Making good 3 piece performance pushrods into oil restricted ones

#1

Making good 3 piece performance pushrods into oil restricted ones

We have some nice, heavy duty pushrods that are the correct length, but they have .080 oiling holes top and bottom.... and we need restricted pushrods to keep the oil down more in the mains and lifters, and not up in the heads.... the goal was to get .035 to .040 oiling holes

ideas researched and decided against:

1. Pipe cleaners- yes, they work, but they will dump a bunch of fuzz through the oiling system and the wire will eventually come out and get broke off by the rocker arm and leave tiny metal wire pieces circulating in the oil.

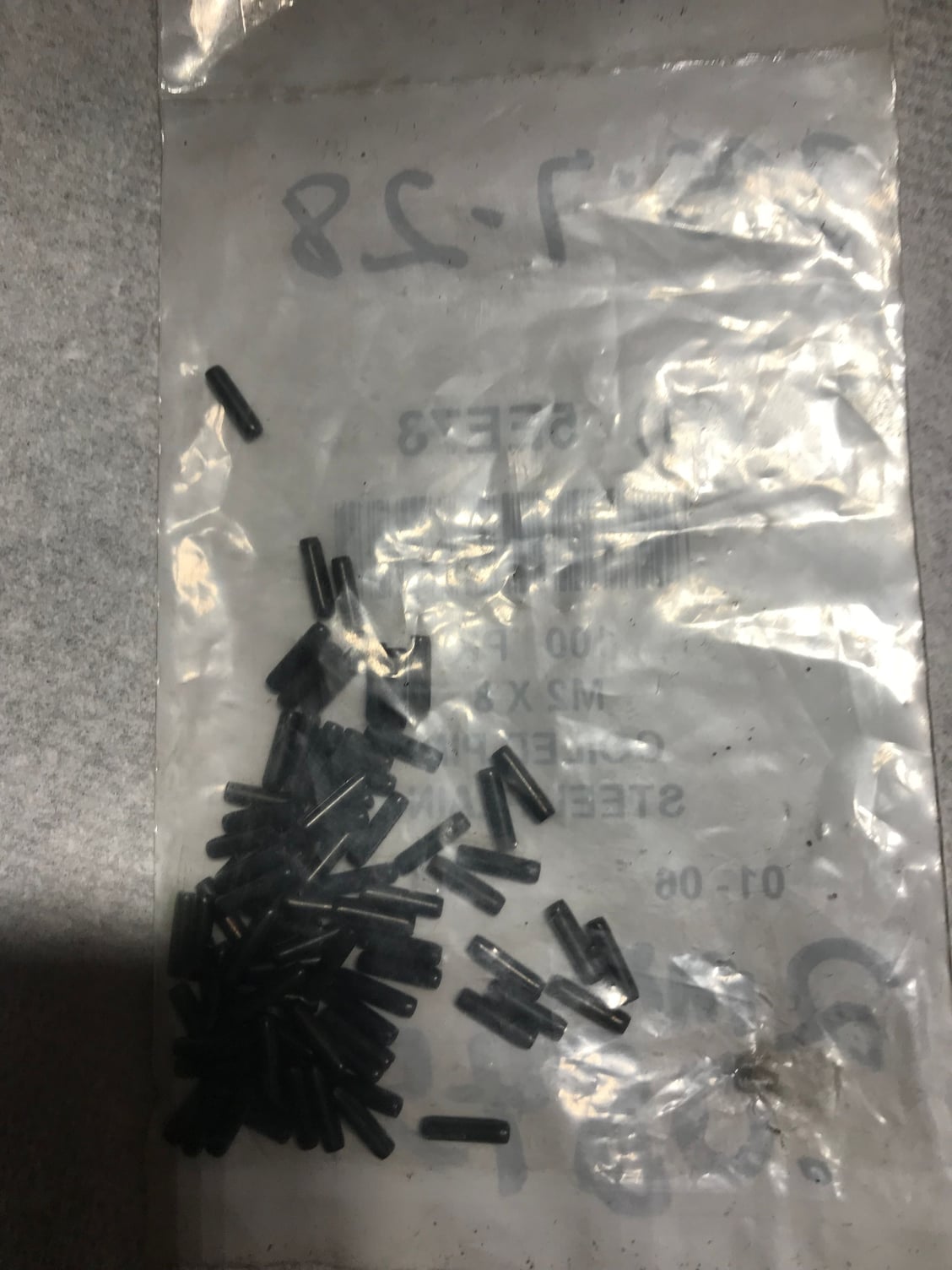

2. Roll pins- local hardware store had some that fit mediocre to crappy at best, not very thick roll pins and restricted hole size was still .055 diameter, and roll pins werenít tight enough to trust. Sizes were either too small or too big to be tight.

3. Have new ends installed in pushrods- could split or damage the pushrod when disassembling, would likely change the overall length, which is correct.

4. Buy new restricted pushrods for $200+

my solution:

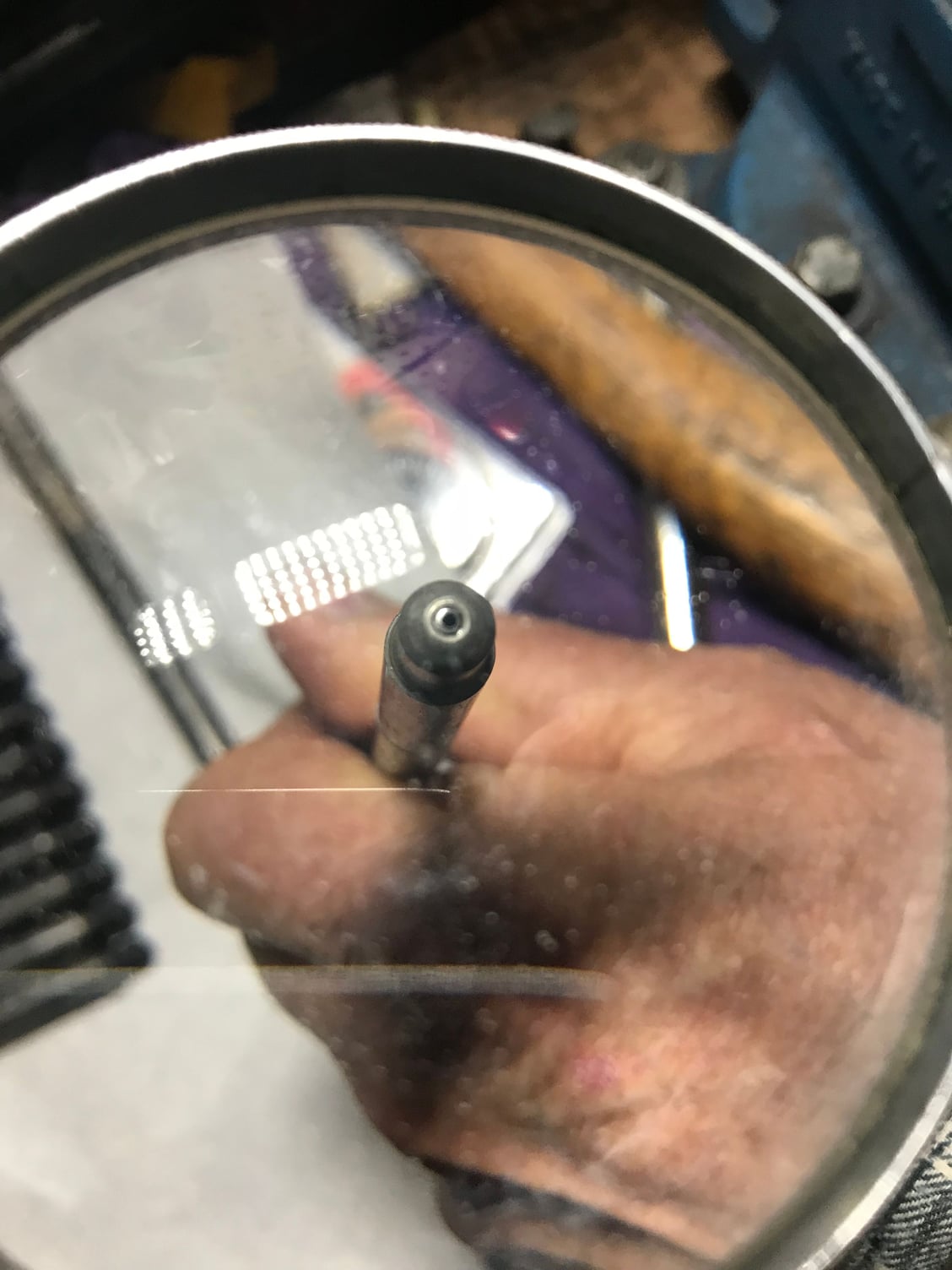

spring pins!

More specifically, 2mm diameter by 8mm length spring pins from Grainger.

These are much stronger than roll pins and they have a much higher tension as well with high quality steel. The other added benefit is they have the proper size hole when they are tapped into an .080 pushrod hole.

Once the spring pin restrictor is installed, it has a hole size of .0375-.038, according to pin gauges, so it is virtually a perfect restricted pushrod, which normally come with .040 holes.

I did not use loctite, as these were a very tight fit with decently aggressive taps from the hammer to slowly fit them in.

Please use at your discretion and skill level, ymmv, and I am not responsible if you mess up anything with this mod.

Last edited by Battenrunner; October 7th, 2018 at 11:22 PM.

#4

I did the same with roll pins. Just depends on your pushrod as the holes are always slightly different. I got the fancy Comp 3/8 pushrods and noted that the hole on the solid side is a different size than the hole on the installed side. And it's awfully hard stuff, so drilling it out didn't go well. One side had a very short restriction so it was easy to push the pin right past it and then have a rattle toy. I used a jewler's phillips to get the pin pushed a bit past the surface. Using a pin punch tended to cause the roll pin to collapse or fold, but the phillips had a bit more of a staking result.

Anyway, the point is for anyone looking to do this, you may need to mess around with roll/spring pin sizes a little to find something that fits well and figure out how your pushrods are constructed. Get spares.

Anyway, the point is for anyone looking to do this, you may need to mess around with roll/spring pin sizes a little to find something that fits well and figure out how your pushrods are constructed. Get spares.

#5

I would just buy restricted push rods. Not trying to be negative but with the cost of engine builds running in to $$$$ ,saving cents on home built restricted push rods does not add up.

If it was a junk yard build or a Mulligan build okay maybe then.

If it was a junk yard build or a Mulligan build okay maybe then.

Last edited by Bernhard; October 13th, 2018 at 07:50 AM.

#6

Is there any follow up on roll pinning pushrod. Trying to sort out motor 455 .

Thinking of trying this , sort out the motor if it run well, buy new pushrod

Thanks Frank

Thinking of trying this , sort out the motor if it run well, buy new pushrod

Thanks Frank

Last edited by Frank5s; August 28th, 2023 at 07:40 AM.

#7

I did that to a set of Comp Magnum (might've been Hi-Tech? but I think Magnum) pushrods. 8 of the pushrod ends cracked and split in half after a few hours of running. That was after I drilled out the ends so the roll pin had a light fit.

#10

If you are 100% sure you have too much oil going to the headsÖonly then should you limit the feed.

you need oil to cool the springs and take heat away from the head itself. Lube the rockers , cool the exhaust valve etc.

you need oil to cool the springs and take heat away from the head itself. Lube the rockers , cool the exhaust valve etc.

#11

#12

I've posted this before, but my 455 has a mix of pushrods in it, all the same length and style but different size restrictor tips. When Milan and I assembled it, we spun the oil pump on the stand and watched everything oil. You couldn't tell any difference in the apparent flow rate rocker to rocker. It wasn't the most scientific test, but our conclusion was the lifter metered the oil before the pushrod, and you weren't going to see a difference up top. I had it apart last year due to an intake gasket leak and didn't see any wear differences.

#13

I've posted this before, but my 455 has a mix of pushrods in it, all the same length and style but different size restrictor tips. When Milan and I assembled it, we spun the oil pump on the stand and watched everything oil. You couldn't tell any difference in the apparent flow rate rocker to rocker. It wasn't the most scientific test, but our conclusion was the lifter metered the oil before the pushrod, and you weren't going to see a difference up top. I had it apart last year due to an intake gasket leak and didn't see any wear differences.

Thread

Thread Starter

Forum

Replies

Last Post

boese1978

Major Builds & Projects

5

July 22nd, 2017 04:12 PM