Dead cylinder on my 394

#1

Dead cylinder on my 394

It appears the #1 cylinder has mysteriously gone dead all of the sudden, started running rough all of the sudden and found #1 misfiring. Did compression test, #1 hardly puts out 20psi while the rest on that side are 115-120 psi. there arent any obvious valvetrain noises or anything, just no compression from #1. Plugs looked ok, tanish/white and #1 didnt really look any different from the others so i think it was running fine up until this. Im going to try a leakdown test with it at tdc on #1 with the valve cover off and see if i find any obvious leaks, im praying its just a valve not seating fully for some silly reason, and that nothings actually bent/burned. (It did ping here and there under heavy load from todays crappy fuels, i fear a valve may have finally kicked the bucket). Just figured id share with you guys my plight, maybe you guys have a trick for diagnosing loss of compression. Thanks!

#3

I looked under the valve cover and the springs look to be ok. There isnt any real tapping or knocking or smoke from the tailpipe. A valve either has to be stuck in the open position or isn't seating and letting practically all the compression out. Either way its looking more like the head has to come off unfortunately for me. Just unsure of what parts i would need until i do, i dont want to start ordering a heap if parts in advance unless i just atart replacing it all.

#5

No i didnt crank it while the cover was off. Im only hoping that its a valve stuck or lifter not lifting. The lack of noise or even any real stumbling is strange. Just praying the cam is ok, i think the rings and piston are fine because theres no smoke or knocking. im leaning more towards a bad lifter as 442harv suggested. Disassembly will tell for sure and the compression test made that obvious so im going to try a leakdown test with the cover off at tdc on #1 to see f i can pinpoint what the issue could be, then ill pull the head. Ill need manifold gaskets, head gaskets, and then see what is failing at that point. My machine shop guy can prob get the valves/lifters, and do the work. I just want good replacement parts to do it. Im not going to touch the other side if i dont have to, it was a really healthy motor up to this point. I guess this is typical of a 100,000 mile 5" yr old high compression engine though. Not that complicated, its not rocket science after all! Or is it? 😂

#6

Using a spark plug adapter, put air in the cylinder with the rocker arms on the cylinder being tested in the closed position and see where it leaks. It will leak from any of these:

tailpipe (exhaust valve),

carb (intake valve),

crankcase/breather (ring/piston), and or

cooling system (head gasket/cracked head/block).

Don't get concerned about a cracked block or head, that is the least likely.

Good luck and keep us posted!!!

tailpipe (exhaust valve),

carb (intake valve),

crankcase/breather (ring/piston), and or

cooling system (head gasket/cracked head/block).

Don't get concerned about a cracked block or head, that is the least likely.

Good luck and keep us posted!!!

#8

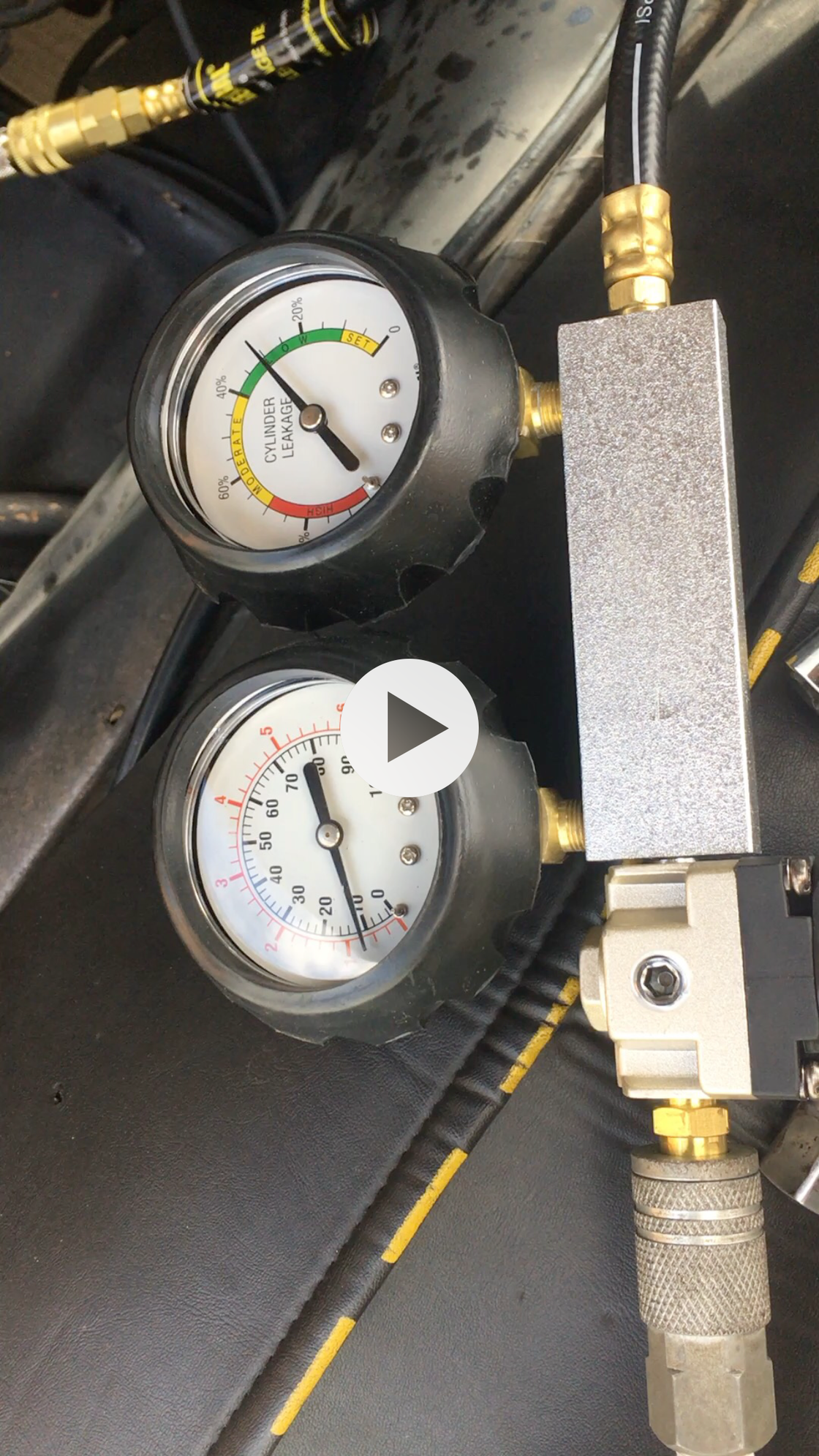

its hard to tell with it running roughly and misfiring, but i guess you could say that. I have a leak-down tester, and ill set it to tdc (which for cylinder 1 should be the timing mark), take the cover off and see if a valve has an obvious leak. really hoping i only have to just replace the lifters for #1 and put it back together. Only trying to replace whats actually failing.

#9

You can use the balancer to set number 1 close to TDC but remember the balancer may have slipped some and the timing chain is stretched. There is a 50/50 chance #1 will be at TDC on the compression stroke. Confirm #1 is on the compression stroke and your test result will be reliable. You don't want the cylinder being tested possibly on the exhaust stroke.

Good luck!!!

Good luck!!!

#10

You can use the balancer to set number 1 close to TDC but remember the balancer may have slipped some and the timing chain is stretched. There is a 50/50 chance #1 will be at TDC on the compression stroke. Confirm #1 is on the compression stroke and your test result will be reliable. You don't want the cylinder being tested possibly on the exhaust stroke.

Good luck!!!

Good luck!!!

#12

Not sure how to get a video on here, but after observing the valves while cranking it actually appears as though both are opening up. I'm sort of lost at what i should do, the compression is gone and im now unsure why. They both seem to function fine, and hold up to a leakdown test. Its as if the valve timing was off for just #1 valves

Last edited by 63super88; November 19th, 2017 at 01:02 PM.

#13

I'd redo the compression test. It is possible that a valve was sticking open or had carbon on the seat. If the compression is still low, try replacing the valve springs.

The chance of it being lifter related is low especially if you don't hear ticking etc.

Keep diagnosing until you find the problem before pulling it apart.

Good luck!!!

The chance of it being lifter related is low especially if you don't hear ticking etc.

Keep diagnosing until you find the problem before pulling it apart.

Good luck!!!

#14

I'd redo the compression test. It is possible that a valve was sticking open or had carbon on the seat. If the compression is still low, try replacing the valve springs.

The chance of it being lifter related is low especially if you don't hear ticking etc.

Keep diagnosing until you find the problem before pulling it apart.

Good luck!!!

The chance of it being lifter related is low especially if you don't hear ticking etc.

Keep diagnosing until you find the problem before pulling it apart.

Good luck!!!

#16

Ill try it again tomorrow, see if that gets a response. It held up well to the leakdown test, didnt seem to leak air into the crankcase any more than the others and read about the same on the tester. Im beginning to think maybe its not mechanically related at all, maybe theres a leak in the head gasket, it had a habit of pinging under a load and i think possibly pre-detonation may have caused the gasket to fail somehow. I'll probably try the leakdown test again as well, and this time closely check the coolant for air bubbles.

Last edited by 63super88; November 20th, 2017 at 02:46 PM.

#17

Ran into this once that turned out to be a bad valve spring, I hope you are that lucky!!!

Can you put compressed air directly into the cylinder without any testers to try to detect a leak? I'm wondering if the tester is limiting the air flow too much for the leak to be heard.

Try the oil in the cylinder too as suggested for a wet test, it will go up a little every time e.g., 20 lbs or so but if you get a big jump 50 lbs or more that indicates rings.

Keep us posted!

Can you put compressed air directly into the cylinder without any testers to try to detect a leak? I'm wondering if the tester is limiting the air flow too much for the leak to be heard.

Try the oil in the cylinder too as suggested for a wet test, it will go up a little every time e.g., 20 lbs or so but if you get a big jump 50 lbs or more that indicates rings.

Keep us posted!

#18

Ran into this once that turned out to be a bad valve spring, I hope you are that lucky!!!

Can you put compressed air directly into the cylinder without any testers to try to detect a leak? I'm wondering if the tester is limiting the air flow too much for the leak to be heard.

Try the oil in the cylinder too as suggested for a wet test, it will go up a little every time e.g., 20 lbs or so but if you get a big jump 50 lbs or more that indicates rings.

Keep us posted!

Can you put compressed air directly into the cylinder without any testers to try to detect a leak? I'm wondering if the tester is limiting the air flow too much for the leak to be heard.

Try the oil in the cylinder too as suggested for a wet test, it will go up a little every time e.g., 20 lbs or so but if you get a big jump 50 lbs or more that indicates rings.

Keep us posted!

#20

This cylinder was prone to 'ping'. I guess that could have cause the rings to fail in that cylinder, probably more broken and less stuck. Which would spell disaster for my poor 394 if thats the case. Im not ready for bottom end work on this car.

#21

Don't give up on the engine too soon, the 394 can take a lot of abuse and still be repairable.

#22

Pinging may cause the piston ring grooves to crack. Fill a 16oz container with tap water and run the engine to temp. Raise the engine idle by hand high enough to slowly dribble the water into the carb until the container is empty. Pour some wait for the idle to recover then pour a little more. Do not pour so fast as to hydrolock or stall.

#23

Remove 2 qts of oil and add 2 qts of Rislone engine treatment concentrate. See if you can drive it for about 100 miles and then change your oil.

https://smedia3.webcollage.net/956aa...pplication/pdf

https://smedia3.webcollage.net/956aa...pplication/pdf

https://smedia3.webcollage.net/956aa...pplication/pdf

https://smedia3.webcollage.net/956aa...pplication/pdf

#24

Even if an additive did manage to free the sticky rings, it still needs mechanical attention. So it looks like im doomed to pulling that piston 😥

#26

I bought a "running engine" from a 63 Starfire .

I considered it a "core" because I wanted to re-build it anyway . It is going into a " full on " restoration.

As I was tearing it down I noticed that it seemed to have two "Ridges" , one below the other in many cylinders .

When I removed the pistons I discovered why . All eight top rings were broken in half .

It appeared that the engine was probably ran in this condition for thousands of miles , because the second rings had worn their own "ridge".

Not only that , but some of the top ring grooves were worn so badly , that the ends of the broken ring pieces actually overlapped each other.

I can only speculate as to the cause . But , I suspect that someone attempted to run regular gas in the car . It probably "pinged" like he!! until it broke all eight top rings .

After that , there probably wasn't enough compression to cause detonation.

Yes, these 394 engines are "tough" .

I considered it a "core" because I wanted to re-build it anyway . It is going into a " full on " restoration.

As I was tearing it down I noticed that it seemed to have two "Ridges" , one below the other in many cylinders .

When I removed the pistons I discovered why . All eight top rings were broken in half .

It appeared that the engine was probably ran in this condition for thousands of miles , because the second rings had worn their own "ridge".

Not only that , but some of the top ring grooves were worn so badly , that the ends of the broken ring pieces actually overlapped each other.

I can only speculate as to the cause . But , I suspect that someone attempted to run regular gas in the car . It probably "pinged" like he!! until it broke all eight top rings .

After that , there probably wasn't enough compression to cause detonation.

Yes, these 394 engines are "tough" .

Last edited by Charlie Jones; November 21st, 2017 at 04:37 PM.

#27

I bought a "running engine" from a 63 Starfire .

I considered it a "core" because I wanted to re-build it anyway . It is going into a " full on " restoration.

As I was tearing it down I noticed that it seemed to have two "Ridges" , one below the other in many cylinders .

When I removed the pistons I discovered why . All eight top rings were broken in half .

It appeared that the engine was probably ran in this condition for thousands of miles , because the second rings had worn their own "ridge".

Not only that , but some of the top ring grooves were worn so badly , that the ends of the broken ring pieces actually overlapped each other.

I can only speculate as to the cause . But , I suspect that someone attempted to run regular gas in the car . It probably "pinged" like he!! until it broke all eight top rings .

After that , there probably wasn't enough compression to cause detonation.

Yes, these 394 engines are "tough" .

I considered it a "core" because I wanted to re-build it anyway . It is going into a " full on " restoration.

As I was tearing it down I noticed that it seemed to have two "Ridges" , one below the other in many cylinders .

When I removed the pistons I discovered why . All eight top rings were broken in half .

It appeared that the engine was probably ran in this condition for thousands of miles , because the second rings had worn their own "ridge".

Not only that , but some of the top ring grooves were worn so badly , that the ends of the broken ring pieces actually overlapped each other.

I can only speculate as to the cause . But , I suspect that someone attempted to run regular gas in the car . It probably "pinged" like he!! until it broke all eight top rings .

After that , there probably wasn't enough compression to cause detonation.

Yes, these 394 engines are "tough" .

#28

If a ring(s) is stuck due to carbon and it gets freed up then a mechanical fix is not needed.

If a ring is broken then yes a mechanical repair is needed. If the cylinder wall is in decent shape it could be deglazed, the piston replaced if necessary, a new set of rings on the one cylinder. An advantage to reusing the piston if it is good is the wall clearance is good, the weight is the same, the compression ratio is the same and well...you don't have to source a piston for an engine over fifty years old.

If the old piston is ok and you don't want to do an overhaul now, reuse the piston.

If you try the water/steam cleaning be very careful, it works but can damage the motor. Don't exceed a dribble of water as old cutlass advised. Another way is to put a solvent in that cylinder through the spark plug hole let it sit for a few days, crank it over to blow the solvent out (disconnect the coil wire), put the plug back in it and run it then retest.

Good luck!!!

If a ring is broken then yes a mechanical repair is needed. If the cylinder wall is in decent shape it could be deglazed, the piston replaced if necessary, a new set of rings on the one cylinder. An advantage to reusing the piston if it is good is the wall clearance is good, the weight is the same, the compression ratio is the same and well...you don't have to source a piston for an engine over fifty years old.

If the old piston is ok and you don't want to do an overhaul now, reuse the piston.

If you try the water/steam cleaning be very careful, it works but can damage the motor. Don't exceed a dribble of water as old cutlass advised. Another way is to put a solvent in that cylinder through the spark plug hole let it sit for a few days, crank it over to blow the solvent out (disconnect the coil wire), put the plug back in it and run it then retest.

Good luck!!!

#29

NOS valves , guides , cam bearings , rocker arms , and shafts , courtesy of E-Bay .

Gaskets , rod bearings , oil pump , and shaft , from O'Reilly's

Frost plugs from Fusick Automotive .

Main bearings from Falcon Global.

I went with the forged Ross pistons . Because i could "hammer on it " , and not worry about breaking cheap , off-shore cast pistons .

In fact , my whole goal here was to find as many "Made in USA." parts as possible .

Thread

Thread Starter

Forum

Replies

Last Post

Tedisthebestkingintheworl

Small Blocks

6

May 29th, 2014 01:43 PM