are all together.

We have all been so low on money for so long, that this project has been around for more than 15 years..... slowly saving money and gathering parts (like this engine), have taken a long time and a lot of hard work. The money still hasn't gotten much easier, so we are still on a budget, but it just means having to put other things off for now to get our priorities taken care of.

I do appreciate your opinions.

After living here in Denver and seeing that even 10:1 engines can run fine on 85 octane, it definitely tells me that we are leaving lots of power on the table if we don't boost the compression a lot...

I would really be thrilled to see this car hit the 11's in the quarter here at high elevation, and I know my Dad would be on cloud nine if it did as well.

I understand your thought process. I just see many people never actually get to the track building a better power plant, for me its about having fun, and surely I won't spend a fortune to run 11s, that's much less than 400 observed HP. Since the 1980s I've been involved with or seen several different Oldsmobile's that run from 10s to 12s @ Bandimere. Myself my 9.3 comp 467, peanut port heads, 228 @ .050 hyd cam, stamped rockers ran 10.90 @ 3720 @ Bandimere. Heres my point, that engine will run 11s with some minor adjustments, but make no mistake about this: the money should be going to the drive line to reach your goal.

#22

So Vortecpro, weíre going to go down this road again? You run bbcís, we run Oldsmobileís. Please donít try to compare the two.

Op- yep missed the piston description sorry but you can measure the width and depth of the dish and get a real good estimate. Then just do the math from there.

i think most of your combination is good, you just need to verify what you actually have is correct.

Op- yep missed the piston description sorry but you can measure the width and depth of the dish and get a real good estimate. Then just do the math from there.

i think most of your combination is good, you just need to verify what you actually have is correct.

Last edited by cutlassefi; June 23rd, 2018 at 05:13 AM.

#23

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

So Vortecpro, we’re going to go down this road again? You run bbc’s, we run Oldsmobile’s. Please don’t try to compare the two.

Op- yep missed the piston description sorry but you can measure the width and depth of the dish and get a real good estimate. Then just do the math from there.

i think most of your combination is good, you just need to verify what you actually have is correct.

Op- yep missed the piston description sorry but you can measure the width and depth of the dish and get a real good estimate. Then just do the math from there.

i think most of your combination is good, you just need to verify what you actually have is correct.

That engine was built a few years back, it went into a 1970 442 convertible 3.23 gear, fully loaded car with air conditioning, turbo 400. I went with the owner to the track 1 time, he ran 12.06 @ 119 MPH with 275 drag radials in full street trim, 27.80 baro 2130 feet elevation. He was 70 plus years old and became sick and we never got a chance to dial the car in.

I've built and machined and tested a few 455 Olds street driven and raced and been pretty successful with them, and NEVER have seen the carnage you have.

Last edited by VORTECPRO; June 23rd, 2018 at 05:23 AM.

#24

My last 455 Oldsmobile build:

That engine was built a few years back, it went into a 1970 442 convertible 3.23 gear, fully loaded car with air conditioning, turbo 400. I went with the owner to the track 1 time, he ran 12.06 @ 119 MPH with 275 drag radials in full street trim, 27.80 baro 2130 feet elevation. He was 70 plus years old and became sick and we never got a chance to dial the car in.

I've built and machined and tested a few 455 Olds street driven and raced and been pretty successful with them, and NEVER have seen the carnage you have.

That engine was built a few years back, it went into a 1970 442 convertible 3.23 gear, fully loaded car with air conditioning, turbo 400. I went with the owner to the track 1 time, he ran 12.06 @ 119 MPH with 275 drag radials in full street trim, 27.80 baro 2130 feet elevation. He was 70 plus years old and became sick and we never got a chance to dial the car in.

I've built and machined and tested a few 455 Olds street driven and raced and been pretty successful with them, and NEVER have seen the carnage you have.

So he ran a 12.06 with the air on OR it had AC? You havenít changed, youíre still a tool.

Last edited by cutlassefi; June 23rd, 2018 at 05:55 AM.

#25

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Sure

Engine build:

Lightened CP pistons, 1.5 1.5 3.0

Eagle rods remachined

Production crank, indexed, stroke set 4.250, counter weights cut .500 total

236 @ .050 hyd roller on a 108

Ported production heads 294 CFM @ peak, 275 CFM @ valve lift 28 inches

Modified production oil pan

Harlan Sharpe rockers

Performer RPM intake

1000 CFM AED carb

ATI balancer

10 inch Coan converter

Turbo 475 strait cut

3.23 gear

"You haven’t changed, you’re still a tool." cutlassefi

Still fast and provable without the carnage LOL

Last edited by VORTECPRO; June 23rd, 2018 at 06:27 AM.

#26

Sure

Engine build:

Lightened CP pistons, 1.5 1.5 3.0 Compression?

Eagle rods remachined

Production crank, indexed, stroke set 4.250, counter weights cut .500 total

236 @ .050 hyd roller on a 108

Ported production heads 294 CFM @ peak, 275 CFM @ valve lift 28 inches

Are these the heads that you did or the ones you tried to pass off as yours but really weren't?

Modified production oil pan

Harland Sharpe rockers

Performer RPM intake

1000 CFM AED carb

ATI balancer

10 inch Coan converter

Turbo 475 strait cut

3.23 gear

"You haven’t changed, you’re still a tool." cutlassefi

Still fast and provable without the carnage LOL

Engine build:

Lightened CP pistons, 1.5 1.5 3.0 Compression?

Eagle rods remachined

Production crank, indexed, stroke set 4.250, counter weights cut .500 total

236 @ .050 hyd roller on a 108

Ported production heads 294 CFM @ peak, 275 CFM @ valve lift 28 inches

Are these the heads that you did or the ones you tried to pass off as yours but really weren't?

Modified production oil pan

Harland Sharpe rockers

Performer RPM intake

1000 CFM AED carb

ATI balancer

10 inch Coan converter

Turbo 475 strait cut

3.23 gear

"You haven’t changed, you’re still a tool." cutlassefi

Still fast and provable without the carnage LOL

Last edited by cutlassefi; June 23rd, 2018 at 04:20 PM.

#27

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Actually I'm not a liar like you. Aren't you the same one that tried to pass off some heads as yours on ROP but they ended being done by Harold Bettis? Yeah I'm real sure that was you. You got caught redhanded in a lie. You're less than honest at the very least. So why would anyone believe what you say?

Bottom line is you cater to a different group. The majority of your customers are BBC guys who's main focus is drag racing. My customer base is largely Olds guys who don't go to the track and just want to enjoy their cars on a daily basis. Apples and oranges. Just the facts.

Have a nice day!!

Bottom line is you cater to a different group. The majority of your customers are BBC guys who's main focus is drag racing. My customer base is largely Olds guys who don't go to the track and just want to enjoy their cars on a daily basis. Apples and oranges. Just the facts.

Have a nice day!!

1. Its Harold Bettes, regular in my shop

2. I have no idea what heads your talking about

3. You asked for the specs............I gave them

4. I have no desire to have anything to do with your customer base.

5. Panos's was your customer and his experience was anything but enjoyable.

6. All the heads I post about are done by me in my shop.

https://classicoldsmobile.com/forums...flow-test.html

https://classicoldsmobile.com/forums...e-my-luck.html

Last edited by VORTECPRO; June 23rd, 2018 at 04:15 PM.

#32

Geez, derail much?

How about this for proof of crappy builders, even those who used to have a very good name, like Joe Mondello......

THANK GOD I decided to pull this engine down.

The amount of gasket shellac that was literally poured down into this engine is on the ridiculous side.... Every cylinder and every piston was literally coated with this crap, and it evan ran down into every ring pack and between every ring land. Also, to boot, we found that in place of the plug in the block that was supposed to oil the distributor gears, there was a solid plug installed with no oiling hole.......

Every Clevite 77 P series rod and main bearing had a couple of slight polished areas (likely from the dang clearances being way too tight), but the Forged 455 crank has only been turned .010/.010 so far.

There was trash in every oil galley, but I didn't see any in the assembled rotating components.

Between the crap on the rings and pistons being hard as a rock, and gumming up the rings and the cylinders and creating extreme drag, the oiling hole-less plug in the back of the block, and the way-too-tight bearings everywhere, this thing was guaranteed to be ruined shortly after starting up.

It does have ARIAS speedmaster pistons, which I took to the head shop today with the heads. We are going to have the heads milled and the guy is going to CC the chambers first to verify the compression ratio we have now. We did plate it and use the burette to verify the CC's of the piston while I was there, and it checks out at 23cc's of dish volume.

I am pretty sure we are going to send all the bearings off to have them Polydyne coated, and we are going to have the crank clearances for the bearings ground into it unless someone can really talk me into stroking this crank......... Apparently, the crank shop here is very good and very reputable and affordable.

So, I can offset-grind/stroke the Forged 455 steel crank by .200 more stroke to attain a stroke of 4.450, and I can use/modify a set of 6.635 eagle rods by narrowing the little end by .062 width, pressing in new eagle undersize wrist pin bushings, and have them honed to fit the Arias pin sizes of .980 (vs. .989-.990 of the factory BB Chevrolet size). I believe the pistons we have may clear the crank weights, but if not, the weights can be profiled by the crank shop as well.

Can someone verify if I would have to grind the block for rod bolt clearance if it was stroked?

Otherwise, if we don't stroke it, we will use the Eagle Oldsmobile replacement rods and have the crank ground for proper clearances, then internal balance it with an ATI balancer (or other quality unit) and some brand of SFI approved flexplate for internal balance.

Can anyone tell me the ins and outs of using the ATI balancer with stock pulleys, etc.; does everything line up fine, I just have to grind some extra clearance on the water pump and use a different pointer ?

Any guesses on what the extra .200 of stroke would be worth for power?

The cylinder heads are being flow tested and should be finished by Wednesday, as well as flow testing the Performance Products Hurricane EFI intake attached to the head ( I want to see how much it flows when bolted to the head, and we are going to have two ports tested to see how the lower ports flow).

How about this for proof of crappy builders, even those who used to have a very good name, like Joe Mondello......

THANK GOD I decided to pull this engine down.

The amount of gasket shellac that was literally poured down into this engine is on the ridiculous side.... Every cylinder and every piston was literally coated with this crap, and it evan ran down into every ring pack and between every ring land. Also, to boot, we found that in place of the plug in the block that was supposed to oil the distributor gears, there was a solid plug installed with no oiling hole.......

Every Clevite 77 P series rod and main bearing had a couple of slight polished areas (likely from the dang clearances being way too tight), but the Forged 455 crank has only been turned .010/.010 so far.

There was trash in every oil galley, but I didn't see any in the assembled rotating components.

Between the crap on the rings and pistons being hard as a rock, and gumming up the rings and the cylinders and creating extreme drag, the oiling hole-less plug in the back of the block, and the way-too-tight bearings everywhere, this thing was guaranteed to be ruined shortly after starting up.

It does have ARIAS speedmaster pistons, which I took to the head shop today with the heads. We are going to have the heads milled and the guy is going to CC the chambers first to verify the compression ratio we have now. We did plate it and use the burette to verify the CC's of the piston while I was there, and it checks out at 23cc's of dish volume.

I am pretty sure we are going to send all the bearings off to have them Polydyne coated, and we are going to have the crank clearances for the bearings ground into it unless someone can really talk me into stroking this crank......... Apparently, the crank shop here is very good and very reputable and affordable.

So, I can offset-grind/stroke the Forged 455 steel crank by .200 more stroke to attain a stroke of 4.450, and I can use/modify a set of 6.635 eagle rods by narrowing the little end by .062 width, pressing in new eagle undersize wrist pin bushings, and have them honed to fit the Arias pin sizes of .980 (vs. .989-.990 of the factory BB Chevrolet size). I believe the pistons we have may clear the crank weights, but if not, the weights can be profiled by the crank shop as well.

Can someone verify if I would have to grind the block for rod bolt clearance if it was stroked?

Otherwise, if we don't stroke it, we will use the Eagle Oldsmobile replacement rods and have the crank ground for proper clearances, then internal balance it with an ATI balancer (or other quality unit) and some brand of SFI approved flexplate for internal balance.

Can anyone tell me the ins and outs of using the ATI balancer with stock pulleys, etc.; does everything line up fine, I just have to grind some extra clearance on the water pump and use a different pointer ?

Any guesses on what the extra .200 of stroke would be worth for power?

The cylinder heads are being flow tested and should be finished by Wednesday, as well as flow testing the Performance Products Hurricane EFI intake attached to the head ( I want to see how much it flows when bolted to the head, and we are going to have two ports tested to see how the lower ports flow).

Last edited by Battenrunner; June 23rd, 2018 at 07:41 PM.

#33

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Geez, derail much?

How about this for proof of crappy builders, even those who used to have a very good name, like Joe Mondello......

THANK GOD I decided to pull this engine down.

The amount of gasket shellac that was literally poured down into this engine is on the ridiculous side.... Every cylinder and every piston was literally coated with this crap, and it evan ran down into every ring pack and between every ring land. Also, to boot, we found that in place of the plug in the block that was supposed to oil the distributor gears, there was a solid plug installed with no oiling hole.......

Every Clevite 77 P series rod and main bearing had a couple of slight polished areas (likely from the dang clearances being way too tight), but the Forged 455 crank has only been turned .010/.010 so far.

There was trash in every oil galley, but I didn't see any in the assembled rotating components.

Between the crap on the rings and pistons being hard as a rock, and gumming up the rings and the cylinders and creating extreme drag, the oiling hole-less plug in the back of the block, and the way-too-tight bearings everywhere, this thing was guaranteed to be ruined shortly after starting up.

It does have ARIAS speedmaster pistons, which I took to the head shop today with the heads. We are going to have the heads milled and the guy is going to CC the chambers first to verify the compression ratio we have now. We did plate it and use the burette to verify the CC's of the piston while I was there, and it checks out at 23cc's of dish volume.

I am pretty sure we are going to send all the bearings off to have them Polydyne coated, and we are going to have the crank clearances for the bearings ground into it unless someone can really talk me into stroking this crank......... Apparently, the crank shop here is very good and very reputable and affordable.

So, I can offset-grind/stroke the Forged 455 steel crank by .200 more stroke to attain a stroke of 4.450, and I can use/modify a set of 6.635 eagle rods by narrowing the little end by .062 width, pressing in new eagle undersize wrist pin bushings, and have them honed to fit the Arias pin sizes of .980 (vs. .989-.990 of the factory BB Chevrolet size). I believe the pistons we have may clear the crank weights, but if not, the weights can be profiled by the crank shop as well.

Can someone verify if I would have to grind the block for rod bolt clearance if it was stroked?

Otherwise, if we don't stroke it, we will use the Eagle Oldsmobile replacement rods and have the crank ground for proper clearances, then internal balance it with an ATI balancer (or other quality unit) and some brand of SFI approved flexplate for internal balance.

Can anyone tell me the ins and outs of using the ATI balancer with stock pulleys, etc.; does everything line up fine, I just have to grind some extra clearance on the water pump and use a different pointer ?

Any guesses on what the extra .200 of stroke would be worth for power?

The cylinder heads are being flow tested and should be finished by Wednesday, as well as flow testing the Performance Products Hurricane EFI intake attached to the head ( I want to see how much it flows when bolted to the head, and we are going to have two ports tested to see how the lower ports flow).

How about this for proof of crappy builders, even those who used to have a very good name, like Joe Mondello......

THANK GOD I decided to pull this engine down.

The amount of gasket shellac that was literally poured down into this engine is on the ridiculous side.... Every cylinder and every piston was literally coated with this crap, and it evan ran down into every ring pack and between every ring land. Also, to boot, we found that in place of the plug in the block that was supposed to oil the distributor gears, there was a solid plug installed with no oiling hole.......

Every Clevite 77 P series rod and main bearing had a couple of slight polished areas (likely from the dang clearances being way too tight), but the Forged 455 crank has only been turned .010/.010 so far.

There was trash in every oil galley, but I didn't see any in the assembled rotating components.

Between the crap on the rings and pistons being hard as a rock, and gumming up the rings and the cylinders and creating extreme drag, the oiling hole-less plug in the back of the block, and the way-too-tight bearings everywhere, this thing was guaranteed to be ruined shortly after starting up.

It does have ARIAS speedmaster pistons, which I took to the head shop today with the heads. We are going to have the heads milled and the guy is going to CC the chambers first to verify the compression ratio we have now. We did plate it and use the burette to verify the CC's of the piston while I was there, and it checks out at 23cc's of dish volume.

I am pretty sure we are going to send all the bearings off to have them Polydyne coated, and we are going to have the crank clearances for the bearings ground into it unless someone can really talk me into stroking this crank......... Apparently, the crank shop here is very good and very reputable and affordable.

So, I can offset-grind/stroke the Forged 455 steel crank by .200 more stroke to attain a stroke of 4.450, and I can use/modify a set of 6.635 eagle rods by narrowing the little end by .062 width, pressing in new eagle undersize wrist pin bushings, and have them honed to fit the Arias pin sizes of .980 (vs. .989-.990 of the factory BB Chevrolet size). I believe the pistons we have may clear the crank weights, but if not, the weights can be profiled by the crank shop as well.

Can someone verify if I would have to grind the block for rod bolt clearance if it was stroked?

Otherwise, if we don't stroke it, we will use the Eagle Oldsmobile replacement rods and have the crank ground for proper clearances, then internal balance it with an ATI balancer (or other quality unit) and some brand of SFI approved flexplate for internal balance.

Can anyone tell me the ins and outs of using the ATI balancer with stock pulleys, etc.; does everything line up fine, I just have to grind some extra clearance on the water pump and use a different pointer ?

Any guesses on what the extra .200 of stroke would be worth for power?

The cylinder heads are being flow tested and should be finished by Wednesday, as well as flow testing the Performance Products Hurricane EFI intake attached to the head ( I want to see how much it flows when bolted to the head, and we are going to have two ports tested to see how the lower ports flow).

#34

Yeah, that is why I am leaning more on the side of just fixing the crank clearances....

The intake valves are Manley severe duty pro flow 11824's, which are 2.055 diameter. It has Manley severe duty 11805 Exhaust valves, which are 1.71 diameter.

We may go to a Canton oil pan also....

The intake valves are Manley severe duty pro flow 11824's, which are 2.055 diameter. It has Manley severe duty 11805 Exhaust valves, which are 1.71 diameter.

We may go to a Canton oil pan also....

#35

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

Yeah, that is why I am leaning more on the side of just fixing the crank clearances....

The intake valves are Manley severe duty pro flow 11824's, which are 2.055 diameter. It has Manley severe duty 11805 Exhaust valves, which are 1.71 diameter.

We may go to a Canton oil pan also....

The intake valves are Manley severe duty pro flow 11824's, which are 2.055 diameter. It has Manley severe duty 11805 Exhaust valves, which are 1.71 diameter.

We may go to a Canton oil pan also....

#36

Yeah, the intake size seemed small to me..... but, I want to see how they flow with the 2.055 valves. May be good enough to not worry about doing more. I think the intake will be the real choke point of the intake tract anyways...... so we are looking at selling the Professional Products setup to someone with a more stock setup and possibly going to an intake with more cross section (Holley Street dominator or Edelbrock Victor) to match the heads and modify it for injector bungs and rail mounts.

Are you talking about Mile High Crankshaft grinding? I spoke to his wife, and she was very nice, but she acted like it would be him doing it as it is sensitive work to sneak up on grinding extra bearing clearances or offset-ground stroking. I relayed how important this crankshaft is to us and how hard it is to obtain them in good shape, so she seemed to understand.

Since we are this far down with it, we are going to go Eagle rods to eliminate any worries with the rods. I may also spray this engine with some Nitrous in the future, or do some type of supercharger, so I don't want to be on the edge of the current weak component capabilities.

Are you talking about Mile High Crankshaft grinding? I spoke to his wife, and she was very nice, but she acted like it would be him doing it as it is sensitive work to sneak up on grinding extra bearing clearances or offset-ground stroking. I relayed how important this crankshaft is to us and how hard it is to obtain them in good shape, so she seemed to understand.

Since we are this far down with it, we are going to go Eagle rods to eliminate any worries with the rods. I may also spray this engine with some Nitrous in the future, or do some type of supercharger, so I don't want to be on the edge of the current weak component capabilities.

#37

#38

Registered User

Join Date: Aug 2012

Location: Colorado Springs Colorado/Thousand Oaks Ca

Posts: 1,719

This gets those pistons off safely............the question is, do you really want to save them?

#39

Yeah, I know they use super thick rings... but yes, I really hope we don't have to buy a $700 new set of pistons. We still have a lot more of the car to complete and I know they aren't the latest,lightest, most trick technology, but I don't think I would be giving up more than 15 hp versus a more modern piston design. I may look into the Total Seal Advantage ring sets..... to run the thinner rings on these pistons....

probably not worth the $150-$200 for another set of rings to make another 10hp

I will be checking all of these rings and filing them to fit the way I like them, with the 2nd ring having a wider gap the top ring....

probably not worth the $150-$200 for another set of rings to make another 10hp

I will be checking all of these rings and filing them to fit the way I like them, with the 2nd ring having a wider gap the top ring....

Last edited by Battenrunner; June 23rd, 2018 at 11:27 PM.

#40

Adding stroke wonít change the windage much if any on this setup. Youíre not adding counterweight, nor are you adding rod throw mass in the crank, youíre just moving the rod out a bit by the offset grind. And youíd be using a rod with a smaller big end, so thatís actually better. But thatís your call. And adding cubes will limit a head, but you donít even know the flow numbers yet so Iíd make that decision after you have all the facts.

But I would use the available 2.125 intake and have the bowls blended for it. If theyíre anything like the other aftermarket heads, theyíll be big enough already. Too bad it has the 1.71 ex though, donít need that, Iíve made over 600 with the 1.68, no problem.

And dont cut the counterweights. Internally balance it and youíll be fine. if anything send it to Moldex and theyíll lighten the rod throws etc., otherwise leave it alone.

Hope this helps.

But I would use the available 2.125 intake and have the bowls blended for it. If theyíre anything like the other aftermarket heads, theyíll be big enough already. Too bad it has the 1.71 ex though, donít need that, Iíve made over 600 with the 1.68, no problem.

And dont cut the counterweights. Internally balance it and youíll be fine. if anything send it to Moldex and theyíll lighten the rod throws etc., otherwise leave it alone.

Hope this helps.

Last edited by cutlassefi; June 24th, 2018 at 05:35 AM.