Oldsmobile 307 Camshaft Thrust Plate

#1

Oldsmobile 307 Camshaft Thrust Plate

Hello fellow Olds nuts! Does anybody here possibly have a good used '86-'90 Olds VIN Y / 9 307 factory camshaft thrust plate in their collection of goodies? The original GM part number was 22527023. I used to order these in through the GM SPO in the years past, though it has now evaporated out of existence - I can't even find an accurate image of this lil rascal anywhere these days! Here is some further reading of my hunt for this part:

http://www.lateral-g.net/forums/showthread.php4?t=54348

If you happen to have one you could part with, do please let me know!

http://www.lateral-g.net/forums/showthread.php4?t=54348

If you happen to have one you could part with, do please let me know!

#3

I'm smiling from ear to ear here just to finally see one in an image! Like some rare animal that has been extinct for ages has all of a sudden been spotted... Now how do I get it to come off of this computer screen and into my hands - just hit print, right? LOL ?

Do please let me know if this is something you could part with. This is the one last remaining item holding up my 488 build!

I am also going to discuss patterning this part for reproduction with my machinists, as I feel all Olds builds with or without rollercam could benefit from this part for how perfectly it controls the camshaft end play. A totally overlooked FACTORY Olds "million dollar engineering" solution to cam walk. Simple as it gets to install with zero machining - makes all of the thrust buttons out there look silly. I'm in the brake business, but envision hitting up all of the Olds specialists out there to evaluate. I would like to see them all jump on it, whether I produce it for them or they reproduce it on their own - this part needs to brought back from extinction!

Add another little gem that has now also become UNOBTANIUM when I wasn't looking - this thing also needs to come back out of extinction too:

https://www.cantonracingproducts.com...ILTER-ADAPTER/

https://www.cantonracingproducts.com....php?id=22-588

Anybody have a time machine?

Do please let me know if this is something you could part with. This is the one last remaining item holding up my 488 build!

I am also going to discuss patterning this part for reproduction with my machinists, as I feel all Olds builds with or without rollercam could benefit from this part for how perfectly it controls the camshaft end play. A totally overlooked FACTORY Olds "million dollar engineering" solution to cam walk. Simple as it gets to install with zero machining - makes all of the thrust buttons out there look silly. I'm in the brake business, but envision hitting up all of the Olds specialists out there to evaluate. I would like to see them all jump on it, whether I produce it for them or they reproduce it on their own - this part needs to brought back from extinction!

Add another little gem that has now also become UNOBTANIUM when I wasn't looking - this thing also needs to come back out of extinction too:

https://www.cantonracingproducts.com...ILTER-ADAPTER/

https://www.cantonracingproducts.com....php?id=22-588

Anybody have a time machine?

Last edited by Clark455; February 3rd, 2017 at 07:17 PM.

#4

another little gem that has now also become UNOBTANIUM when I wasn't looking - this thing also needs to come back out of extinction too:

https://www.cantonracingproducts.com...ILTER-ADAPTER/

https://www.cantonracingproducts.com....php?id=22-588........

https://www.cantonracingproducts.com...ILTER-ADAPTER/

https://www.cantonracingproducts.com....php?id=22-588........

#6

My long standing search for these extinct parts IS getting closer, in that I have at least finally found someone that actually has them. Now I just have to sweet talk Bob into letting them go to a new good home. Or? Borrow them so that I can pattern some reproductions!

#7

T6 Billet Oil Filter Remote Adapter Installed - plumbed to twin non bypass filters / oil cooler = 10 QT oil change (!)

Remote oil adapter installed on the last beast from years ago:

https://www.youtube.com/watch?v=W5lNicZS-L4

https://www.youtube.com/watch?v=daaTT2Igrus

Which also ran the factory Olds 307 cam thrust plate with the Crane conversion roller cam / lifter package.

#9

#10

#12

Hi Bob, excellent to hear that you did indeed find a second one of these plates on hand. It's always that way, in that I can't locate one anywhere and then it turns out you have two on hand that you had never even thought about!

As far as gauging interest for a production run of these, I have learned that this is a long slow road. First, itís awareness - 99% of the Olds guys have no idea this thing even exists, so a detailed post in front of everybody to explain it will need to be generated. Second, soak time will be needed (for it to sink in as to why they want it). Third, a general price point will have to be determined, speculating anything more than a $100 would have it stay in its current state of extinction.

Would you consider simply selling me the thrust plate and the oil adapter plate outright? I am trying to just score some parts to keep my build in a state of progress, hopefully running this April. Or? We make an arrangement where you send me the parts and I return them back to you in 30 days? I would be more than happy to document everything with some really good pictures and tech details.

Worth a good chuckle Ė while Iím sitting here writing this, it is like a 1000 watt halogen bulb just went off over my head (!) It just actually occurred to me that I have one of these thrust plates sitting here right in front of me, though it is inside of the phenomenally fantastic running H/O 307 currently installed in my í86 442 (that I just posted a picture of on the forum the other day). This the strongest running 307 I have ever seen Ė could easily convince passengers that it is a 350 rocket the way it performs (I have custom tuned the carb, burned a custom chip for it, removed some smog junk, but thatís it). It builds good power well past 5500 RPM! For some reason, I was positive that it was the earlier flat tappet H/O engine with the 5A heads. I went over and popped the hood and BAM, verified it IS indeed the later roller motor (7 heads and A4 intake). At least there is one more option now sitting here right under my nose the whole time, though I really donít want to have to tear into this virgin to dig this part out, just to pattern the part and then re-assemble it. I could also produce a detailed mechanical drawing of the oil filter relocation plate for the machinists to run with. That being said, it would be a whole helluva lot smoother sail to hand my machinists two live parts though!

So further to the discussion, no matter how I get my hands on a roller thrust plate and an oil filter relocation plate, I am definitely going to have my machinists reproduce at very least one or two master copies of each to place on my personal shelf. That is unless somebody else with more time on their hands decides to run these parts, which would save me the hassle! I have my hands so full with Hydratech that I really donít need to be getting into the production of other non related partsÖ

Only God knows if I will build anymore engines in my life time Ė I sure hope to! My last one was a whopping 15 years ago, and my current health issues Iím suffering with have me wondering if this may also possibly be my last. (Diabetes / high blood pressure has turned my life completely upside down over the last year Ė I am but a mere shadow of my previous self these days). BUT, if I do, itís most likely going to be another Olds and will smile having these two extinct parts ready to go the next time around ~

~

As far as gauging interest for a production run of these, I have learned that this is a long slow road. First, itís awareness - 99% of the Olds guys have no idea this thing even exists, so a detailed post in front of everybody to explain it will need to be generated. Second, soak time will be needed (for it to sink in as to why they want it). Third, a general price point will have to be determined, speculating anything more than a $100 would have it stay in its current state of extinction.

Would you consider simply selling me the thrust plate and the oil adapter plate outright? I am trying to just score some parts to keep my build in a state of progress, hopefully running this April. Or? We make an arrangement where you send me the parts and I return them back to you in 30 days? I would be more than happy to document everything with some really good pictures and tech details.

Worth a good chuckle Ė while Iím sitting here writing this, it is like a 1000 watt halogen bulb just went off over my head (!) It just actually occurred to me that I have one of these thrust plates sitting here right in front of me, though it is inside of the phenomenally fantastic running H/O 307 currently installed in my í86 442 (that I just posted a picture of on the forum the other day). This the strongest running 307 I have ever seen Ė could easily convince passengers that it is a 350 rocket the way it performs (I have custom tuned the carb, burned a custom chip for it, removed some smog junk, but thatís it). It builds good power well past 5500 RPM! For some reason, I was positive that it was the earlier flat tappet H/O engine with the 5A heads. I went over and popped the hood and BAM, verified it IS indeed the later roller motor (7 heads and A4 intake). At least there is one more option now sitting here right under my nose the whole time, though I really donít want to have to tear into this virgin to dig this part out, just to pattern the part and then re-assemble it. I could also produce a detailed mechanical drawing of the oil filter relocation plate for the machinists to run with. That being said, it would be a whole helluva lot smoother sail to hand my machinists two live parts though!

So further to the discussion, no matter how I get my hands on a roller thrust plate and an oil filter relocation plate, I am definitely going to have my machinists reproduce at very least one or two master copies of each to place on my personal shelf. That is unless somebody else with more time on their hands decides to run these parts, which would save me the hassle! I have my hands so full with Hydratech that I really donít need to be getting into the production of other non related partsÖ

Only God knows if I will build anymore engines in my life time Ė I sure hope to! My last one was a whopping 15 years ago, and my current health issues Iím suffering with have me wondering if this may also possibly be my last. (Diabetes / high blood pressure has turned my life completely upside down over the last year Ė I am but a mere shadow of my previous self these days). BUT, if I do, itís most likely going to be another Olds and will smile having these two extinct parts ready to go the next time around

~

~

#13

"Or? We make an arrangement where you send me the parts and I return them back to you in 30 days?"

My machinist has a modeling app (CAD/CAM) and could conceivably produce prints for your guy to work from, if that would work for you. Let me know.

My machinist has a modeling app (CAD/CAM) and could conceivably produce prints for your guy to work from, if that would work for you. Let me know.

#14

One missed dimension...

One thing I have learned over the years is that all it takes is one parameter to be off / not documented to render a part useless. I have plenty of fancy billet items here that are nothing but good looking paper weights from R & D sessions over the last 17 years of working with CAD / CAM produced items. The programming is only as good as the person doing the computer modeling, which all starts with good ol' fashioned live part measurements. Miss one measurement and you have yet another fancy paper weight - DOH! One wrong parameter and I possibly lunch an engine! Even something as simple as a beveled edge angle being off... My machinists have a very high tech optical comparator that can scan parts to within ten thousandths of an inch. Even with that super fancy tech, you still can't trust it 100% until you go over every last little detail manually to be exactly dead nuts.

I am not saying your machinist wouldn't absolutely dead nuts nail it, but I'd rather shoulder the burden of the process resulting in one old original live part placed next to the new reproduction prototype, and then measuring every last little parameter afterwards to be certain of exacting perfection beyond any shadow of any doubt. The other factor here is the metallurgy - I want to run the original part through the Rockwell test stand to measure its hardness. With a billet steel roller cam, I'd hate to see a wear issue created by making an incorrect choice of material to be used. The engine block face is of course the factory (high nickel content) Olds spec cast iron, though I seem to recall the last brand new genuine GM Olds 307 thrust plate I held in my hands (years ago!) may have been a melanized type of material - I could be wrong, as it has been years...

Summary? I would not be pleased with the replacement part(s) until I could literally hold both the old part and the new part in my hands for intense initial scrutiny. Then, a live test fit of the old original part to measure cam thrust end play, followed by a test fit of the new replacement part = the only way I'd assemble the engine and run it. I'm actually not all that concerned about the intense accuracy of the oil filter relocation plate adapter, but the cam thrust plate needs to be perfection! As such, I would like to have you consider at least sending me one of the OE Olds 307 cam plates, either sold outright, or arranged to return unmolested as soon as the process is complete. I am hating the thought of digging the thrust plate out of my own 307 to do this (or buy an entire 307 core from a local bone yard) when you have dug two of these up on your end!

I am not saying your machinist wouldn't absolutely dead nuts nail it, but I'd rather shoulder the burden of the process resulting in one old original live part placed next to the new reproduction prototype, and then measuring every last little parameter afterwards to be certain of exacting perfection beyond any shadow of any doubt. The other factor here is the metallurgy - I want to run the original part through the Rockwell test stand to measure its hardness. With a billet steel roller cam, I'd hate to see a wear issue created by making an incorrect choice of material to be used. The engine block face is of course the factory (high nickel content) Olds spec cast iron, though I seem to recall the last brand new genuine GM Olds 307 thrust plate I held in my hands (years ago!) may have been a melanized type of material - I could be wrong, as it has been years...

Summary? I would not be pleased with the replacement part(s) until I could literally hold both the old part and the new part in my hands for intense initial scrutiny. Then, a live test fit of the old original part to measure cam thrust end play, followed by a test fit of the new replacement part = the only way I'd assemble the engine and run it. I'm actually not all that concerned about the intense accuracy of the oil filter relocation plate adapter, but the cam thrust plate needs to be perfection! As such, I would like to have you consider at least sending me one of the OE Olds 307 cam plates, either sold outright, or arranged to return unmolested as soon as the process is complete. I am hating the thought of digging the thrust plate out of my own 307 to do this (or buy an entire 307 core from a local bone yard) when you have dug two of these up on your end!

#15

Or?

If you plan on reproducing these items, that's great! Heck, you may even make a profit producing these items if you get enough Olds specialists / enthusiasts interested. Full circle in the conversation, all I wanted was to source a new GM thrust plate and one of the Canton oil filer relocation plates anyway. Seeing that the items are discontinued made me pursue this whole discussion of bringing them back to life again. If your machinist can whip up a highly accurate replacement thrust plate of the correct metalurgy, and also a replacement oil filter relocation plate, then great! Let me be your first customer, and I will evaluate and then also buy a few extras. I don't exactly relish the thought of having my machinists go through all of the hassles and expenses to pattern these parts for only my build - to much of a dead end for the process involvement. The largest problem for me is tick tock, tick tock - I don't want this spooling off into holding up my build all too much longer, while balancing my needs to "nail it just right".

If you want to reproduce these items, then I won't bother going through the design process. By contrast, if you decide not to produce these items, I will pattern them. If I go through the process to pattern and test them, it would bother me as too much of a dead end for the investment to only produce two parts, which would then make me want to contact the Olds specialists out there to market them. Then they get knocked off by the rest of the aftermarket as seems to always be the case... (like CPP did with a few of my Hydratech designs)

Hell, I realize that I must be WAY overthinking this already. Hello, my name is Paul, and I am addicted to Oldsmobiles

Don't I wish it was as easy as building a Chevy:

https://www.summitracing.com/parts/c...make/chevrolet

https://www.summitracing.com/parts/s...make/chevrolet

Heck, even a F*rd - $6 damn measly dollars!!!

https://www.summitracing.com/parts/m...rd?prefilter=1

Being an OE production part at one time, I do NOT understand why Melling, Pioneer, or anybody else does not have this simple little part available - WTF, right?

At any rate...

If you want to reproduce these items, then I won't bother going through the design process. By contrast, if you decide not to produce these items, I will pattern them. If I go through the process to pattern and test them, it would bother me as too much of a dead end for the investment to only produce two parts, which would then make me want to contact the Olds specialists out there to market them. Then they get knocked off by the rest of the aftermarket as seems to always be the case... (like CPP did with a few of my Hydratech designs)

Hell, I realize that I must be WAY overthinking this already. Hello, my name is Paul, and I am addicted to Oldsmobiles

Don't I wish it was as easy as building a Chevy:

https://www.summitracing.com/parts/c...make/chevrolet

https://www.summitracing.com/parts/s...make/chevrolet

Heck, even a F*rd - $6 damn measly dollars!!!

https://www.summitracing.com/parts/m...rd?prefilter=1

Being an OE production part at one time, I do NOT understand why Melling, Pioneer, or anybody else does not have this simple little part available - WTF, right?

At any rate...

Last edited by Clark455; February 2nd, 2017 at 12:51 PM.

#16

Since we are on this subject, can any of you guys find a picture of the lifter valley area of a roller cam 307 or maybe tell me exactly what is different from the non roller engines ? I am rebuilding the 307 out of my Wifes Riviera and plan on using a hydraulic roller instead of the flat tappet cam. I can use the retrofit type lifters but would love to use the stock type instead if possible. I see the thrust plate setup, that is definitely the way to go if I can find one. Looks like they are pretty rare. I am going to do some measuring in the morning to see if maybe the setup out of the late model Chevy Small Blocks might be made to work.

#17

Incompatible...

Hi Bill - the '85-'90 Olds with factory roller cam ran a hydraulic lifter diameter of .921" versus the flat tappet engines that ran the .842" sized lifters. Unless you machine the lifter bores upsize, there is no way to run the factory roller lifters. Stay tuned on the camshaft thrust plate, as I am going to have a few of these machined back into existence!

#18

Hi Bill - the '85-'90 Olds with factory roller cam ran a hydraulic lifter diameter of .921" versus the flat tappet engines that ran the .842" sized lifters. Unless you machine the lifter bores upsize, there is no way to run the factory roller lifters. Stay tuned on the camshaft thrust plate, as I am going to have a few of these machined back into existence!

Aaahhh...... didn't realize that. Guess I will have to go with the retrofit lifters. A bit more pricy but no big deal.

#19

Hi Bill - the '85-'90 Olds with factory roller cam ran a hydraulic lifter diameter of .921" versus the flat tappet engines that ran the .842" sized lifters. Unless you machine the lifter bores upsize, there is no way to run the factory roller lifters. Stay tuned on the camshaft thrust plate, as I am going to have a few of these machined back into existence!

From the pic that Bob posted, it appears as thou the thrust plate is thin material and would need to be stamped and not CNC'd. Just my observation from the picture. I don't see a side view but???

Eric

#20

If its the small plate with the reamed hole and appears to be a split dowel pin, then that could be made easily out of stainless in any grade you choose in a machine shop with a good old school lathe and mill or CNC lathe with live tooling'

Eric

Last edited by 76olds; February 19th, 2017 at 08:07 AM.

#22

Thanks Randy,

I learned something with this thread. Drawing in Cad would be easy, Cam programming/ machining that thickness from a 1/8 plate not so much haha. I still wouldn't want to produce them in quantity on a CNC at that thickness. You would have to either waterjet/laser cut the outer/inner profile and bolt holes, then fixture to CNC mill the chamfer and step.

You could make it out of 01 PLATE, oil harden then grind if strength and flatness is needed. However some of the new dual phase stamping material in the thickness needed,, laser or waterjet then clamp, machine would be the way to go for a 1-2 off IMO.

Eric

I learned something with this thread. Drawing in Cad would be easy, Cam programming/ machining that thickness from a 1/8 plate not so much haha. I still wouldn't want to produce them in quantity on a CNC at that thickness. You would have to either waterjet/laser cut the outer/inner profile and bolt holes, then fixture to CNC mill the chamfer and step.

You could make it out of 01 PLATE, oil harden then grind if strength and flatness is needed. However some of the new dual phase stamping material in the thickness needed,, laser or waterjet then clamp, machine would be the way to go for a 1-2 off IMO.

Eric

#23

Thanks to ROCKETMAN269V

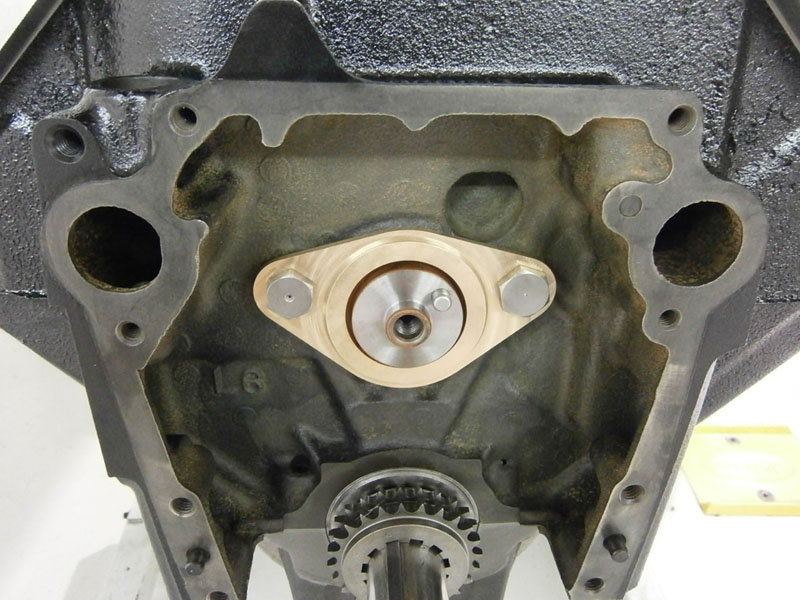

Many thanks to Bob for digging up this thrust plate and loaning it to me for patterning! Here it is test fit onto the 488 stroker, producing a cam thrust end play of .016"

#24

Thicker and bit more intricate than it looks

This plate didn't look that thick when it was pictured still installed onto Bob's 307 core, as it was carpeted with a layer of slime. It is a 1/4" thick, with a back cut of .080" ~ The stock non roller oil gallery plugs seat the plate just fine, so we don't have to go through the trouble of reproducing the slightly longer OE 307 gallery plugs to accompany the thrust plate installation (sigh of relief from me on that).

#25

Btw / fyi

The end game here of course is to yank the H/O 307 out of my 442 to then install this 488 stroker in its place - a jump from 5.0 to 8.0 liters should do the trick, 181 more cubes, right?

Soooo.... If anybody is interested in truly the best damn running 307 I have ever witnessed, this original 68,000 mile gem is up for sale. It is the '86 high output "roller motor" VIN 9 with the hotter cam (can surprisingly hear just a little bit of "cackle" out of the hotter factory roller cam here and there). It is so virgin that I haven't even done the valve cover gaskets on it yet, so they leak as expected - other than that, this thing is perfect. I have thoughts of keeping the "all original numbers matching engine" with the car, but not so much that I want to sit it off in the corner of the shop on an engine stand for the rest of its life (as I can't imagine somebody yanking the 488 out to place the 307 back in at any point in the future). I am looking for $1000, because of how simply perfect this thing is, combined with how remarkably strong this little rascal runs. To bad you are not in the area Bill, as this thing would just need a quick few gaskets while out before it found its way under your wife's Riviera hood (oil pan swap is all you would need to do for the FWD). I sure would like to have some interest manifest itself before I yank the engine out so that a buyer could experience the engine while still in the car (drive it). It seems like it is always suspect once yanked out as you can't really experience it after it is pulled. I will shoot some videos of it running through its paces if I can't find somebody to check it out personally before it is out of the car...

Soooo.... If anybody is interested in truly the best damn running 307 I have ever witnessed, this original 68,000 mile gem is up for sale. It is the '86 high output "roller motor" VIN 9 with the hotter cam (can surprisingly hear just a little bit of "cackle" out of the hotter factory roller cam here and there). It is so virgin that I haven't even done the valve cover gaskets on it yet, so they leak as expected - other than that, this thing is perfect. I have thoughts of keeping the "all original numbers matching engine" with the car, but not so much that I want to sit it off in the corner of the shop on an engine stand for the rest of its life (as I can't imagine somebody yanking the 488 out to place the 307 back in at any point in the future). I am looking for $1000, because of how simply perfect this thing is, combined with how remarkably strong this little rascal runs. To bad you are not in the area Bill, as this thing would just need a quick few gaskets while out before it found its way under your wife's Riviera hood (oil pan swap is all you would need to do for the FWD). I sure would like to have some interest manifest itself before I yank the engine out so that a buyer could experience the engine while still in the car (drive it). It seems like it is always suspect once yanked out as you can't really experience it after it is pulled. I will shoot some videos of it running through its paces if I can't find somebody to check it out personally before it is out of the car...

#26

You could draw it up in Cad and CNC it in two set-ups fixtured. It can be done without to much effort, of course depending on intricate tollerances as mentioned, material being used, flatness and if any heat treating is needed. Then.. well... ANUF-SAID.

Last edited by 76olds; February 20th, 2017 at 06:04 PM.

#28

Harmonics...

The way I understand it, this spring loaded thrust button was used to dampen certain harmonics at idle / off idle speeds. It seemed like there were quite a few GM applications that used this little spring loaded thrust button package for a few years, along with spring loaded timing chain tensioners - almost like a fad that came and left with the '80's. I have used it on and off in my builds, finding the thrust plate to be so good at what it does that this little thrust button seems a little superfluous. Interestingly, this item is still plenty available through various sources.

#29

Am I also correct in saying that the roller cam has a separate part in the front (shown in your picture) that keeps the cam from moving back into the block ? If that is the case I guess I need to find all of the pieces for the front.

I have a friend who has a complete roller 307 that I can have but it is still in the car and 300 miles away

I am going to call him tomorrow and see if I can talk him into pulling it apart for me.

I am going to call him tomorrow and see if I can talk him into pulling it apart for me.

#30

Poor cam core material

Yes, I am disqualifying everything I am saying "as to the best of my knowledge"... I knew everything when I was a young man, though the older I get, the more I realize that I only know what I *think* I know - right?

Having said that, it is my understanding that the factory '85-'90 Olds 307 "roller motor" cams were of a poor quality ductile iron instead of the (proper) tough austempered steel that they should have been. The supposed reasoning behind this was distributor drive gear compatibility. The $$$ high quality replacement Crane roller cams that I use have a separate cast iron rear section pressed onto the rear of the cam providing compatibility with standard distributor drive gears (saving installers from the hassle of running a bronze replacement distributor drive gear) (that wears out MUCH faster). Olds decided to place the higher quality steel round thrust wear flange onto the front of the camshaft as a separate item instead of doing the entire cam in the high class material (some dag blasted GM bean counter somewhere apparently intervened). Why you don't hear me talking about this separate piece is because the aftermarket billet steel conversion roller cams come with the standard Olds front cam flange already built into the cam as part of the item (not requiring this separate possibly even rarer factory Olds part). In speaking with various Olds specialists about this cam thrust plate, I have been told (though cannot confirm) that certain aftermarket dead stock replacement factory '86-'90 Olds 307 roller cams now ship in higher quality material (though not quite the austempered steel cores), precluding the need to transfer this steel cam thrust flange onto a new OE Olds 307 replacement cam...

(Crane 809611 pictured above)(with the stock classic Olds standard cam flange)

Last edited by Clark455; April 1st, 2022 at 03:37 PM.

#31

Soooo Bill... You don't know this, but there was a time were I was really big into the '79-'85 Buick Rivera's years ago. Why? My dad was chief of styling for Buick back in those days, and we were all riding around in "Turbo T's" back then (fun stuff to see your Dad's hand writing on the fenders) (the Riviera script). The little green / amber / red boost lights on the dash were always fun to watch LOL. I did things to the '79-'85 Riv's that people couldn't believe, such as mega turbo 3.8 / 4.1 builds, and even 455 dual quad builds (cutting the firewalls up to accommodate THM425 trannies and such). Everybody was doing rear wheel drive stuff, and it was just too much fun to be able to smoke the FRONT tires right past them watching their faces in disbelief. Aside from the '86 Vette wheels and tires that fit PERFECTLY (as part of a discovery when a previous employee attempted to play a joke on me years ago) and a disturbingly different exhaust note, nobody knew what kind off whoopass they were in for until it was way too late with those previous E body builds. Hiding a 455 dual quad Olds under an E body hood wasn't easy, but I couldn't stand the thought of any kind of hood modifications to a Riv

My advice? Forget about the 307. Find a 403 to freshen up instead. It will bolt right in with only an oil pan swap (need the E body pan to clear the driveline). It will provide excellent fuel economy because it won't have to struggle at all, run nice and smooth because you can underbuild it and still make gobs of torque, and won't look any different than the 307 when bolted in. It will even run well if you chose to put some / all of the factory smog garbage back on it too (comp controls handled the 96 cube increase like it was nothing if a factory smooth idle with good vacuum was available). The THM325 trans handled the torque monster 455 builds decently until hooked real hard, though never a problem with the 350 / 403 engines, so I can personally certify the FWD drivelines were good for about 350 horse. A good Olds 403 core has become so hard to find these days that I fear I may be sending you down a rabbit hole on that too, though I have one of those also sitting here on an engine stand in good running condition ready to go also if needed

5.0 or 6.6 liter? 96 more cubes? No brainer for me

TECH: The Olds 403 cannot use the cam thrust plate we have been talking about due to revised oil gallery locations as compared to all of the other production Olds engines. I could likely design a 403 only cam thrust plate, but that will have to come to pass once the current thrust plate project is completed (opening up the CAD plot and editing oil gallery plug mounting locations to accommodate the 403 will be the likely evolution of this current scenario unless I see zero demand)...

My advice? Forget about the 307. Find a 403 to freshen up instead. It will bolt right in with only an oil pan swap (need the E body pan to clear the driveline). It will provide excellent fuel economy because it won't have to struggle at all, run nice and smooth because you can underbuild it and still make gobs of torque, and won't look any different than the 307 when bolted in. It will even run well if you chose to put some / all of the factory smog garbage back on it too (comp controls handled the 96 cube increase like it was nothing if a factory smooth idle with good vacuum was available). The THM325 trans handled the torque monster 455 builds decently until hooked real hard, though never a problem with the 350 / 403 engines, so I can personally certify the FWD drivelines were good for about 350 horse. A good Olds 403 core has become so hard to find these days that I fear I may be sending you down a rabbit hole on that too, though I have one of those also sitting here on an engine stand in good running condition ready to go also if needed

5.0 or 6.6 liter? 96 more cubes? No brainer for me

TECH: The Olds 403 cannot use the cam thrust plate we have been talking about due to revised oil gallery locations as compared to all of the other production Olds engines. I could likely design a 403 only cam thrust plate, but that will have to come to pass once the current thrust plate project is completed (opening up the CAD plot and editing oil gallery plug mounting locations to accommodate the 403 will be the likely evolution of this current scenario unless I see zero demand)...

#32

That was my original plan when the car was still running. I was going to get a 350 and do it but ......... since it died and it is my Wife's "baby" and her daily driver, I need to get it done pronto. I am so swamped with work at the shop that I don't hardly have time to breathe so the 307 is going to stay in there. Its sitting on the boring machine as we speak

All I have to do is freshen the heads up, get some parts, balance the crank and put her back together. I hope Cranes lead time isn't too long on the cam. Now is a bad time with racing season starting soon.

All I have to do is freshen the heads up, get some parts, balance the crank and put her back together. I hope Cranes lead time isn't too long on the cam. Now is a bad time with racing season starting soon. We have hot rods in the family too so that is not an issue. She is driving our Tahoe in the meanwhile.

As far as cams go I was going to use a Crane one. Good to know that it already has the thrust flange on it

What's interesting about the factory roller cam is that it is actually a little bit "smaller" than the flat tappet cam ?

What's interesting about the factory roller cam is that it is actually a little bit "smaller" than the flat tappet cam ? One thing I did think about doing is changing the final drive to a steeper gear but I have not had time to even see what is in it now or what is even available now days. That should also give it a little more off the line oomph

Thanks for all your advice. I have done a ton of engines over the years but very few Oldmobiles.

#33

Further to the conversation...

Crane's lead time on my Olds conversion roller was about three weeks, so I suggest you give them a call right away to discuss what you are doing and see what they can do for you. Comparing flat tappet cam specs to roller cam specs is totally different, as the roller cams can come in with a tighter / smaller seat to seat and .050 duration *BUT* the roller opens the valves a helluva faster / further at low / mid lift ranges per its completely different cam lobe profile. A 260 advertised duration hydraulic flat tappet versus a 260 duration roller will be a different run time experience as a result. Before this spools off into a cam discussion, let me just say that you would do best to call your cam company and carefully discuss what you are doing and what you expect so that they can plug it all into their sophisticated softwares. Tell them you need a smooth idle with strong vacuum if you plan on retaining the factory engine control electronics, keep the valve lift mellow (as the roller will provide "more area under the curve", meaning you don't need high lifts because the valves will stay open in the "good flow range" much more as compared to the flat tappet actions).

THM325-4L Final drive ratios (same as rear end gear ratios) were mostly in the 2.78:1 range from what I recall. The Turbo Riviera had the 3.36:1 final drive, but you will pay hell combing the earth to try to locate one. If you do manage to find one somewhere, make sure you also score the speedo drive housing and output gear to go along with the revised gear ratio. I am not aware of anything being available as far as replacement ring and pinion gears for these. Since you have a TCC (lockup torque convertor), you could install a looser convertor (higher stall) while you have the engine out, knowing that you won't be heating the trans up excessively due to the TCC actuating. The 200R4 trans shares the same convertor design as your 325-4L, so you could upgrade from your 1600 +/- factory stall (tight) convertor to a nice 2000 +/- convertor very simply (source a '84 Turbo T rear wheel drive / Monte SS / Olds 442 convertor).

THM325-4L Final drive ratios (same as rear end gear ratios) were mostly in the 2.78:1 range from what I recall. The Turbo Riviera had the 3.36:1 final drive, but you will pay hell combing the earth to try to locate one. If you do manage to find one somewhere, make sure you also score the speedo drive housing and output gear to go along with the revised gear ratio. I am not aware of anything being available as far as replacement ring and pinion gears for these. Since you have a TCC (lockup torque convertor), you could install a looser convertor (higher stall) while you have the engine out, knowing that you won't be heating the trans up excessively due to the TCC actuating. The 200R4 trans shares the same convertor design as your 325-4L, so you could upgrade from your 1600 +/- factory stall (tight) convertor to a nice 2000 +/- convertor very simply (source a '84 Turbo T rear wheel drive / Monte SS / Olds 442 convertor).

Last edited by Clark455; February 23rd, 2017 at 06:10 PM.

#35

Back from extinction :)~

http://www.hydratechbraking.com/images/camthrustplate.JPG

http://www.hydratechbraking.com/images/camthrustplate2.JPG

After a TON of research into materials, I decided to have these run an expensive heavy duty bearing grade bronze material. I also changed the design a bit, as the factory thrust plate provided a whopping .030" of end play, which I modified in our design down to .010" end play. The OEM version was made out of an annealed steel - Rockwell hardness testing was surprisingly soft at 38.

I have eleven of these in stock as of this writing, because I haven't had time to even post about them yet, much less market them. Let me know if you are interested - $105 plus UPS ground shipping. If / when these do go into regular production, costs may come down with larger production runs. And yes,the stock non roller oil gallery plugs work just fine to mount it. Private message or e-mail if interested.

NOTE: WILL NOT FIT THE 403 DUE TO REVISED OIL GALLERY LOCATIONS

Paul M. Clark

Hydratech Braking Systems

www.hydratechbraking.com

admin@hydratechbraking.com

http://www.hydratechbraking.com/images/camthrustplate2.JPG

After a TON of research into materials, I decided to have these run an expensive heavy duty bearing grade bronze material. I also changed the design a bit, as the factory thrust plate provided a whopping .030" of end play, which I modified in our design down to .010" end play. The OEM version was made out of an annealed steel - Rockwell hardness testing was surprisingly soft at 38.

I have eleven of these in stock as of this writing, because I haven't had time to even post about them yet, much less market them. Let me know if you are interested - $105 plus UPS ground shipping. If / when these do go into regular production, costs may come down with larger production runs. And yes,the stock non roller oil gallery plugs work just fine to mount it. Private message or e-mail if interested.

NOTE: WILL NOT FIT THE 403 DUE TO REVISED OIL GALLERY LOCATIONS

Paul M. Clark

Hydratech Braking Systems

www.hydratechbraking.com

admin@hydratechbraking.com

Last edited by Clark455; May 28th, 2017 at 07:50 PM.

#37

http://www.hydratechbraking.com/images/camthrustplate.JPG

http://www.hydratechbraking.com/images/camthrustplate2.JPG

After a TON of research into materials, I decided to have these run an expensive heavy duty bearing grade bronze material. I also changed the design a bit, as the factory thrust plate provided a whopping .030" of end play, which I modified in our design down to .010" end play. The OEM version was made out of an annealed steel - Rockwell hardness testing was surprisingly soft at 38.

I have eleven of these in stock as of this writing, because I haven't had time to even post about them yet, much less market them. Let me know if you are interested - $105 plus UPS ground shipping. If / when these do go into regular production, costs may come down with larger production runs. And yes,the stock non roller oil gallery plugs work just fine to mount it. Private message or e-mail if interested.

NOTE: WILL NOT FIT THE 403 DUE TO REVISED OIL GALLERY LOCATIONS

Paul M. Clark

Hydratech Braking Systems

www.hydratechbraking.com

admin@hydratechbraking.com

http://www.hydratechbraking.com/images/camthrustplate2.JPG

After a TON of research into materials, I decided to have these run an expensive heavy duty bearing grade bronze material. I also changed the design a bit, as the factory thrust plate provided a whopping .030" of end play, which I modified in our design down to .010" end play. The OEM version was made out of an annealed steel - Rockwell hardness testing was surprisingly soft at 38.

I have eleven of these in stock as of this writing, because I haven't had time to even post about them yet, much less market them. Let me know if you are interested - $105 plus UPS ground shipping. If / when these do go into regular production, costs may come down with larger production runs. And yes,the stock non roller oil gallery plugs work just fine to mount it. Private message or e-mail if interested.

NOTE: WILL NOT FIT THE 403 DUE TO REVISED OIL GALLERY LOCATIONS

Paul M. Clark

Hydratech Braking Systems

www.hydratechbraking.com

admin@hydratechbraking.com

#40

Hi Michael, good news - I still have three left from the original run. Send me an e-mail to admin "at" hydratechbraking dot com and we can make arrangements to get one into your hands. Interesting that I haven't heard anything about these for years until a couple of weeks ago, now receiving e-mails regarding these all of a sudden. Are these being discussed somewhere else now? If so, I would be curious to know where, as I have been on the fence about producing any more of these.

Paul

Paul