Vacuum Advance Cannister Question

#1

Vacuum Advance Cannister Question

I was setting the timing on my 66 442, stock distributor with Pertronix. When I unhooked the vac advance line, (from the Edelbrock 750) I noticed no differrence in RPM. Normally it would go down, right? There is some vacuum being sucked at the port on the carb, but it doesn't seem like a lot. I figured that maybe the vac advance cannister was locked up. I pulled the distributor and tore it all down. The cannister arm has movement, but it seems pretty stiff. I bought a new cannister and it seems as stiff as the original. Are they normally pretty stiff to actuate?

#3

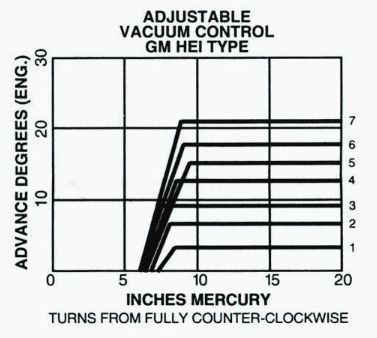

Randy, did you purchase the adjustable vacuum canister? They make basically two models - non-adjustable & adjustable. The adjustable types, IIRC, have the octagonal shaped housing where the metal vacuum tube orifice is located (the non-adjustable do not have the octagonal shape). The instructions should indicate the maximum & minimum you can adjust the adjustable vacuum canisters. There should be an Allen Wrench opening where the orifice is located to adjust the vacuum canister. Check the instruction manual to see what it is set at from the manufacturer.

#4

Randy, did you purchase the adjustable vacuum canister? They make basically two models - non-adjustable & adjustable. The adjustable types, IIRC, have the octagonal shaped housing where the metal vacuum tube orifice is located (the non-adjustable do not have the octagonal shape). The instructions should indicate the maximum & minimum you can adjust the adjustable vacuum canisters. There should be an Allen Wrench opening where the orifice is located to adjust the vacuum canister. Check the instruction manual to see what it is set at from the manufacturer.

#5

I was setting the timing on my 66 442, stock distributor with Pertronix. When I unhooked the vac advance line, (from the Edelbrock 750) I noticed no differrence in RPM. Normally it would go down, right? There is some vacuum being sucked at the port on the carb, but it doesn't seem like a lot. I figured that maybe the vac advance cannister was locked up. I pulled the distributor and tore it all down. The cannister arm has movement, but it seems pretty stiff. I bought a new cannister and it seems as stiff as the original. Are they normally pretty stiff to actuate?

#6

#7

Incorrect, the adjustment is for the amount of vacuum it takes to actuate the arm. It should not be used to adjust the amount of advance. To adjust the amount of advance you should install a mechanical limiter.

#8

#9

#10

OK Agree. I think I explained it incorrectly. Yes, you tighten and loosen the spring inside the diaphragm of the canister, right? The more you tighten the spring the later the advance the more you loosen the spring the earlier the advance, right? But, I still have a question. The vacuum being applied is going to remain the same is it not? The only delta is the spring's ability to allow the actuator rod throw to extend earlier (and full travel) as opposed to a tighter spring which would make the advance come in later (and less travel). Am I right about this? The vacuum remains the same, it's just when the advance comes in based upon spring tension, isn't it?

#11

It sure can be confusing using the google machine. While I was waiting for this to be worked thru, I went online and did a search about adjustable cans. I actually found both versions of the results of adjusting the cans. I think the consensus was that Eric's version is correct, that the adjustable cans vary the amount of vacuum needed for a certain amount of advance. The total amount of advance is limited by mechanical means outside of the cannister.......... back to work ............

#12

Kind of a good question for me (at least), because I've never considered it from the point of the 'amount' of vacuum being applied. I can see in your discussion, if you have less than optimal vacuum, you could loosen the spring tension based upon a low vacuum you are pulling, I guess. On the other hand, if you had a high vacuum, you could tighten the spring tension. I've never thought it in this sense. I just always considered whatever vacuum you had the vacuum would remain constant and nearly the same for many vehicles. Interesting.

#13

Ah, I think I figured it out. Even if vacuum remains the same, it's the 'rate', at which the advance comes in. Less tension on the spring means the advance comes in earlier at a lower vacuum. Kind of hard talking about it since I was thinking the vacuum itself from the hose remains the same (which it most likely does) but the 'amount' of vacuum required is lower when the spring has less tension. Argh. Tough one to think threw for my shallow mind.

#14

Ah, I think I figured it out. Even if vacuum remains the same, it's the 'rate', at which the advance comes in. Less tension on the spring means the advance comes in earlier at a lower vacuum. Kind of hard talking about it since I was thinking the vacuum itself from the hose remains the same (which it most likely does) but the 'amount' of vacuum required is lower when the spring has less tension. Argh. Tough one to think threw for my shallow mind.

#16

#17

This is a spring, a vacuum diaphragm, and an adjustable stop. It works exactly that way ASSUMING the vacuum source is stable. Obviously a radical cam doesn't provide a stable vacuum source (which is why W-30 carbs didn't have power pistons). The quality of the vacuum (or lack thereof) doesn't change the physics of how the adjustable mechanism works.

#18

Actually, there were three different power piston springs available for different "applications" from Rochester. I don't remember where I got the Rochester power piston spring numbers, could have been from Doug Roe's book. I don't remember seeing anything in stuff that came from Oldsmobile.

One spring was available for as low as 8" of vacuum. With a longer duration cam, you can have stable vacuum, you just don't have much of it. Thats why power brakes "didn't work well" with the 328/328 cam. The 68 H/O (W-45 non A/C) were kinda borderline with the 308/308 degree cam.

......Just my two cents worth.

One spring was available for as low as 8" of vacuum. With a longer duration cam, you can have stable vacuum, you just don't have much of it. Thats why power brakes "didn't work well" with the 328/328 cam. The 68 H/O (W-45 non A/C) were kinda borderline with the 308/308 degree cam.

......Just my two cents worth.

#19

This is a spring, a vacuum diaphragm, and an adjustable stop. It works exactly that way ASSUMING the vacuum source is stable. Obviously a radical cam doesn't provide a stable vacuum source (which is why W-30 carbs didn't have power pistons). The quality of the vacuum (or lack thereof) doesn't change the physics of how the adjustable mechanism works.

#20

This may not help, but I mostly eliminated part-throttle ping by changing to different, Non-Olds, fixed vacuum canisters in my HEI. See the article by Lars Grimsrud that shows the degrees advance for each canister and vacuum settings. The adjustable ones, having tried many settings, just didn’t work for me - they all pinged mid-throttle on a hot day. But we have cr*p gas in CA these days too, so I’m sorta chasing my tail.

If you’re pinging, you’ve got too much advance too soon, which means you want an canister that gives less advance and/or later in the RPM range.

Note that distributor advance degrees are exactly half of crankshaft advance degrees, so be ready to understand that 6 on the dizzy means 12 on the crank & so on. This is confusing, don’t forget to account for it.

Hope that helps. It was an eye opener to me that there were so many different canisters for the HEI distributor. It was really just a matter of getting a few and trying them. I’m not sure I’m at optimal yet, but the cars sure ping a lot less.

cheers

cf

If you’re pinging, you’ve got too much advance too soon, which means you want an canister that gives less advance and/or later in the RPM range.

Note that distributor advance degrees are exactly half of crankshaft advance degrees, so be ready to understand that 6 on the dizzy means 12 on the crank & so on. This is confusing, don’t forget to account for it.

Hope that helps. It was an eye opener to me that there were so many different canisters for the HEI distributor. It was really just a matter of getting a few and trying them. I’m not sure I’m at optimal yet, but the cars sure ping a lot less.

cheers

cf

#21

Thread

Thread Starter

Forum

Replies

Last Post

ReallyWildStuff

Big Blocks

4

August 22nd, 2017 06:35 AM