1/2 Line, Regulator, and Electric Pump Install

#41

Just a few general comments. First off the fire wall is a terrible place for the regulator. Not only is it in the path of destruction for a blown fly wheel or flex plate it is a high heat area. Heat and fuel is a bad mix in a performance vehicle. You don't have to be on a drag strip for flex plate or flywheel to disintegrate.

As far as return line size it can be same size, or one size smaller for carburetor applications.

I've not encounter a pump yet that will not draw fuel 8-10" above the fuel level. Once they are primed the fuel in the lines before and after the pump keep it primed so the short lift is really no problem. So don't sweat it. It'll be fine.

As far as return line size it can be same size, or one size smaller for carburetor applications.

I've not encounter a pump yet that will not draw fuel 8-10" above the fuel level. Once they are primed the fuel in the lines before and after the pump keep it primed so the short lift is really no problem. So don't sweat it. It'll be fine.

#42

I used braided fuel line and ran the lines on my car through the frame clear to the front of the cross member just like the factory did. Was a real PIA but it is well protected from damage and heat this way.I put the regulator on the inner fender because it was convenient and then to the carb from there. In the rear of the car I also fed the lines inside the frame rails up and over the rear end and brought them out a hole to go to the gas tank. Once again, it was a pia but it is procted from road debris and what ever else could hit it back there.

When I was doing all of this my car was actually intended to be a street and strip car.

When I was doing all of this my car was actually intended to be a street and strip car.

#43

Very true and good point on the flexplate/flywheel, and believe NHRA rules state it needs to be protected. BUT, if you look at where the OE lines come out of the framerail from the front of the car, you will see it's exposed just as much if not more than being on the firewall. It's certainly further forward than the firewall, can see the hole on the frame in the first series of pics I posted.

If you really wanted to, you could use rock guard on the fuel lines in the same locations the factory did, rock guard is available from a number of sources, all the brake line repop places offer it.

True to about heat, there again though, if it's under the hood, it's going to heat soak regardless of where you put it, period. I have the same config on the LeMans, regulator on the firewall, and I've used an IR gun to read temps of the regulator, and it's less than the intake, that's for sure. The front fuel bowl gets hotter. And with a return system, it circulating helps keep it cool. (Yes, there is potential for heat soak of fuel in the tank, especially when it's low, but it's still better than deadhead.)

And finally true, on the return line sizes, same or one size smaller is acceptable. If you look at recommendations from the big manufacturers of fuel system hardware, that's their' stance. I should have commented on that when I commented on the pump feed line sizing, thanks for pointing that out.

One thing though, you should run as much hard line as possible, for a number of reasons. One, from a safety standpoint, braided line wears out much faster than hard line, and believe there's even replacement interval info in the NHRA book. Two is weight, that stuff weighs a ton more than aluminum line. It's harder to route, it's much larger in size. Then there's cost.

Everyone keep the comments coming, it's certainly becoming an informative thread!

.

If you really wanted to, you could use rock guard on the fuel lines in the same locations the factory did, rock guard is available from a number of sources, all the brake line repop places offer it.

True to about heat, there again though, if it's under the hood, it's going to heat soak regardless of where you put it, period. I have the same config on the LeMans, regulator on the firewall, and I've used an IR gun to read temps of the regulator, and it's less than the intake, that's for sure. The front fuel bowl gets hotter. And with a return system, it circulating helps keep it cool. (Yes, there is potential for heat soak of fuel in the tank, especially when it's low, but it's still better than deadhead.)

And finally true, on the return line sizes, same or one size smaller is acceptable. If you look at recommendations from the big manufacturers of fuel system hardware, that's their' stance. I should have commented on that when I commented on the pump feed line sizing, thanks for pointing that out.

One thing though, you should run as much hard line as possible, for a number of reasons. One, from a safety standpoint, braided line wears out much faster than hard line, and believe there's even replacement interval info in the NHRA book. Two is weight, that stuff weighs a ton more than aluminum line. It's harder to route, it's much larger in size. Then there's cost.

Everyone keep the comments coming, it's certainly becoming an informative thread!

.

#44

While braded may weigh a tad more it won't wear through from vibration like aluminum will. On a street car I'd be sure to put a lot of clamps on the line for just that reason.

On my '67 the front frame rails extend well behind the flywheel area. In the front the fuel line exited in front of the K member. I'm surprised that the later cars would be any different and expose the fuel line in that area. My '76 was the same way as the '67 in that respect.

On my '67 the front frame rails extend well behind the flywheel area. In the front the fuel line exited in front of the K member. I'm surprised that the later cars would be any different and expose the fuel line in that area. My '76 was the same way as the '67 in that respect.

#45

While braded may weigh a tad more it won't wear through from vibration like aluminum will. On a street car I'd be sure to put a lot of clamps on the line for just that reason.

On my '67 the front frame rails extend well behind the flywheel area. In the front the fuel line exited in front of the K member. I'm surprised that the later cars would be any different and expose the fuel line in that area. My '76 was the same way as the '67 in that respect.

On my '67 the front frame rails extend well behind the flywheel area. In the front the fuel line exited in front of the K member. I'm surprised that the later cars would be any different and expose the fuel line in that area. My '76 was the same way as the '67 in that respect.

For clamps, I used all the factory locations, do we think it's not enough? Think I should use more? I thought it was enough, but am asking since it's been brought up. I was thinking that you don't want the clamps tight on the lines, because as the chassis moves around, it will stress the lines. Am I wrong in thinking so? Now I'm curious.

The attached pic is of the frame rail, and the red circle is where the OE lines enter the frame rail to go forward to the OE mech pump. It's definitely forward of the firewall, and it is in line with the flexplate area. Certainly less would be exposed if it were in the OE location compared with where it's currently mounted, but this car will never see slicks, and never have a high stall converter, so risk for a flexplate explosion is low (I run an SFI in all my cars). At the track, most would run a blanket, and street or strip, I would hope all would run a blowproof for a manual car.

Another thing to keep in mind is if you run lines through the frame rail, it goes right by/next to the coil spring and pocket, so one would have to make sure to secure the lines away from that moving part.

Some braided line manufacturers recommend a 12-18 month replacement interval, and though many 'get away' with running it much longer than that, that's the manufacturer's recommendation, and believe that's what NHRA states, to follow the manufacturer's recommendation for service.

Some may have seen the article in Hot Rod magazine a few years ago:

http://www.hotrod.com/techarticles/e...ce_fuel_hoses/

Hard lines statements are to visually inspect and replace as needed.

Aeroquip AQP -08 AN stainless braided line weighs .19 lbs per foot. Aluminum line is a fraction of that. Whole reason they came out with Starlite hose.

.

#48

3 kinds of fuel pump safety switches, oil psi, tach signal, and inertia. The best ones to use are inertia, and pretty easy to wire. You can junk yard one off a newer car, or buy a new replacement one from an auto parts store.

(examples, can shop for better prices)

Summit Racing/Ford Inertia Switch:

http://www.summitracing.com/parts/sum-890145/overview/

Pigtail connector for Inertia Switch:

http://www.summitracing.com/parts/pco-5756pt/overview/

Oil PSI:

http://www.ebay.com/itm/JEGS-Perform...e1cb88&vxp=mtr

Tach Signal:

http://www.ebay.com/itm/12v-Electric...ad630d&vxp=mtr

Oh, there's a roll over type switch too.

http://www.summitracing.com/parts/prf-80160/overview/

.

(examples, can shop for better prices)

Summit Racing/Ford Inertia Switch:

http://www.summitracing.com/parts/sum-890145/overview/

Pigtail connector for Inertia Switch:

http://www.summitracing.com/parts/pco-5756pt/overview/

Oil PSI:

http://www.ebay.com/itm/JEGS-Perform...e1cb88&vxp=mtr

Tach Signal:

http://www.ebay.com/itm/12v-Electric...ad630d&vxp=mtr

Oh, there's a roll over type switch too.

http://www.summitracing.com/parts/prf-80160/overview/

.

Last edited by HWYSTR455; April 1st, 2014 at 11:52 AM.

#50

#52

I noticed the links on post #48 for ebay for some of the switches were no longer valid, so I posted links to the switches on Summit Racing. That includes the pigtail/connector for the switch, part numbers, and also a link to the Painless rollover switch.

.

.

#56

Update:

Well, as someone previously mentioned, there's an issue with the RobbMC pickup, where once you go below a 1/2 a tank, it will suck air. That in fact is the case, I experienced sucking air between 1/4-1/2 a tank. Was a pain on the power tour, having to stop every 160 miles or so and fill up. (4k RPM @ 80+ I got roughly 13mpg)

Before I went on the power tour, I called Tanks, Inc and ordered a fuel injection tank. I was hoping to have it installed before I went on the power tour, but, they seem to be popular, they were backordered by several weeks.

Also ordered a fuel sender and pickup assembly (non-EFI), and though they list the pickups as 3/8 line, they are in fact 1/2" inside diameter (@ .480 to be exact).

Later, if I want, I can go EFI, either port or throttle body, the car is ready for it, especially since I now have the O2 bung installed too. (was using an LM-1 wide band to dial the carb in.)

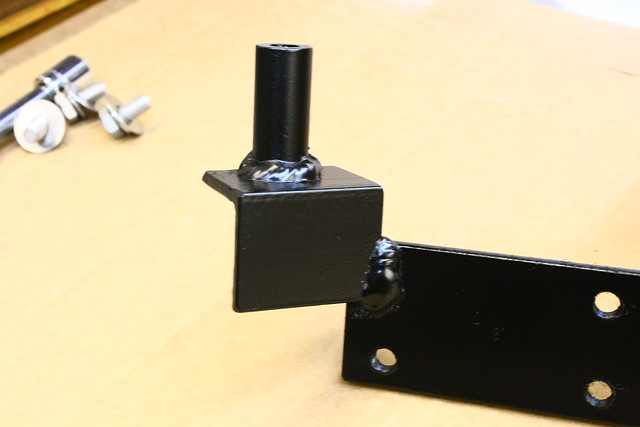

Today, tank finally came in, they have them in stock again, if any are interested. ($225). Got the sending unit adjusted and mounted, and the pickup & return assembly. Also had to do some brass fittings since the AN adapters were bottoming on the mounting plate before they tightened. Works for me, since the fittings are very close to where the existing fittings are, and the existing lines will mate right up without doctoring them. Nice.

Should have it in by end of day Saturday, will slowly fill and run it, check the sender and see how far down I can go without it sucking air, will report back. But just by the looks of things, problem solved.

(pics attached)

.

Well, as someone previously mentioned, there's an issue with the RobbMC pickup, where once you go below a 1/2 a tank, it will suck air. That in fact is the case, I experienced sucking air between 1/4-1/2 a tank. Was a pain on the power tour, having to stop every 160 miles or so and fill up. (4k RPM @ 80+ I got roughly 13mpg)

Before I went on the power tour, I called Tanks, Inc and ordered a fuel injection tank. I was hoping to have it installed before I went on the power tour, but, they seem to be popular, they were backordered by several weeks.

Also ordered a fuel sender and pickup assembly (non-EFI), and though they list the pickups as 3/8 line, they are in fact 1/2" inside diameter (@ .480 to be exact).

Later, if I want, I can go EFI, either port or throttle body, the car is ready for it, especially since I now have the O2 bung installed too. (was using an LM-1 wide band to dial the carb in.)

Today, tank finally came in, they have them in stock again, if any are interested. ($225). Got the sending unit adjusted and mounted, and the pickup & return assembly. Also had to do some brass fittings since the AN adapters were bottoming on the mounting plate before they tightened. Works for me, since the fittings are very close to where the existing fittings are, and the existing lines will mate right up without doctoring them. Nice.

Should have it in by end of day Saturday, will slowly fill and run it, check the sender and see how far down I can go without it sucking air, will report back. But just by the looks of things, problem solved.

(pics attached)

.

#58

It's hard to see where I went into the frame with these pics but it is well before the converter/flexplate area. Definitely protected from the saw toothed ring gear.

IMG_20140620_090235_914_zpssqxy91g2.jpg

IMG_20140620_090343_074_zpslb5qfeoa.jpg

Here is where mine exits in the stock location. Very protected from any direct carnage. Would take an extremely major block failure to get to the fuel lines. But there is no saw toothed ring gear going to cut any of it in half. The balancer doesn't have a straight shot at it either.

IMG_20140620_085814_887_zps13nirwem.jpg

IMG_20140620_090235_914_zpssqxy91g2.jpg

IMG_20140620_090343_074_zpslb5qfeoa.jpg

Here is where mine exits in the stock location. Very protected from any direct carnage. Would take an extremely major block failure to get to the fuel lines. But there is no saw toothed ring gear going to cut any of it in half. The balancer doesn't have a straight shot at it either.

IMG_20140620_085814_887_zps13nirwem.jpg

#59

Hmmn......interesting. I have the RobbMc pickup in my '65 and routinely drag race it with 1/4-1/2 tank of fuel and have never had that issue.

#60

Steve - Yeah, the aeromotive ones are nice, I was looking at those, and they've been out longer than the Tanks, Inc ones. A little pricey, but quality units.

Smitty275 - That works. That would pass tech too. I may actually redo mine, will have to go look at it again, see what my options are.

chadman - Yeah, you don't see it on your install? How far down can you go? If you go back and look at post #8, you will see the comparison between OE and the RobbMC pickups, and that's for the 68-72s. Maybe different years are better? Maybe it's got something to do with the return? Are you running an electric setup with a return?

.

Smitty275 - That works. That would pass tech too. I may actually redo mine, will have to go look at it again, see what my options are.

chadman - Yeah, you don't see it on your install? How far down can you go? If you go back and look at post #8, you will see the comparison between OE and the RobbMC pickups, and that's for the 68-72s. Maybe different years are better? Maybe it's got something to do with the return? Are you running an electric setup with a return?

.

#61

I should close the loop on this and clarify some stuff.

Installed the new tank, pickup, etc, and am happy with all the parts. The tank is nice, and when testing the draw on the pickup etc I was able to get it down to about a gallon, I think a little less.

Test drive, went for a 3 hours cruise, and, towards the end, same issue, starved for fuel. Topped the tank off, hooked up the fuel psi gauge, and was like 3#. Left the gauge on it, drove for about 30 mins, was getting a lean out, pulled over, popped the hood, and the needle on the gauge fluttered a little at 0. Pump defective, and psi drops over time as it heats up.

Replaced the pump and went for a long drive, issues corrected. Left the gauge hooked up, drove it for hours until it was down to below a 1/4 tank, checked the psi and all is good.

One thing worth noting, the fuel sending unit Tanks have, you can't adjust the thing to where it will read the full range from E - F, and you have to source the sender from Classic Instruments directly, the one with the flat, oval float.

Also, use the cork gaskets, the rubber ones leak no matter what I did!

.

Installed the new tank, pickup, etc, and am happy with all the parts. The tank is nice, and when testing the draw on the pickup etc I was able to get it down to about a gallon, I think a little less.

Test drive, went for a 3 hours cruise, and, towards the end, same issue, starved for fuel. Topped the tank off, hooked up the fuel psi gauge, and was like 3#. Left the gauge on it, drove for about 30 mins, was getting a lean out, pulled over, popped the hood, and the needle on the gauge fluttered a little at 0. Pump defective, and psi drops over time as it heats up.

Replaced the pump and went for a long drive, issues corrected. Left the gauge hooked up, drove it for hours until it was down to below a 1/4 tank, checked the psi and all is good.

One thing worth noting, the fuel sending unit Tanks have, you can't adjust the thing to where it will read the full range from E - F, and you have to source the sender from Classic Instruments directly, the one with the flat, oval float.

Also, use the cork gaskets, the rubber ones leak no matter what I did!

.

#62

chadman - Yeah, you don't see it on your install? How far down can you go? If you go back and look at post #8, you will see the comparison between OE and the RobbMC pickups, and that's for the 68-72s. Maybe different years are better? Maybe it's got something to do with the return? Are you running an electric setup with a return?

.

#63

.

#64

#65

.

Thread

Thread Starter

Forum

Replies

Last Post

gearheads78

General Discussion

5

January 19th, 2014 07:23 PM

Nickthefish

Parts For Sale

0

January 27th, 2013 10:38 AM

1965cutlassragtop

Parts For Sale

0

July 15th, 2012 06:26 PM

j_link

Parts For Sale

1

June 14th, 2012 10:04 PM