455 build

#1

455 build

Here's the other one I did this past weekend.

.040 over Icon pistons

Ga heads with 2.07/1.68 valves, minor clean up.

10.1:1

Performer RPM intake, center divider cut 3/4"

Proform 850 mech secondary 81/90 jets

Procomp HEI dist

Flowtech 1 3/4" headers

Melling HV pump with purple spring

Toro pan with the hump cut out.

Eagle H beams

ARP main studs

Custom Lunati Hyd roller, 231/234@.050 on a 111 in at 110

Cloyes double row chain

Run on 91 pump.

.040 over Icon pistons

Ga heads with 2.07/1.68 valves, minor clean up.

10.1:1

Performer RPM intake, center divider cut 3/4"

Proform 850 mech secondary 81/90 jets

Procomp HEI dist

Flowtech 1 3/4" headers

Melling HV pump with purple spring

Toro pan with the hump cut out.

Eagle H beams

ARP main studs

Custom Lunati Hyd roller, 231/234@.050 on a 111 in at 110

Cloyes double row chain

Run on 91 pump.

Last edited by cutlassefi; November 7th, 2016 at 03:38 PM.

#2

Here's the other one I did this past weekend.

.040 over Icon pistons

Ga heads with 2.07/1.68 valves, minor clean up.

10.1:1

Performer RPM intake, center divider cut 3/4"

Proform 850 mech secondary 81/90 jets

Procomp HEI dist

Flowtech 1 3/4" headers

Melling HV pump with purple spring

Toro pan with the hump cut out.

Eagle H beams

ARP main studs

Custom Lunati Hyd roller, 231/234@.050 on a 111 in at 110

Cloyes double row chain

Run on 91 pump.

.040 over Icon pistons

Ga heads with 2.07/1.68 valves, minor clean up.

10.1:1

Performer RPM intake, center divider cut 3/4"

Proform 850 mech secondary 81/90 jets

Procomp HEI dist

Flowtech 1 3/4" headers

Melling HV pump with purple spring

Toro pan with the hump cut out.

Eagle H beams

ARP main studs

Custom Lunati Hyd roller, 231/234@.050 on a 111 in at 110

Cloyes double row chain

Run on 91 pump.

#10

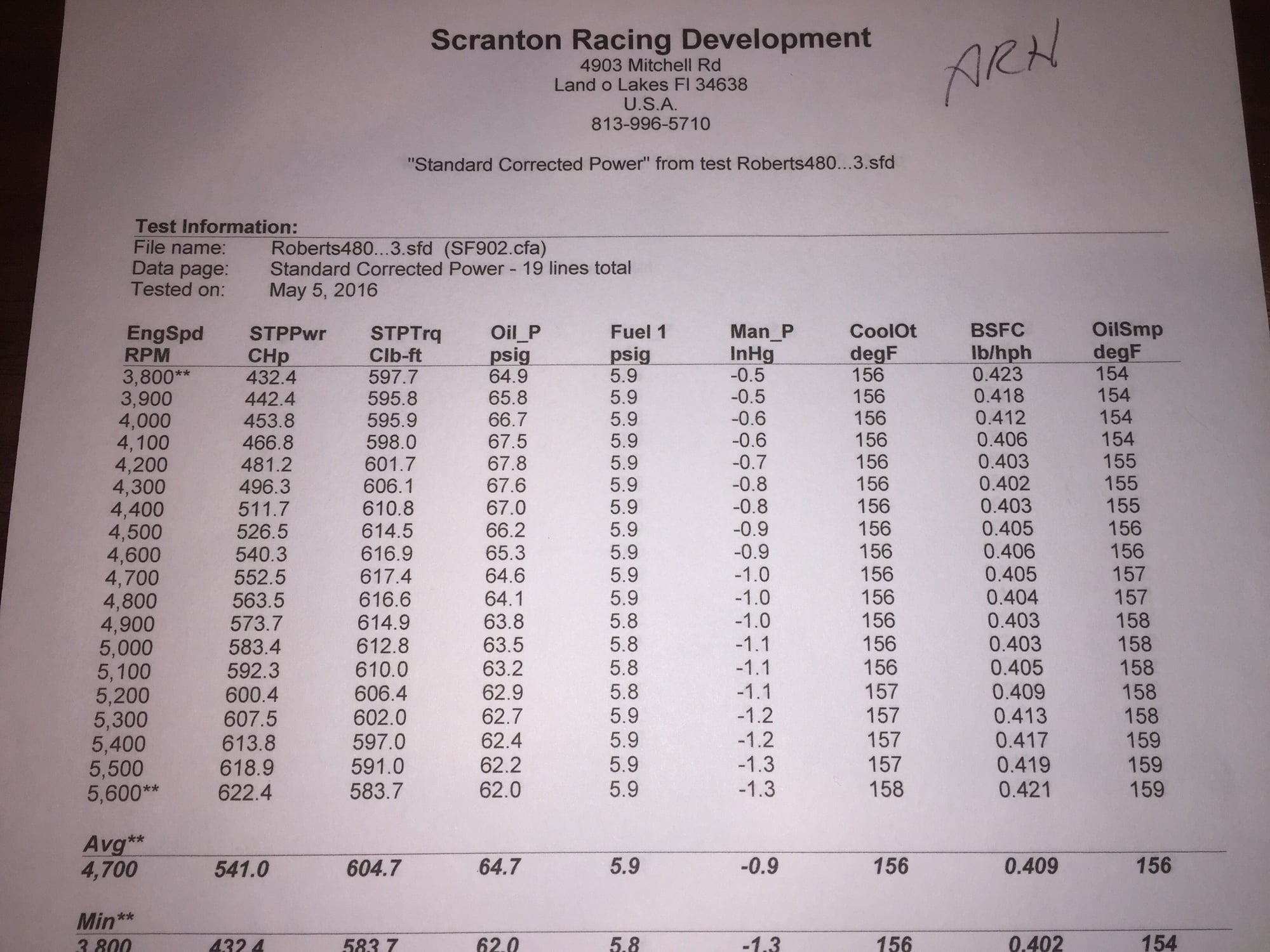

This engine has absolutely phenomenal numbers that rival that of aluminum headed engines. In fact, it is better than some Edelbrock headed engines, and very close to highly refined aluminum headed engines in terms of efficiency.

How did you get the heads to flow so much with minor cleanup?

#11

I don't believe I ever listed what they flowed.

The 480 build I posted made 620+ with heads that only flowed 285@.600. In that respect I'm agree with Bill T., in that it's not only the amount of flow but the quality of flow as well.

And as far as comparing them to an aluminum head, you of all people should know that the aluminums really don't flow much better than irons out of the box so that's a mute point in my opinion. It's only after working them over that flow numbers get to be respectable. AND you can make irons flow just about what aluminums do, right? Isn't that what you claim as well?

The RPM intake is probably better than I gave it credit for. Prior to this I never had much luck with them. This one was a good match right out of the box, with just minor surfacing.

Plus I've changed my ring pack and wall finish. According to GMrocket, he believes that's worth as much as 15-20 more. It's obviously worth something as oil temps are staying much more stable as well after I made that change.

P.S. Check out 70cutty's build. it made 493/565 on this same dyno. It had a regular Performer, the old ring pack and aluminum Procomps, unported. Compression was about the same, c.i. was the same but this had the RPM, and a better ring pack, and made about 20hp more. Seems to be pretty consistant to me.

Another one;

https://classicoldsmobile.com/forums...15-400e-2.html

Less c.i., less intake, less carb, no headers, the same ring pack and wall finish. Again seems to be pretty consistent with the rest.

The 480 build I posted made 620+ with heads that only flowed 285@.600. In that respect I'm agree with Bill T., in that it's not only the amount of flow but the quality of flow as well.

And as far as comparing them to an aluminum head, you of all people should know that the aluminums really don't flow much better than irons out of the box so that's a mute point in my opinion. It's only after working them over that flow numbers get to be respectable. AND you can make irons flow just about what aluminums do, right? Isn't that what you claim as well?

The RPM intake is probably better than I gave it credit for. Prior to this I never had much luck with them. This one was a good match right out of the box, with just minor surfacing.

Plus I've changed my ring pack and wall finish. According to GMrocket, he believes that's worth as much as 15-20 more. It's obviously worth something as oil temps are staying much more stable as well after I made that change.

P.S. Check out 70cutty's build. it made 493/565 on this same dyno. It had a regular Performer, the old ring pack and aluminum Procomps, unported. Compression was about the same, c.i. was the same but this had the RPM, and a better ring pack, and made about 20hp more. Seems to be pretty consistant to me.

Another one;

https://classicoldsmobile.com/forums...15-400e-2.html

Less c.i., less intake, less carb, no headers, the same ring pack and wall finish. Again seems to be pretty consistent with the rest.

Last edited by cutlassefi; November 9th, 2016 at 03:21 PM.

#12

I don't believe I ever listed what they flowed.

The 480 build I posted made 620+ with heads that only flowed 285@.600. In that respect I'm agree with Bill T., in that it's not only the amount of flow but the quality of flow as well.

And as far as comparing them to an aluminum head, you of all people should know that the aluminums really don't flow much better than irons out of the box so that's a mute point in my opinion. It's only after working them over that flow numbers get to be respectable. AND you can make irons flow just about what aluminums do, right? Isn't that what you claim as well?

The RPM intake is probably better than I gave it credit for. Prior to this I never had much luck with them. This one was a good match right out of the box, with just minor surfacing.

Plus I've changed my ring pack and wall finish. According to GMrocket, he believes that's worth as much as 15-20 more. It's obviously worth something as oil temps are staying much more stable as well after I made that change.

P.S. Check out 70cutty's build. it made 493/565 on this same dyno. It had a regular Performer, the old ring pack and aluminum Procomps, unported. Compression was about the same, c.i. was the same but this had the RPM, and a better ring pack, and made about 20hp more. Seems to be pretty consistant to me.

Another one;

https://classicoldsmobile.com/forums...15-400e-2.html

Less c.i., less intake, less carb, no headers, the same ring pack and wall finish. Again seems to be pretty consistent with the rest.

The 480 build I posted made 620+ with heads that only flowed 285@.600. In that respect I'm agree with Bill T., in that it's not only the amount of flow but the quality of flow as well.

And as far as comparing them to an aluminum head, you of all people should know that the aluminums really don't flow much better than irons out of the box so that's a mute point in my opinion. It's only after working them over that flow numbers get to be respectable. AND you can make irons flow just about what aluminums do, right? Isn't that what you claim as well?

The RPM intake is probably better than I gave it credit for. Prior to this I never had much luck with them. This one was a good match right out of the box, with just minor surfacing.

Plus I've changed my ring pack and wall finish. According to GMrocket, he believes that's worth as much as 15-20 more. It's obviously worth something as oil temps are staying much more stable as well after I made that change.

P.S. Check out 70cutty's build. it made 493/565 on this same dyno. It had a regular Performer, the old ring pack and aluminum Procomps, unported. Compression was about the same, c.i. was the same but this had the RPM, and a better ring pack, and made about 20hp more. Seems to be pretty consistant to me.

Another one;

https://classicoldsmobile.com/forums...15-400e-2.html

Less c.i., less intake, less carb, no headers, the same ring pack and wall finish. Again seems to be pretty consistent with the rest.

However, stick to the subject......would you agree that to make these numbers would require a fair amount of airflow?

What I am getting at is that THIS particular engine is most impressive because of the quality of airflow, along with the airflow required to make such numbers......and all you did was a minor cleanup of an iron cylinder head with 60s technology.

I understand you never mentioned flow numbers, you don't have to......physics do not lie.

#13

would you agree that to make these numbers would require a fair amount of airflow? Yes, along with reduced internal friction over the norm.

What I am getting at is that THIS particular engine is most impressive because of the quality of airflow, along with the airflow required to make such numbers......and all you did was a minor cleanup of an iron cylinder head with 60s technology. Agreed.

I understand you never mentioned flow numbers, you don't have to......physics do not lie.

What I am getting at is that THIS particular engine is most impressive because of the quality of airflow, along with the airflow required to make such numbers......and all you did was a minor cleanup of an iron cylinder head with 60s technology. Agreed.

I understand you never mentioned flow numbers, you don't have to......physics do not lie.

Last edited by cutlassefi; November 9th, 2016 at 04:53 PM.

#14

You mentioned above in your response to me this has reduced internal friction over the norm. Do you mean this particular build does more-so than your other builds? Your other builds always seem to employ reduced friction techniques which tremendously helps output.

Last edited by 80 Rocket; November 10th, 2016 at 08:14 AM.

#15

George's 400, this one, and mad Max's 480 all had the better ring packs in them and 2 with different pistons.

And even though the 480 made the most power, that one took the longest to get any temperature at all into the oil. That should tell you something right there. It had the best piston and rings of the group, along with coated bearings.

And even though the 480 made the most power, that one took the longest to get any temperature at all into the oil. That should tell you something right there. It had the best piston and rings of the group, along with coated bearings.

Last edited by cutlassefi; November 10th, 2016 at 10:03 AM.

#18

80Rocket- just finished the short block on the next build. Same style piston that's in Georges 425. Fully assembled short block with cam but no valvetrain only takes 16lbft to turn it over. That's free hp as compared to most other piston/ring combos.

#19

George's 400, this one, and mad Max's 480 all had the better ring packs in them and 2 with different pistons.

And even though the 480 made the most power, that one took the longest to get any temperature at all into the oil. That should tell you something right there. It had the best piston and rings of the group, along with coated bearings.

And even though the 480 made the most power, that one took the longest to get any temperature at all into the oil. That should tell you something right there. It had the best piston and rings of the group, along with coated bearings.

Here are the engines we are dealing with:

Georges 400= 425" BBO, 454hp/510tq mild ported C iron heads

70cutty 463= 463" BBO, 493hp/570tq unported Pro Comps

Mad Max 480= 480" BBO race engine, 622hp/617tq mild ported Edelbrock heads

455 Build= 463" BBO, 516hp/611tq Ga iron heads no porting

Before we delve in, let's talk about BMEP (Brake Mean Effective Pressure). We take IMEP (Indicated Mean Effective Pressure) and subtract FMEP (Friction Mean Effective Pressure). What the hell does this all mean????

-IMEP

IMEP is the actual force (measured in psi) the piston sees during the power phase. Factors that dictate IMEP are airflow (quantity and quality of-), compression, volumetric efficiency, combustion chamber effectiveness, etc. The more IMEP, the better......as long as it does not induce detonation.

-FMEP

FMEP has to do with frictional losses such as ring drag, bearing drag, camshaft lifters, etc. The less FMEP, the better.

-BMEP

BMEP is the average psi a piston sees during the power cycle and is calculated by:

IMEP-FMEP=BMEP

The calculation to figure BMEP on any engine is to take the torque multiplied by 150.8 and divide by the cubic inch displacement. I hope I didn't lose anyone yet, this is fun stuff. BMEP is the best way to compare any engine, of any displacement, no matter how many cylinders.......it doesn't care. It will show you how efficient an engine really is.

BMEP= torque x 150.8/ cubic inch of engine

Let's compare these engines......

Georges 400:

Peak Tq BMEP= 181.0

Peak HP BMEP= 159.6

Not bad for iron heads and some porting.

70cutty 463:

Peak Tq BMEP= 185.7

Peak HP BMEP= 162.1

I'd say very good numbers for unported Pro Comps. As you can see unported aluminums beat ported irons here.

Mad Max 480:

Peak Tq BMEP= 194.0

Peak HP BMEP= 183.3

These feature ported Edelbrocks and they are doing some work. Also, notice how the BMEP does not drop off so much at peak HP like the other engines. This was built as a race piece and it shows. ALSO, Mark stated this one really had the friction reducing stuff working for this engine as indicated by the extended amount of time it took to get some temp in the oil. Remember- imep-FMEP=bmep......reducing friction will net a gain in BMEP, even if the IMEP is the same.

455 build: (the one this thread is about)

Peak Tq BMEP= 199.0

Peak HP BMEP= 169.7

This has unported Ga heads that has a higher FMEP than the last engine we just looked at (the 480 with ported Edelbrocks!), yet STILL has a better BMEP at peak torque!! Peak torque happens to be when the engine is most efficient, and with its highest volumetric efficiency, which would mean it has its highest BMEP. This engine was no slouch at peak HP either as it beat the ported C head engine and the unported Pro Comp engine.

Think about this, if the FMEP is higher with the 455 build over the Mad Max 480, that would mean the IMEP is higher at peak torque. For illustration purposes, let's assign 455 build with an FMEP of 110 and the Mad Max 480 with a value of 90.

455 build ( x-110=199 peak torque BMEP)

Mad Max 480 ( y-90=194 peak tq BMEP)

That means the 455 build has an IMEP of 309 at peak torque and the Mad Max build has only 284. That is astounding! That means that the unported Ga heads are better than ported Edelbrocks (at peak torque) since the IMEP is higher. I can't say I have ever heard of such a thing!

Let's look at some other engines from other builders.....

Some of you may be familiar with Dale Robinsons EMC engine from 2008-

http://www.hotrod.com/articles/0911p...le-307-engine/

This engine had serious modifications done to the heads with ports welded, epoxied, moved around....here is what it did:

Peak Tq BMEP= 205.2

Peak HP BMEP= 184.7

The unported Ga heads from the 455 build are almost there with these heads that have a lot of hours into them.......as well as all of the friction reducing techniques.

Let's look at the 517" engine Bill Trovato just did for Brian Trick-

http://realoldspower.prophpbb.com/topic10087.html

Peak Tq BMEP= 207.2

Peak HP BMEP= 184.8

This engine features the BTR Edelbrocks with relocated pushrod tubes and all of the tricks of the trade for airflow and airspeed, yet the Ga unported head was still almost there at peak torque.

Here is what a stock Oldsmobile did from the factory with (obviously) unported heads, thick ring packs, crappy intake and exhaust manifolds, etc.

Peak Tq BMEP= 163.3

Peak HP BMEP= 139.2

Let this sink in as well, this 455 build has stock exhaust ports, which are terribly inadequate compared to the aluminum heads with their improved exhaust efficiency.

I simply cannot explain how impressive this 455 build is with unported Ga's (aka= 60s technology). Mark, can you explain what "minor cleanup" is? Did you throw fairy dust down the carb on that dyno pull?

Last edited by 80 Rocket; November 11th, 2016 at 06:44 PM.

#20

Here's an excellent read for anyone wanting to know more about BMEP:

http://www.epi-eng.com/piston_engine..._yardstick.htm

http://www.epi-eng.com/piston_engine..._yardstick.htm

#21

I get your sarcasm.

No pixie dust. If I remember they weren't fully ported but may have had the bowls done. I did this and the 403 the same weekend. I know for a fact the 403's were just a cartridge roll clean up with no other work. I pulled a few valves out of that one.

And say what you want about Travato. He posted a build on ROP that didn't make anymore power than Max's 480, but had more ci, compression and carburetor plus his "trick" heads. Maybe they're not so trick. Or maybe my guys' flow bench is way more conservative. Take your pick.

No pixie dust. If I remember they weren't fully ported but may have had the bowls done. I did this and the 403 the same weekend. I know for a fact the 403's were just a cartridge roll clean up with no other work. I pulled a few valves out of that one.

And say what you want about Travato. He posted a build on ROP that didn't make anymore power than Max's 480, but had more ci, compression and carburetor plus his "trick" heads. Maybe they're not so trick. Or maybe my guys' flow bench is way more conservative. Take your pick.

#22

I get your sarcasm.

No pixie dust. If I remember they weren't fully ported but may have had the bowls done. I did this and the 403 the same weekend. I know for a fact the 403's were just a cartridge roll clean up with no other work. I pulled a few valves out of that one.

And say what you want about Travato. He posted a build on ROP that didn't make anymore power than Max's 480, but had more ci, compression and carburetor plus his "trick" heads. Maybe they're not so trick. Or maybe my guys' flow bench is way more conservative. Take your pick.

No pixie dust. If I remember they weren't fully ported but may have had the bowls done. I did this and the 403 the same weekend. I know for a fact the 403's were just a cartridge roll clean up with no other work. I pulled a few valves out of that one.

And say what you want about Travato. He posted a build on ROP that didn't make anymore power than Max's 480, but had more ci, compression and carburetor plus his "trick" heads. Maybe they're not so trick. Or maybe my guys' flow bench is way more conservative. Take your pick.

There is nothing wrong with soliciting work off of a forum, but understand you should be willing and easily able to defend your work when confronted with facts about your builds.

This build in particular shows very high BMEP numbers. I was pointing that out by comparing your engine to other engines, I was not attempting to showcase Trovato in any way, I really don't care what he does. Getting back to this build shows an incredibly high BMEP at peak TQ and even peak HP for a cast iron build with "minor cleanup. Let's look at some more data:

_SnapShot_zpsmll6ajnc.png

This is a pipemax view of this engine. To achieve the peak HP number you produced requires a cfm of 254.4 through the entire intake tract. That also shows a volumetric efficiency of 106%........even if these were fully ported irons, that would be off the charts for anything I have seen.

You can claim you have all of the frictional secrets in the world, but you yourself stated that this engine had more friction than the Mad Max 480, that means this engine had a higher FMEP, so that means these irons worked better than the Edelbrocks on the Mad Max engine at peak TQ. That is why I see red flags all over the place, and you should too.

A BMEP of 199, airflow through the entire intake tract at 254.4cfm, and a volumetric efficiency of 106% is not normal for iron heads with "minor cleanup" or even just bowl work. Show me another iron headed Olds engine even remotely close. All the while, this engine is working better than aluminum heads that feature improved exhaust ports!

For reference, here is a small block Chevy with aftermarket iron Vortec (very good 90s technology) heads. The engine was done by David Vizard.

355sbc= 447hp @ 6000/ 445tq @ 4600, new EQ iron Vortec heads

Peak TQ BMEP= 189.0

Peak HP BMEP= 166.1

This 455 is beating the hell out of a Vizard built small block Chevy that has a MUCH better set of heads on it.

I am not calling you a liar here. However, my data is not subjective, these are facts, and all I am asking you to do is defend your position with facts. Something doesn't add up here as you hopefully can see. Maybe there is something I am overlooking and I will surely admit to it if pointed out.

Last edited by 80 Rocket; November 12th, 2016 at 08:42 AM.

#23

........and just so everyone knows what the plateau is for N/A engines, here are some racing engine BMEP numbers:

2006 F1 v8 146cubic inches

Peak TQ BMEP= 220.3

Peak HP BMEP= 212.0

2007 Nascar Cup Engine 358cubes

Peak TQ BMEP= 228.3

Peak HP BMEP= 211.8

2014 NHRA Pro Stock Engine 500cubes

Peak TQ BMEP= 247.3

Peak HP BMEP= 217.3

2006 F1 v8 146cubic inches

Peak TQ BMEP= 220.3

Peak HP BMEP= 212.0

2007 Nascar Cup Engine 358cubes

Peak TQ BMEP= 228.3

Peak HP BMEP= 211.8

2014 NHRA Pro Stock Engine 500cubes

Peak TQ BMEP= 247.3

Peak HP BMEP= 217.3

#24

I think one area that has not been addressed here is velocity in the port. Ports flow best with a velocity in the 280-320 FPS range. Of course this assumes the port can handle that kind of velocity. Too much velocity and the column of air slams against the port walls, especially the rear port wall, and this causes a huge disruption in air flow.

You can see this when ports drop off on the high end and the flow numbers flatten out. By high end I mean valve open numbers.

Take the Boss 302 for example. Ports were huge but the flow numbers were lacking until high rpm. The velocity was so low that they were dogs at low rpm, but by 6-7k rpm they were killers.

There is always a trade off between CFM and velocity. You have to match things to the RPM you want.

You can see this when ports drop off on the high end and the flow numbers flatten out. By high end I mean valve open numbers.

Take the Boss 302 for example. Ports were huge but the flow numbers were lacking until high rpm. The velocity was so low that they were dogs at low rpm, but by 6-7k rpm they were killers.

There is always a trade off between CFM and velocity. You have to match things to the RPM you want.

#25

I think one area that has not been addressed here is velocity in the port. Ports flow best with a velocity in the 280-320 FPS range. Of course this assumes the port can handle that kind of velocity. Too much velocity and the column of air slams against the port walls, especially the rear port wall, and this causes a huge disruption in air flow.

You can see this when ports drop off on the high end and the flow numbers flatten out. By high end I mean valve open numbers.

Take the Boss 302 for example. Ports were huge but the flow numbers were lacking until high rpm. The velocity was so low that they were dogs at low rpm, but by 6-7k rpm they were killers.

There is always a trade off between CFM and velocity. You have to match things to the RPM you want.

You can see this when ports drop off on the high end and the flow numbers flatten out. By high end I mean valve open numbers.

Take the Boss 302 for example. Ports were huge but the flow numbers were lacking until high rpm. The velocity was so low that they were dogs at low rpm, but by 6-7k rpm they were killers.

There is always a trade off between CFM and velocity. You have to match things to the RPM you want.

Also, a stock Olds port was not exactly designed with velocity in mind. The EMC entry of Dale Robinson listed above certainly was designed with velocity in mind. It took a lot of effort on his part to get the ports there.

A stock G head flows around 215cfm (my data from a SF-1020 bench, @ 28" h20). So with a port that has a somewhat large cross sectional area, and not a lot of flow, it stands to reason that velocity will be low in the port. Now, the OP stated these heads had a "minor cleanup". I suppose the definition of such should be mentioned I suppose.

Also, according to Darin Morgan of Reher Morrison, any time flow numbers back up at higher valve lift.......that is a bad thing. He claims even if the cam never lifts the valve to where that problem occurs it can still have a huge effect and is causing a disturbance in the port.

#26

All the parameters in the dyno software are set correctly, bore, stroke etc. pulls were done at 600/sec.

My machinist believes that the dyno I use has a really good room, well ventilated etc. however BTRs room is the whole back of his shop soooo.

This engine made 415 raw on another Dyno as it was tearing itself up, with a mismatched intake. It made 490 raw on this one with the mismatch fixed as well as the bearing issue. On top of that it now has the better ring pack and wall finish, so you decide. But it doesn't have the piston the 480 does, THAT one has the best combo, you misunderstood I guess.

This same dyno measured an LS from an airboat just a couple of weeks ago, it made 652 corrected on this one, 646 corrected on another Dyno. So it's 1% off, maybe.

I know you've had it in for me from the start, not sure why but you have. Everything is on the up and up here, no cold temp pulls, no 300/second pulls, none of that. We even weigh the fuel. Normal specific gravity is .73.

As I've said before, imo flow Quality is paramount. And the funny thing is, my head porter routinely estimates the hp number for almost every build I do. Up to this point he's never been off by more than 15-20, that's only a few percentage points. Not sure what other explanation you're looking for. Quite honestly I don't have one.

My machinist believes that the dyno I use has a really good room, well ventilated etc. however BTRs room is the whole back of his shop soooo.

This engine made 415 raw on another Dyno as it was tearing itself up, with a mismatched intake. It made 490 raw on this one with the mismatch fixed as well as the bearing issue. On top of that it now has the better ring pack and wall finish, so you decide. But it doesn't have the piston the 480 does, THAT one has the best combo, you misunderstood I guess.

This same dyno measured an LS from an airboat just a couple of weeks ago, it made 652 corrected on this one, 646 corrected on another Dyno. So it's 1% off, maybe.

I know you've had it in for me from the start, not sure why but you have. Everything is on the up and up here, no cold temp pulls, no 300/second pulls, none of that. We even weigh the fuel. Normal specific gravity is .73.

As I've said before, imo flow Quality is paramount. And the funny thing is, my head porter routinely estimates the hp number for almost every build I do. Up to this point he's never been off by more than 15-20, that's only a few percentage points. Not sure what other explanation you're looking for. Quite honestly I don't have one.

Last edited by cutlassefi; November 12th, 2016 at 06:52 AM.

#28

#29

All the parameters in the dyno software are set correctly, bore, stroke etc. pulls were done at 600/sec.

My machinist believes that the dyno I use has a really good room, well ventilated etc. however BTRs room is the whole back of his shop soooo.

This engine made 415 raw on another Dyno as it was tearing itself up, with a mismatched intake. It made 490 raw on this one with the mismatch fixed as well as the bearing issue. On top of that it now has the better ring pack and wall finish, so you decide. But it doesn't have the piston the 480 does, THAT one has the best combo, you misunderstood I guess.

My machinist believes that the dyno I use has a really good room, well ventilated etc. however BTRs room is the whole back of his shop soooo.

This engine made 415 raw on another Dyno as it was tearing itself up, with a mismatched intake. It made 490 raw on this one with the mismatch fixed as well as the bearing issue. On top of that it now has the better ring pack and wall finish, so you decide. But it doesn't have the piston the 480 does, THAT one has the best combo, you misunderstood I guess.

And why do you keep bringing up BTR? This has nothing to do with his dyno cell, his engines, or anything of that sort.

This same dyno measured an LS from an airboat just a couple of weeks ago, it made 652 corrected on this one, 646 corrected on another Dyno. So it's 1% off, maybe.

I know you've had it in for me from the start, not sure why but you have. Everything is on the up and up here, no cold temp pulls, no 300/second pulls, none of that. We even weigh the fuel. Normal specific gravity is .73.

As I've said before, imo flow Quality is paramount. And the funny thing is, my head porter routinely estimates the hp number for almost every build I do. Up to this point he's never been off by more than 15-20, that's only a few percentage points. Not sure what other explanation you're looking for. Quite honestly I don't have one.

I know you've had it in for me from the start, not sure why but you have. Everything is on the up and up here, no cold temp pulls, no 300/second pulls, none of that. We even weigh the fuel. Normal specific gravity is .73.

As I've said before, imo flow Quality is paramount. And the funny thing is, my head porter routinely estimates the hp number for almost every build I do. Up to this point he's never been off by more than 15-20, that's only a few percentage points. Not sure what other explanation you're looking for. Quite honestly I don't have one.

I understand flow quality as well. A homogenous mixture is key to making power rather than just raw cfm. The stock Olds combustion chamber is not really known for being "state of the art", and we both know the combustion chamber plays a critical role in combustion.

I also mentioned above that stock Ga heads flow 215cfm, has a port volume of 169ccs, and have an average CSA of 2.4sq/in. These are not exactly high velocity ports. Also, with such a shallow valve angle and a short port, it is really hard to introduce swirl into the port design. Did you have the heads flowed or get swirl numbers on them?

To have high velocity ports (which has to do with flow quality) requires a higher cfm as well. If you have a 169cc port that flows 215cfm, and another port of 172cc that flows 268cfm, which one has more velocity (ie: more efficient)?

I point out all of these facts because I find it hard to believe these heads had "minor cleanup". Like I mentioned before, you solicit business off of this forum, and you owe it to everyone here to be as accurate as possible with your work.

I have not once been belligerent towards you. I am simply stating facts and was hoping to have a discussion about these facts like BMEP, volumetric efficiency, required cfm for a given HP number and so on. It seems to me you have no will to do so.

#30

I have no idea what these heads flow. They may flow 150 or 250, I simply don't know. I THINK I had them flowed when I did this build the first time a couple of years ago, but again I honestly don't know.

What I do know is this, this RPM intake is the best one I've ever seen out of the box. The ports are more uniform and larger than any before or after. And I last mentioned Bill T in the context of the dyno room. I was told the one I use is "really good and ventilated". Again similar to Bills'. Not sure what else you want from me. I've stated everything I know about this build, everything.

What I do know is this, this RPM intake is the best one I've ever seen out of the box. The ports are more uniform and larger than any before or after. And I last mentioned Bill T in the context of the dyno room. I was told the one I use is "really good and ventilated". Again similar to Bills'. Not sure what else you want from me. I've stated everything I know about this build, everything.

#31

ANUF-SAID, Put-r-ther Mark!!! You builds speak louder than words here on Classic Olds.

So many awesome reviews from all the Olds engines you have built here. I truly enjoy reading all of them considering ther has been so many ill builds from other builders.

You do awesome work no need to elaborate.

Cheers,

Eric

So many awesome reviews from all the Olds engines you have built here. I truly enjoy reading all of them considering ther has been so many ill builds from other builders.

You do awesome work no need to elaborate.

Cheers,

Eric

#32

76olds, I agree. Mark came highly recommended. Built the 403 mentioned in the small block section and dyno'd same day as this 455. He thought it would do 400hp/450tq but damn I am happy with the 451/512 with stock heads. I was leary at first since I already had been screwed by a "olds engine builder", but Mark is a stand up guy and went above and beyond to make it right.

Last edited by Pete403; November 12th, 2016 at 03:22 PM.

#35

Those are some impressive numbers! Ga heads must be decent heads AND the performer rpm manifold must be much better than previously thought in the dyno testing that was done on here a year or 2 ago!

#39

If I ever build the the 425 for this 64-Pro-Touring F-85 ( currently has a stock rebuild 67 400E) mark is who I'm reaching out too. First thing I have to do is get this car running and on the road!!! Not much longer.....