Oil restrictors?

#1

Oil restrictors?

So i have problems with my new engine wearing out bearings quite fast . First let me tell you about my old 455 that is rock solid.

Itís a later block , Fa, with a later crankshaft small cn, I donít know what the clearance is on the rod or mains, but whatever they are it works. It has a hv oil pump, I donít know what spring, but it is not shimmed, and has a 5 qt pan. The block has cam bearing restrictors with regular cam bearings, the cam is a JM 25 28 hydualic flat tappet. It has Joe Mondello restricted pushrods, Scorpion rockers. The heads are iron E heads with Ferra valves and no drainback mods. Torker intake with Holley 950. IíVe had this engine about four years and spanked it regularly, runs flawless. I shift it at 6500 ish all the time, thats right around where it stops pulling. Oil pressure is always 60 psi at high rpm. Also Clevite full groove mains.

The new 455 is built more for racing. Older F block with no cam bearing restrictors. Crank is a bigN one. That one is ground for large clearances, 4 thou. It has had Speed pro half grooved bearings and Clevite full groove bearings. Also a high volume oil pump with shimmed green spring, and a eight qt pan with correct 2Ē drop pickup. I have Eagle rodís with Icon flat top pistons. The cam is a Cam Motion solid roller with 609/254-586/258 on 108 LSA. Crower 66294h lifters and no lifter bore restrictors. 3/8 unrestricted pushrods. To top it off i have a Edelbrock heads with 57cc chambers, so it comes out to 12/5:1. Also a Torker and same 950. Also Jesel shaft rockers.

This engine gets about 15 minutes out of a set of rod bearings. I have never even really opened it up yet. The first time i had it together i was at a stoplight idleing in gear and watched the oil pressure drop off slowly and would not move when the engine was revved. Got it apart and it had shredded the rod bearings,mains not too bad. So I thought it was too tight, 3 on mains,2.5 on rods. Got the crank ground for 4 thou everywhere. Ran it for about 15 minutes at low rpm around 3000, got home cut the filter with snips, lots of copper and silver. It had great oil pressure and no mechanical noise. Got it apart and it was the rod bearings again. The machinist checked the rods before and so did i, they were good,the crank measures right on everywhere.

So i guess i almost have a magazine test article going on here. To restrict or not to restrict, that is the question.

Itís a later block , Fa, with a later crankshaft small cn, I donít know what the clearance is on the rod or mains, but whatever they are it works. It has a hv oil pump, I donít know what spring, but it is not shimmed, and has a 5 qt pan. The block has cam bearing restrictors with regular cam bearings, the cam is a JM 25 28 hydualic flat tappet. It has Joe Mondello restricted pushrods, Scorpion rockers. The heads are iron E heads with Ferra valves and no drainback mods. Torker intake with Holley 950. IíVe had this engine about four years and spanked it regularly, runs flawless. I shift it at 6500 ish all the time, thats right around where it stops pulling. Oil pressure is always 60 psi at high rpm. Also Clevite full groove mains.

The new 455 is built more for racing. Older F block with no cam bearing restrictors. Crank is a bigN one. That one is ground for large clearances, 4 thou. It has had Speed pro half grooved bearings and Clevite full groove bearings. Also a high volume oil pump with shimmed green spring, and a eight qt pan with correct 2Ē drop pickup. I have Eagle rodís with Icon flat top pistons. The cam is a Cam Motion solid roller with 609/254-586/258 on 108 LSA. Crower 66294h lifters and no lifter bore restrictors. 3/8 unrestricted pushrods. To top it off i have a Edelbrock heads with 57cc chambers, so it comes out to 12/5:1. Also a Torker and same 950. Also Jesel shaft rockers.

This engine gets about 15 minutes out of a set of rod bearings. I have never even really opened it up yet. The first time i had it together i was at a stoplight idleing in gear and watched the oil pressure drop off slowly and would not move when the engine was revved. Got it apart and it had shredded the rod bearings,mains not too bad. So I thought it was too tight, 3 on mains,2.5 on rods. Got the crank ground for 4 thou everywhere. Ran it for about 15 minutes at low rpm around 3000, got home cut the filter with snips, lots of copper and silver. It had great oil pressure and no mechanical noise. Got it apart and it was the rod bearings again. The machinist checked the rods before and so did i, they were good,the crank measures right on everywhere.

So i guess i almost have a magazine test article going on here. To restrict or not to restrict, that is the question.

#8

#14

Does the crankshaft have a fillet and the bearings are facing the correct way? They have an offset built in just for that reason.

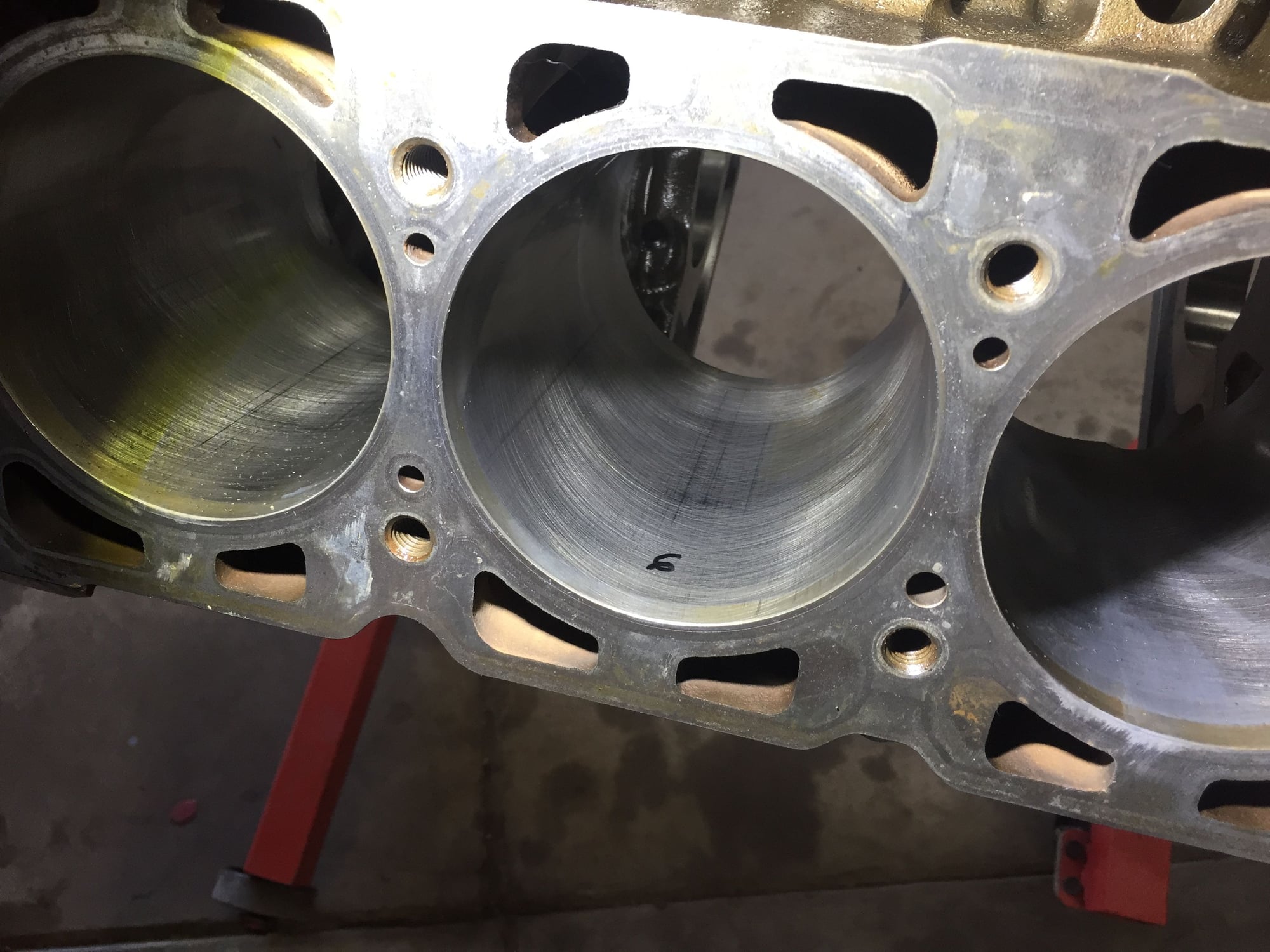

Clearly they are worn on one side more than the other. Is there taper on the rod journal from one side to the other? Lastly, what was the breakaway torque to get that short block assembly rotating?

Clearly they are worn on one side more than the other. Is there taper on the rod journal from one side to the other? Lastly, what was the breakaway torque to get that short block assembly rotating?

Last edited by TripDeuces; March 23rd, 2018 at 05:15 PM.

#15

You need to find another machinist, he sucks.

Just because things are in size doesnít mean Theyíre IN-LINE.

I see clear misalignment issues and most likely a poor relationship between the angle of the rods/pistons vs the cylinders, theyíre most likely not perpendicular. I believe your crank pins arenít parallel either.

You need to find a better machinist.

Just because things are in size doesnít mean Theyíre IN-LINE.

I see clear misalignment issues and most likely a poor relationship between the angle of the rods/pistons vs the cylinders, theyíre most likely not perpendicular. I believe your crank pins arenít parallel either.

You need to find a better machinist.

Last edited by cutlassefi; March 23rd, 2018 at 05:35 PM.

#17

Well, im not sure what are you asking ( might be me), but you could install rotating assembly with pistons on #1,2,7 & 8 cylinders. Then you can measure bank-to-bank difference between on zero-deck between those two farthest pistons for each other per bank.

#18

The only real way is to mount the block in a boring bar, then run a dual indicator down the bores.

Iíd start from scratch and have it align hone first, then measure the square from there.

#19

Okay, so i wasnt understanding what he was asking for, sorry for that.

#20

The block was line honed as part of the initial build. I found a different machine shop in town that has a cnc machine that registers on the main line and is able to probe the boreís to see if everything is in order. Definitely going to have it checked out before going any further

#21

#22

It looks like a definite taper on those bearings. My guesses:

1) Line hone not square to the cylinder bores (perpendicular) Depending on how this was set up and measured this could cause a bunch of problems. Bad or incorrect math, user error, boring machine tolerances excessive or bent. The piston wants to go straight up and down in the bore but the crank center line angle is not 90* to the bore or the bores aren't square to the crank or deck. Are there excessive wear marks on the piston skirts 90* to the thrust faces? Are the wrist pin bores and or the small end of the rod square. Were the rods reconditioned improperly and not square? This all makes my head spin.

2) Taper on the rod journal. I think this is less likely because measuring the bearing clearance would show a diff between the two rods on the same journal right off the bat. Of course that assumes if it was checked at all.

3) Oil contamination. Why it would be predominately on one side only doesn't fit

#1 is where I'm going

1) Line hone not square to the cylinder bores (perpendicular) Depending on how this was set up and measured this could cause a bunch of problems. Bad or incorrect math, user error, boring machine tolerances excessive or bent. The piston wants to go straight up and down in the bore but the crank center line angle is not 90* to the bore or the bores aren't square to the crank or deck. Are there excessive wear marks on the piston skirts 90* to the thrust faces? Are the wrist pin bores and or the small end of the rod square. Were the rods reconditioned improperly and not square? This all makes my head spin.

2) Taper on the rod journal. I think this is less likely because measuring the bearing clearance would show a diff between the two rods on the same journal right off the bat. Of course that assumes if it was checked at all.

3) Oil contamination. Why it would be predominately on one side only doesn't fit

#1 is where I'm going

#24

If the crank is "light" vs the correct bobweight it will beat the pins and rod journals. Early big block Mopars had this problem, they would beat the crap out of the wrist pins.

And once it starts to go the rest of whatever is downstream will too, and it doesn't take long.

#26

The pistons look fine as near as I can tell from the picture. Can you show one from the "side" of the piston where the most wear would be ? Are the wear marks straight up and down ?

Also a picture or two of the block where the main bearings sit.

Personally I think there might be a combination of issues. Oiling system ? Bearing clearances and how was the crankshaft ground.

Someone else mentioned this . . are the rods on the pistons the correct direction ? I am pretty sure that the bearing "tangs" should be facing in towards the camshaft.

Very hard to troubleshoot something like this without being there in person.

Also a picture or two of the block where the main bearings sit.

Personally I think there might be a combination of issues. Oiling system ? Bearing clearances and how was the crankshaft ground.

Someone else mentioned this . . are the rods on the pistons the correct direction ? I am pretty sure that the bearing "tangs" should be facing in towards the camshaft.

Very hard to troubleshoot something like this without being there in person.

#27

Yeah definitely hard to diagnose via the Internet. The pistons all look good, no wierd wear or anything like that. All the rods were installed with the chamfer facing the journal cheek. The crank is fine. If the block had cocked boreís the wear pattern on the bearings would be opposite of each other not concentrated on one side like i have. The thrust is really sealing the deal for lack of lube. I run the same turbo400 and cooler setup with the other engine and never had a problem. This crankís thrust surface is fine, no sunburst pattern, and very smooth. The only thing that could be causing it to wear as quickly as it does,is lack of oil. Itís going back together pretty soon, ill let you guys know how it turns out. Thank you all for your feedback.

#28

You should find the cause before you put it back together.

Give one of the Olds specific engine builds a call that have build a lot of these engines.

Rocket Racing

BTR Performance

See if they will be willing to help you out ??

Give one of the Olds specific engine builds a call that have build a lot of these engines.

Rocket Racing

BTR Performance

See if they will be willing to help you out ??

#29

What was the oil pressure like ?

4.39 of the video Bill explains main stud interference with the oil pump, that prevents proper seating to the rear main cap.

4.39 of the video Bill explains main stud interference with the oil pump, that prevents proper seating to the rear main cap.

Last edited by Bernhard; March 28th, 2018 at 06:43 AM.

#30

The oil pressure was good even with the big clearances, 70 cold 45 hot at about 2500 rpm and 25 idleing. I have the max perf olds book, read it cover to cover. It has alot of good info, thats why i had the crank ground for loose clearances the second time around. Iím aware of the oil pump interference with the main cap hardware. My pump is clearenced for it and sits flat on the cap. I have the block tapped for restrictors on the cam bearings and lifter bores . Been doing alot of reading about engines originally designed for hydraulic lifters and trunnion or skid ball rockers, and when the oems put solid lifters in those engines back in the muscle car days. They made the lifters very restrictive, because the block itself flows way more oil than needed. I donít have one stock component in my valve train, so why leave it stock especially if im wasting bearings at half hour intervals. The crank is getting polished, itíll be ready tomorrow,just have to clean the block. Iíll let you know how it goes. Thankís again

#31

Found this from Clevite which has a wealth of info.

http://www.wilmink.nl/Clevite/Clevit..._tech_info.pdf

http://www.wilmink.nl/Clevite/Clevit..._tech_info.pdf

#33

Well looks like restrictors worked for me, just got it back together last night. Thats the filter on the second oil change. Drove it around a bunch today, oil pressure is 60 cruising, 30 idleing in gear. Runs perfect no valvetrain noise. Wish i would have done it to begin with.

#37

Their is a very good Olds engine builder by the name of Milan who used to be a great source of information on ROP.

He did many oil modifications to his builds and his builds were very successful.

I can't remember if he used restrictors?

He did many oil modifications to his builds and his builds were very successful.

I can't remember if he used restrictors?

#38

I have a 60 over 455 that was reported to be done by Joe M. back in the day. Not sure if that is true or not. It was in a full size blazer when i bought it. It has restrictors. Ran great but the previous owner said it like to eat cam bearings. I also have replaced the cam twice in it. I pulled it and it has been sitting. I will fully disassemble it and have it line honed, and balanced. all rods sized checked and corrected if needed and I have a new crank for it. I am replacing the cam and lifters and the heads are going to be fully inspected and what ever needed done. I will not run restrictors in this engine. My main reason is I will not be running it at extreme RPM's it will be a street driving engine. It will be anally cleaned and the oil will be changed often and with great filters and oil. I just don't see a reason to run restrictors on a street engine.

Just my 2 cents

Larry

Just my 2 cents

Larry

Thread

Thread Starter

Forum

Replies

Last Post